Catalog excerpts

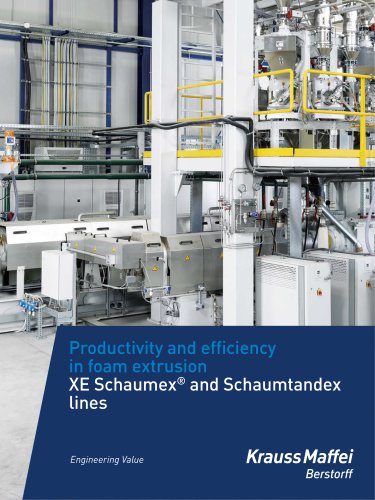

SHEETS, TUBES, PROFILES, BOARDS, BEADS XE Schaumex® and Schaumtandex Lines

Open the catalog to page 1

IN PARTNERSHIP WITH INDUSTRY KraussMaffei is a premium partner for the plastics and rubber processing industries White goods Medical/pharmaceutical Electrical/electronics Whatever you aim to achieve in plastics or rubber processing, KraussMaffei is your partner. We are the only company with intensive expertise across the three main engineering fields. And we have a strong track record in integrating this expertise to develop new processes and systems. Our Injection Moulding Technology Division supplies machines and systems for standard and special applications, very large machines and fully...

Open the catalog to page 2

Secure your competitive edge in foaming - with Schaumex® and Schaumtandex XE Lines For decades, we have designed and built innovative and yet proven technological foaming systems - from foam extruders to complete foaming lines. Thanks to their sophisticated design, our Schaumex® and Schaumtandex XE lines are perfectly suited to meet the most varied demands in physical foaming. These lines give a unique edge to your production: PS, PE and PP can be processed without any changes of the screw and barrel configuration, environmentally compatible blowing agents can be used and start-up material,...

Open the catalog to page 3

PRODUCT INFORMATION IN DETAIL Schaumtandex ZE/KE Lines for high quality requirements and extreme troughput rates Stepping up efficiency in foam extrusion The Schaumtandex ZE/KE combination (comprising a twin-screw extruder for compounding and a single-screw extruder for cooling) is our response to exacting requirements on the mixing efficiency in high-throughput foaming processes. This trend-setting configu- ration incorporates our comprehensive expertise in single- and twin-screw extruder design and physical foaming processes. It combines the outstanding mixing efficiency of a twin-screw...

Open the catalog to page 4

Schaumtandex ZE/KE benefits ■ excellent size-output ratio with high output rates ■ proven mixing efficiency of the ZE-UT series ■ scalability with a view to future requirements, thanks to modular design of the twin-screw extruder's barrel and screw elements ■ use of standard elements from the proven ZE-UT series ■ high process flexibility through variable screw speed and filling degree ■ excellent cooling characteristics of single-screw extruder through the use of barrels with "wet" liners and pressurised water for temperature control Schaumtandex ZE/KE lines suitable for a wide range of...

Open the catalog to page 5

50 K E1 50 /K E2 50 E1 /K K E1 20 0/ K E9 K Th r ou gh p E1 ut 20 (k g/ h) Schaumtandex KE/KE throughput rates 1,000 100 10 Schaumtandex KE120/KE150 PRODUCT INFORMATION IN DETAIL Schaumtandex KE/KE lines – the cost-effective solution for output rates of up to 900 kg/h Proven technology for medium proven technology along with an exceptionally throughput rates sturdy machine design. Schaumtandex KE/KE lines Our Schaumtandex KE/KE combination (compris- are a cost-effective solution for throughput rates ing a single-screw extruder for compounding and a of between 250 and 900 kg/h. second...

Open the catalog to page 6

Schaumex® 90 ISO-TUBE PRODUCT INFORMATION IN DETAIL Schaumex® lines – maximum productivity combined with minimum space requirements System variants Schaumex ® throughput rates ha um ex ® 15 0 Sc ex ® 12 Sc ha um ex ® 90 um ha Sc Sc ha um ut Th ro ug hp of the blowing agent and melt cooling – all in a single extruder with thoughput rates of up to ex ® 60 (k g/ process: compounding, injection and incorporation 0 h) The Schaumex ® line concept for the entire foaming 320 kg/h. 1,000 100 10 Schaumex® lines: compact and sturdy machine design Product information in detail Page 7

Open the catalog to page 7

STANDARD FEATURES Active melt seal, excellent cooling characteristics and constant solids feeding - Active melt seal Schaumtandex extruders equipped with the patented active melt seal (ASD) set new standards of reliability for sealing the processing section at the gear box end. Sensitive foaming processes using liquid or gaseous blowing agents, some- times in high concentrations, plus high system pressure, call for constant operating conditions, which we support with our active melt seal. The active melt seal essentially consists of an addi- tional barrel element with oil temperature...

Open the catalog to page 8

STANDARD FEATURES Modular design, special screw elements and optimum processing sections - Modular design In the design of the screw elements and barrel units of our ZE extruders we have applied a strictly modular concept. This supports an almost unlimited range of variants and options to choose from for a screw-barrel configuration that precisely matches your process requirements. Our range of screw elements comprises: ■ Conveying elements in various lengths and pitches, multi-flighted, closely intermeshing with self-sealing profile, or with flight edge profile and increased free screw...

Open the catalog to page 9

PRODUCT INFORMATION IN DETAIL Top quality film and sheets for any application - produced on Schaumex® and Schaumtandex ISO-PAC and ISO-TUBE lines Whether expanded polystyrene, light polyethylene foam, heavy polyethylene or polypropylene foam - Schaumex® and Schaumtandex ISO-PAC lines produce the right sheet for any application: ■ packaging material, especially for food and electrical appliances ■ building material, especially for impact sound insulation ■ technical articles such as seals, edge protection strips, and cover seals ■ roof linings, seals, armrests, and impact protection for the...

Open the catalog to page 10

Foam insulation tubes made of PP, PE, and PE/EVA have firmly established themselves in the area of heating, sanitary, and air conditioning installations. Foamed edge protection sections are widely used in the furniture industry. Foamed fun articles for swimming pools are made in a wide range of types and shapes. All these products, and many more, can be produced in consistently high quality using our ISO-TUBE Schaumex® and Schaumtandex lines. The four-die tube head specially designed for the ISO-TUBE line provides for reduced line speed at constant output rate. There is no need to inter-...

Open the catalog to page 11All KraussMaffei catalogs and technical brochures

-

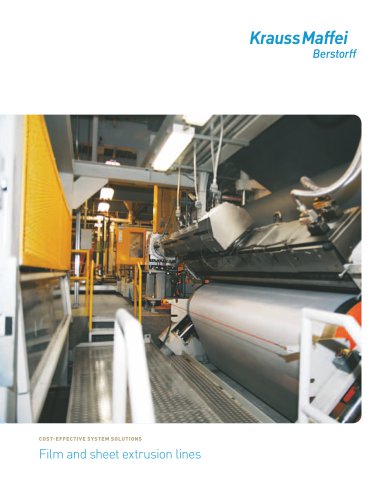

Film and sheet extrusion lines

24 Pages

-

Complete system solutions

16 Pages

-

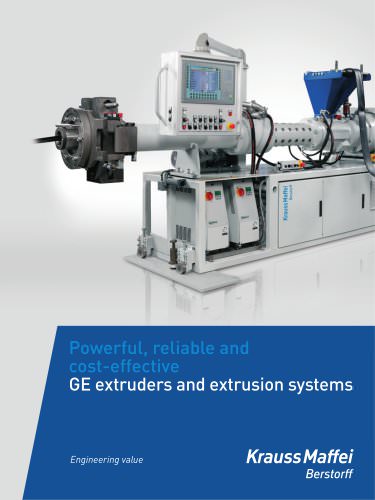

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

AHEAD 2014

28 Pages

-

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

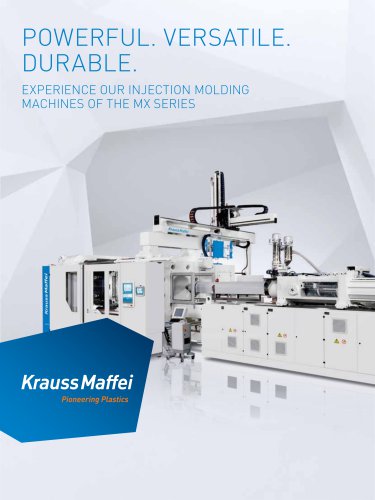

MX injection molding machines

20 Pages

-

Machines in the GX Series

26 Pages