Catalog excerpts

MORE FLEXIBILITY AND LOWER COSTS IN PIPE EXTRUSION QuickSwitch system for in-line dimension change

Open the catalog to page 1

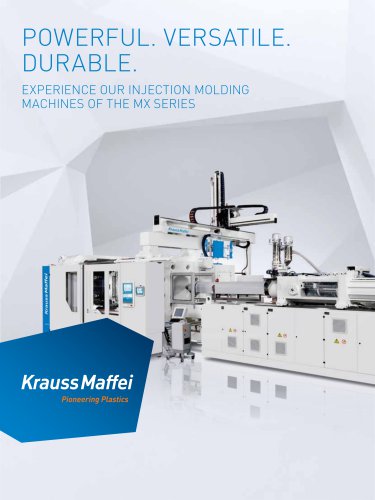

IN PARTNERSHIP WITH INDUSTRY KraussMaffei is a premium partner for the plastics and rubber processing industries Automotive White Goods Construction Life Sciences Electrical/Electronics Whatever you aim to achieve in plastics or rubber processing, KraussMaffei is your partner. We are the only company with intensive expertise across the three main engineering fields. And we have a strong track record in integrating this expertise to develop new processes and systems. Our Injection Molding Machinery Division supplies machinery and systems from 35 to 4,000 tonnes for standard applications and...

Open the catalog to page 2

Change pipe dimensions without stopping Changing pipe diameter or wall thickness on a conventional pipe extrusion line means stopping the line, resetting line components and finally starting the line again. KraussMaffei Berstorff's QuickSwitch system changes pipe dimensions during running production - at the touch of a button. QuickSwitch saves costs and it's You have the choice of investing in a complete QuickSwitch system, or converting an existing con- ventional line module by module, first to a manually operated QuickSwitch system and then to a fully automated line. You can be sure that...

Open the catalog to page 3

TRANSPARENT TECHNOLOGY Meet the machine: take a tour of a QuickSwitch Line for PO pipe, outer diameter range 25 - 63 mm Haul-off/saw combination Flexible end seal Choice of optional units: ■ Marker (QuickSwitch version) ■ Multilayer pipehead (QuickSwitch version) ■ Stripe and outer-layer adapter ■ Winder with quick adjustment ■ Socketing machine with fast change fitting Spray bath with flexible pipe supports

Open the catalog to page 4

QuickSwitch control system master production line control Gravimetric melt throughput with flexible pipe support system, vacuum system, water-level and flow metering, all controlled via QuickSwitch line control Single-screw extruder

Open the catalog to page 5

The calibrating basket is a key QuickSwitch component. Page 6

Open the catalog to page 6

DETAILED PRODUCT INFORMATION QuickSwitch more than meets market requirements for cost savings and flexibility Trends in the pipe market are more and more towards extremely short order turnaround and small batches of pipe in different dimensions. With QuickSwitch technology (patent # EPi 115 pipe dimensions (single and multilayer), within the system's set range, virtually on demand without the cost of maintaining a large inventory. QuickSwitch pipehead: adjustable On a conventional system, almost every dimension change necessitates changing the dieset at the pipehead - the mandrel and the...

Open the catalog to page 7

Core components of a versatile QuickSwitch system for PVC pipe: pipehead, suction bell and calibrating basket QuickSwitch suction bell: high-precision action The suction bell is located between the pipehead and the calibrating basket, with efficient seals to each side. Its function is to expand the flexible tube of melt to the calibrating diameter, if the required diameter is larger than the maximum die diameter QuickSwitch calibrating basket: smoothly The key component of every QuickSwitch line is the adjustable calibrating basket. By contrast with a conventional calibrating system which...

Open the catalog to page 8

Detailed product information

Open the catalog to page 9

QuickSwitch end seal: reliable and adjustable To build up the necessary underpressure, the vacuum tank must have efficient seals on the intake and exit sides. In the intake zone, the seal is created by the calibrating basket together with the resin tube itself. The vacuum tank exit needs a special end seal. A conventional pipe extrusion system is fitted with a seal specific to one pipe diameter only. In a QuickSwitch line, the end seal consists of a number of movable segments. This segmented construction, in combination with air pressure, ensures that the vacuum tank is always sealed off...

Open the catalog to page 10

• Extruder output • Pipe dimensions • Pipehead setting • Underpressure in the suction bell • Diameter in the calibrating basket • Vacuum tank position • Underpressure in vacuum tank • Take-off speed • Contact pressure of the haul-off pads on the pipe The required data record is simply selected and activated at the touch of a button. Within minutes, the whole QuickSwitch line adjusts automatically to the chosen pipe dimensions. After producing a couple of meters of waste pipe during the change- over, the system quickly stabilizes to produce pipe Instead of investing in a new, complete...

Open the catalog to page 11

Economic and process advantages are built in - it's over to you to exploit them In recent years, there has been continuously grow- ing demand for more flexible pipe extrusion lines, for profitable production of small batches, for lines capable of longer, sustained production runs, and for more cost-effective production. Krauss- Maffei Berstorff has responded to these demands by teaming up with egeplast Werner Strumann GmbH to develop the innovative QuickSwitch technology. The ability to change pipe dimensions at the touch of a button, during running produc- tion, has huge potential for cost...

Open the catalog to page 12

Single-layer HDPE pipe PVC pipe Multilayer HDPE pipe Products and applications Page 13

Open the catalog to page 13

SERVICE WORLDWIDE Service, support and spare parts - when you need them, where you need them Rely on us for a fast and competent response to all your service needs anywhere in the world. Whatever you need - from troubleshooting and training to spares or repairs - we're on the job. We're dedicated to supplying service quality on a par with the outstanding quality of our machines and systems. We offer far more than spare parts and hotlines. We'll work with you to choose the best and most cost-effective solution for your operation. We'll help you test new applications and we'll plan customized...

Open the catalog to page 14

Worldwide hotline Email: service-ext.ukHkraussmaffei.com Krauss Maffei Corporation Email: service-ext.usHkraussmaffei.com Krauss Maffei de México Mexico City, México Krauss Maffei do Brasil Ltda KraussMaffei Technologies GmbH Munich, Germany Customer Service Phone: +49 89 8899-2273 (electrical systems] Phone: +49 89 8899-4380 (mechanical systems] Application Engineering Abbiategrasso, Italy Moscow, Russia KraussMaffei Technologies Pune, India Krauss-Maffei Extrusion Jiaxing City, China international service or spare parts teams by post, use this address: Extrusion Technology Service...

Open the catalog to page 15All KraussMaffei catalogs and technical brochures

-

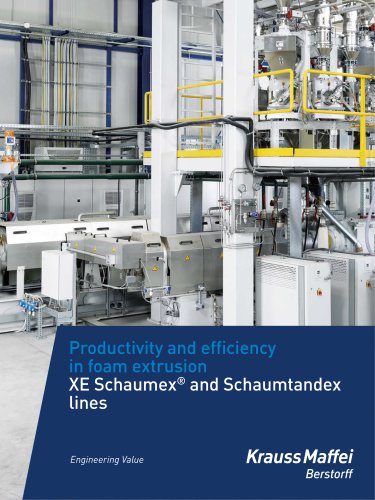

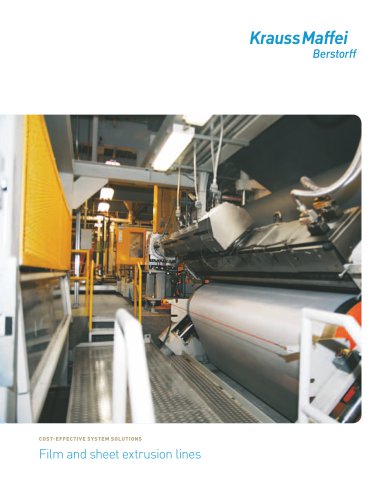

Film and sheet extrusion lines

24 Pages

-

Complete system solutions

16 Pages

-

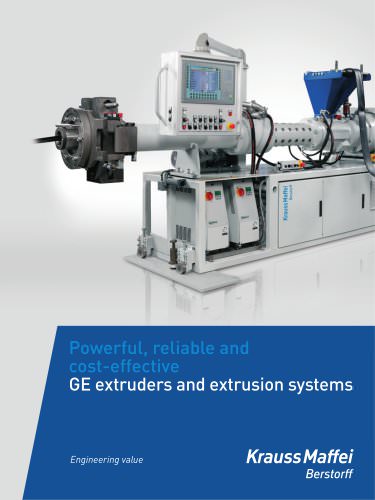

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

AHEAD 2014

28 Pages

-

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

MX injection molding machines

20 Pages

-

Machines in the GX Series

26 Pages