Catalog excerpts

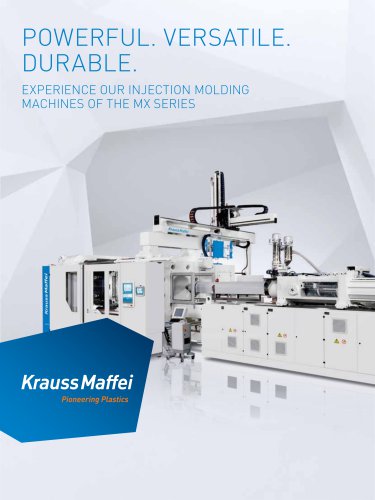

COMPACT 2-PLATEN MACHINES FOR THE BIG JOBS MX injection molding machines

Open the catalog to page 1

IN PARTNERSHIP WITH INDUSTRY KraussMaffei is a premium partner for the plastics and rubber processing industries worldwide White Goods Life Sciences Whatever you aim to achieve in plastics or rubber complete extrusion lines – is used in many processing, KraussMaffei is your partner. We are industries, including chemicals, pharmaceuticals, the only company with intensive expertise across automotive, construction, furniture and packaging. the three main engineering fields. And we have a strong track record in integrating this expertise to develop new processes and systems. We are the “people...

Open the catalog to page 2

MX injection molding machines for fast responses, fast cycles and high productivity KraussMaffei is among the market leaders in engineering large injection molding machines. The MX series is highly successful and available in the clamp force range from 850 to 4000 t. MX machines are engineered to deliver sustained performance under demanding conditions. They are able of delivering fast responses, fast cycles and high productivity. Versatile and modular they offer a wide range of configurations for optimized, applicationspecific solutions. Standard machines can be upgradedwith minimal effort...

Open the catalog to page 3

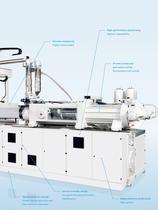

TRANSPARENT TECHNOLOGY Meet the machine: take a tour of an MX injection molding machine Proven 2-platen technology High stiffness and space-saving construction Absolute platen parallelism Longer mold life and premium part quality User-friendly MC 5 control system Lucid, error resistant, freely Outstanding machine dynamics Highest productivity

Open the catalog to page 4

High-performance plasticizing Highest repeatability Extreme modularity Highly customizable Proven screws and non-return valves Outstanding melt quality Service-friendly design Optimized drive concept Power-saving operation and fast machine responses For quick and easy preventive maintenance Highly effective oil filtration High uptime

Open the catalog to page 5

DESIGN BASICS The MX series – setting new benchmarks for big injection molding machines All the modules that make up an MX machine machine is ready for integration in an existing operate smoothly and efficiently together. Key processing line, using existing molds. elements are the 2-platen clamp, the injection unit and the hydraulic system. All MX machines More modularity operate under the operator-friendly MC 5 micro- KraussMaffei MX machines are as modular as they processor control system. The process in progress come. This means big benefits for our customers, is clearly visualized on...

Open the catalog to page 6

Possible combinations of injection units and clamp units listing available screw diameters

Open the catalog to page 7

DETAILED PRODUCT INFORMATION 2-platen clamp unit: Compact, fast, low-maintenance Compact and easy on the mould Multi-phase mold protection The design of the mold fixing platens has been The multi-phase mold protection mechanism can optimized using the Finite Element Method (FEM). be precisely set to protect the mold against damage. This guarantees optimal application of force and This extends mold service life and helps to keep minimal deformation, even for very large molds. maintenance costs low – both these factors have a The platens’ rugged “box” construction ensures positive effect on...

Open the catalog to page 8

Moving platen as a rugged, FEM-optimized box structure For mold opening, all four tiebars are unlocked Self-lubricating guide bushings and slides ensure simultaneously, allowing fast mold movement. long-term, reliable, low-maintenance operation. The system has been designed for very fast locking/unlocking and precise positioning. Very fast locking/unlocking When the mold is shut, the tiebars are locked in place behind the moving platen by the intermesh ing elements of the mechanical locking system. View inside a locking element Locking element and clamp force cylinder for very fast machine...

Open the catalog to page 9

DETAILED PRODUCT INFORMATION Injection unit: high-precision performance, wear resistant, minimal cleaning effort The MX series has the right injection unit and account of these factors are more cost-effective. the optimal screw geometry for every production This is why KraussMaffei offers not only standard task. A tightly scaled choice of working capacities screws, but also special mixing screws and high per- and screw diameters makes it possible to match formance screws (HPS-UN, HPS-AT). Work on new injection unit performance to product requirements. screw generations to meet continuously...

Open the catalog to page 10

Hydraulic direct screw drive for highest repeatability and quality High-precision injection units Enhanced wear protection For plasticizing, a hydraulic drive for the rotational The main factors influencing wear on the screw, movement of the screw is standard. An electric barrel and check valve are the material formula- drive is an option, if production considerations tions being processed and the plasticizing rate. require plasticizing in parallel with other machine Additives used to improve processing stability, or movements. Force is transferred directly to the to give the end product...

Open the catalog to page 11

DETAILED PRODUCT INFORMATION Hydraulics: precision control, fast response, flexible upgrades Energy-saving pump drive Dependable control valves At each processing stage, the regenerative pump All speed and pressure variables for controlling MX drive supplies precisely the oil volume necessary to operation are entered as digital values. The electroni- generate the required pressure. Energy consumption cally activated proportional valves, monitored by an additional internal control circuit, ensure high repeat ability and maintain set values over long production Fast response times runs....

Open the catalog to page 12

Easy and maintenance-friendly access to all hydraulic valves in the injection unit and clamp Hydraulic components are linked to the central oil-cooled drive motors have an additional sound- machine control system via advanced bus technology. reducing effect. The drive unit itself is completely This guarantees fast and reliable data processing enclosed in a soundproof housing, which further and immunity to interference – internal or external. reduces noise emissions. The actual noise emission The result is outstanding product quality and high machine availability – the best route to a good...

Open the catalog to page 13All KraussMaffei catalogs and technical brochures

-

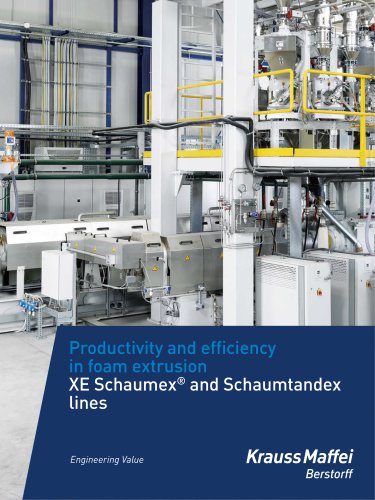

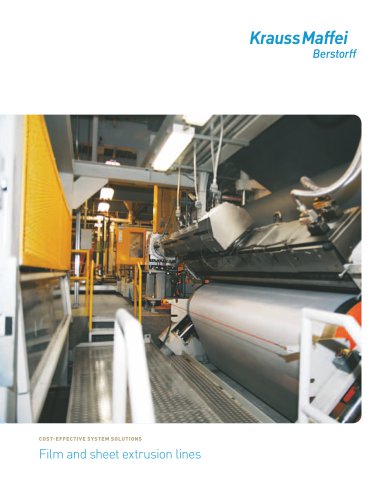

Film and sheet extrusion lines

24 Pages

-

Complete system solutions

16 Pages

-

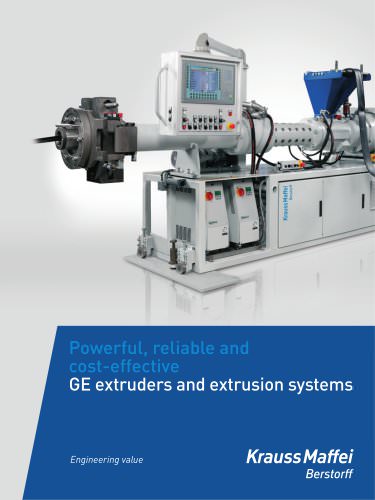

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

AHEAD 2014

28 Pages

-

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

Machines in the GX Series

26 Pages