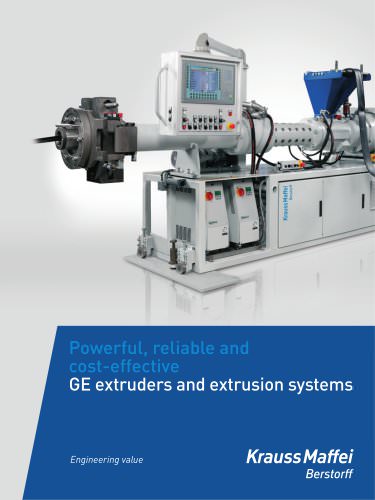

Maximum Flexibility, high Product Quality, optimum cost effectiveness ZE twin-screw extruders

30Pages

Catalog excerpts

Maximum Flexibility, high Product Quality, optimum cost effectiveness Engineering Value

Open the catalog to page 1

Maximum flexibility combined with outstanding availability in plastics processing Base your planning on extruder concepts that: – asily provide the uncompromising flexibility e required for state-of-the-art production of the most varied products – nsure high availability throughout the entire e service life – onvince by their unparalleled productivity c and cost-effectiveness Bank on KraussMaffei Berstorff‘s excellent plant engineering competence in plastics processing: optimize your production and sharpen your competitive edge by complete system solutions, turnkey production lines and...

Open the catalog to page 3

Technical data Specialized machinery for special tasks: 12 sizes with particular benefits AUSKLAPPER AUßEN Six of the 12 ZE machine sizes – the ZE 25 UTX up to the ZE 75 UTX – are designed as UTX models. This design concept is distinguished by its particularly compact layout and the very high degree of operator friendliness and ease of maintenance. The ZE UTX laboratory and small batch extruder is available in A and R versions as well as in an A/R combination and in Ultra Glide version. The Ultra Glide has a drive unit, which enables the whole extruder drive unit with both screws to be...

Open the catalog to page 4

AUSKLAPPER INNEN 2 Barrel cooling and heating

Open the catalog to page 5

Technology made transparent First encounter: take a closer look at the ZE UTX twin-screw extruder 1 Drive train Our ZE extruders are characterized by above-average torque obtained by a special power branching system in the gear unit. Application of the latest in modern gearing technology has resulted in a very compact design and extremely low noise levels. A combined dip and pressure lubrication system protects the bearings and gears. If an overload occurs, a safety coupling instantaneously separates the drive from the extruder. 6 C-clamp barrel connectors W ith the C-clamp connectors,...

Open the catalog to page 6

2 Barrel cooling and heating B arrel elements with a new type of heating and cooling system provide direct and intensive heat transfer and/or cooling. This allows the process in the extruder to be optimized by precise temperature control and dynamic control mode. Heating is done by high-power heating cartridges, which work faster and thus give more rapid start-up. The optimized layout and arrangement of the cooling bores provide high-efficiency counter-flow cooling with standard injection of high-pressure water or steam. 4 Side-feeders T he enlarged twin-screw side-feeder unit gives...

Open the catalog to page 7

AUSKLAPPER AUßEN 6 C-clamp barrel connectors

Open the catalog to page 8

AUSKLAPPER AUßEN

Open the catalog to page 9

ZE twin-screw extruders Process implementation with utmost precision Process implementation with utmost precision The most precise way to run your process. Two concepts – one basis: 12 sizes each in two versions 24 extruder types in ZE-UTX/UT version 24 twin-screw extruders in two versions with 12 sizes each are available for performing the process steps involved in the manufacture of your products – efficiently and technically optimized. Both KraussMaffei Berstorff ZE-A and ZE-R extruder ranges present the same screw shaft center distance, making screws and barrels interchangeable when...

Open the catalog to page 10

ZE-A version The ZE-A range, with an outer/inner screw diameter ratio of D/d = 1.46, offers an optimal relationship between free volume and torque, high screw torque and the highest throughput capacity. The ZE-A is thus especially suitable for high-performance compounding, alloying, filling and reinforcing, masterbatch production and the processing of powders or small-particle polymers. ZE-R version The ZE-R version has a big free volume. It features high residence times, high free volume with high torque, optimal melt surface renewal, low gas velocities and minimal shear energy input. Its...

Open the catalog to page 11

ZE twin-screw extruders Perfect fine-tuning for any application Perfect fine-tuning for any application Do you know a more flexible building block system? Two barrel section lengths for each screw diameter. Barrel sections and screw elements are designed in strict accordance with the building block principle. With various types and different specifications that can all be combined with great versatility, there is virtually no limit to the barrel and screw configurations, which can be employed to meet your process requirements in the finest detail. The patented hardening method (DE 101 122...

Open the catalog to page 12

In the case of twin-screw extruders of the ZE UT series, wear protection for machine sizes ZE90 UT and larger is accomplished by using solid nitriding steel barrels, barrels with through-hardened CrMo liners or barrels made of composite materials. The selection of the type of wear protection depends on the application the extruder is used for and on the specific conditions of wear. Barrel sections with an L/D ratio of 4 or 6 are available for the configuration of the modular processing section. These barrel sections are designed as – pen barrels for feed zones, o – pen barrels equipped with...

Open the catalog to page 13

Laboratory extruders Twin-screw laboratory extruders Constant quality production – the fastest solution ZE 25 UTX and ZE 26 Basic – the right choice for your laboratory With KraussMaffei Berstorff you don’t have to rely on hypothesis when launching new products or introducing new processes. The ZE 25 UTX and ZE 26 Basic laboratory extruders offer all features of our production-scale extruders. The process parameters developed on these machines in the laboratory can directly be transferred to your production lines. Ultra Glide – the drive train for immediate process evaluation A further...

Open the catalog to page 14

ZE twin-screw extruders ZE UT / UTX Quality planning requires in-depth know-how For your quality control – a wealth of experience gathered from almost 2,500 applications 3 To ensure the future success of your company, KraussMaffei Berstorff twin-screw extruders are tailored to the specific requirements of your products and processes. Based on our in-depth know-how in all plastics compounding and extrusion applications and our design skills as experienced machine engineering company, we supply extrusion lines that are perfectly suited to your recipes and production processes. Benefit from...

Open the catalog to page 16All KraussMaffei catalogs and technical brochures

-

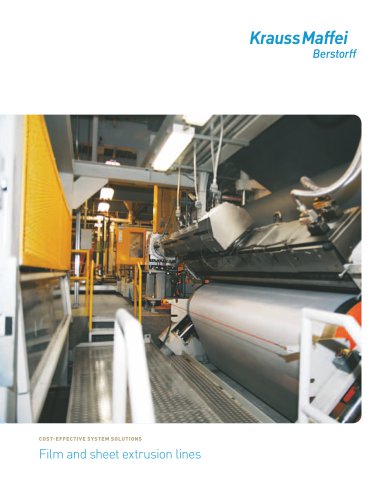

Film and sheet extrusion lines

24 Pages

-

Complete system solutions

16 Pages

-

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

AHEAD 2014

28 Pages

-

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

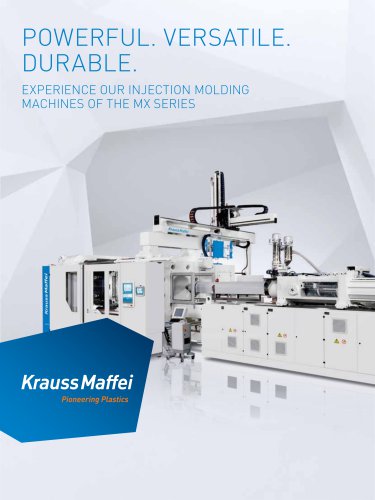

MX injection molding machines

20 Pages

-

Machines in the GX Series

26 Pages