Catalog excerpts

Versatile tools for productive Engineering passion

Open the catalog to page 1

Industrial robots in the IR series Facts and figures Flexible. Powerful. Effective. Industrial robots in the IR series Facts and figures Areas of application Consumer goods White goods Insertion, demolding, machining, installing Special features Versatile, high rigidity, great degree of freedom, investment security, cleanroom-compliant Working space Standard accessories Gripper, quick changing units, belt conveyors, linear axis (7th axis), protective housings Control system concept Integrated (in combination with a KraussMaffei injection molding machine) or stand-alone (for injection...

Open the catalog to page 2

Transparent technology Take a tour of the IR series 5 CE conformity, free of charge High degree of assurance – low costs Flexibility is critical Space-optimized production units or mobile assembly cells Proven energy and signal routing Attachment unit or gripper interface module Simple operating concept Programming – setting – operating Economical turnkey solutions Technologically sophisticated and advanced Safe home traverse at the touch of a button No collision

Open the catalog to page 3

Industrial robots in the IR series Flexible concepts Flexibility is critical No limits for your requirements KraussMaffei provides you space-optimized production units and mobile cells with the shortest return to service time, according to your requirements. Our industrial robots implement complex demolding processes with various gripper concepts through six axes, freely programmable sequences of movements and wide swiveling ranges. Heavy-duty basic units Industrial robots are designed for extreme ambient conditions and continuous operation – for example, when welding body components. When...

Open the catalog to page 4

Industrial robots in the IR series Assembly and installation variants Assembly and installation We have the optimal solution for your production KraussMaffei provides you with four basic options to integrate the industrial robots of the IR series perfectly into your specific production situation. Space-saving production cell: The shelf-mounted version Our shelf-mounted (S) version industrial robot is usually installed on the fixed (mold) platen of the injection molding machine. This solution is primarily used for large machines with over 650 tons clamping force and high-volume components....

Open the catalog to page 5

Industrial robots in the IR series Technical and economical advantages Technical and economical advantages are included And easy for you to use The IR series from KraussMaffei provides you with various advantages. A simple operating and control concept and a uniform interface and CE conformity. Simple operation and control concept Industrial robots are highly complex. With our intelligent operation and control concepts, however, this is not a problem. The user-friendly "5-button operation concept" can be applied directly with the robot handheld remote or on the panel of the injection...

Open the catalog to page 6

Industrial robots in the IR series Range of applications Range of applications Multifaceted performance for your system solution Demolding – rom simple demolding parts to overF molded parts with large volume Packaging – In cartons, trays, blisters and sachets – In the clean room – Counted Bumpers for the automotive industry Various fittings Insertion – f fed parts, such as electric compoO nents and intricate clips – f preprocessed, for example, O pre-punched, parts – f process-specific, heated parts O Encapsulation – nsert molding of raw glass, I including clips Example: Rear windows...

Open the catalog to page 7

Industrial robots in the IR series Peripherals and remote service Versatile peripherals For complex automation solutions Most varied of grippers Whether simple grippers with standard components such as vacuum exhausters, parallel grippers, sprue gate grippers or complex inserting and demolding grippers, we have the perfect solution for you. Benefit from economical solutions with high holding force for your special requirements. Different drawer systems They are used for providing parts, exporting QS components and for buffer storage. In addition to single and double drawers, a combination...

Open the catalog to page 8

Industrial robots in the IR series Co-operative project handling Almost automatic: Our co-operative project handling Together towards success in just seven steps Step 1 Project meeting Step 3 Layout design 1. Detailed project meeting We work together with you to appraise the current state of your production, and discuss the pros and cons of existing production lines and concepts, and work out any potential improvements that could be made. In addition to this exchange of experience, we work with you to draw up an initial outline schedule for your planned project. 2. Drawing up different...

Open the catalog to page 9

Industrial robots in the IR series Application examples The IR series is optimally equipped for many tasks Loading airbag nets and mounting clips Industrial robots in the IR series open up great potential for you in automation of injection molding machines that go far beyond the standard demolding process. Take advantage of our wide and varied offering and profit from our experience. The customer W eidmann Plastic Technology AG International technology developer for the automotive industry, medical, sensors and plumbing technology. The focus is on the development and series production of...

Open the catalog to page 10

Industrial robots in the IR series Practical examples Application example Assembly cell for snap nuts The customer Biro Edwin Bischof AG, Switzerland Development and production of advanced technical molded parts from thermoplastic plastics. The specialist for multi-component technology for various industries: automotive, consumer goods, construction and electrical. The task Installation of snap nuts on interior automobile parts in a stand-alone cell. The challenge The exact feed and the process-reliable installation of 12 snap nuts on various positions on the finished part and the demand...

Open the catalog to page 11

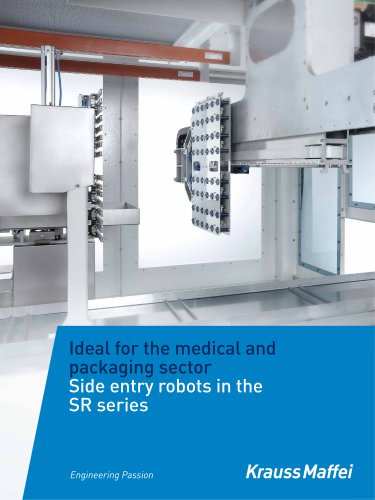

Industrial robots in the IR series Further information Further information which might also interest you Are you looking for a linear or side-removal robot? We can provide you the right robot for every production task. We have also compiled extensive information on the subject of service for you. This will help you increase the flexibility of your injection molding machines and robots for ever newer process requirements, and continuously increase their capacity. We are happy to provide you with detailed information on this. For example, ask us about: – Linear robots of the LRX/LRX-S series...

Open the catalog to page 12All KraussMaffei catalogs and technical brochures

-

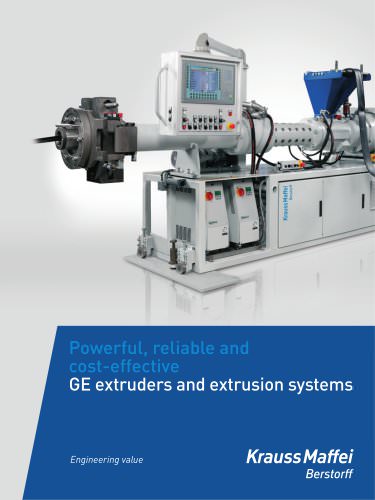

Film and sheet extrusion lines

24 Pages

-

Complete system solutions

16 Pages

-

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

AHEAD 2014

28 Pages

-

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

MX injection molding machines

20 Pages

-

Machines in the GX Series

26 Pages