Catalog excerpts

High quality covering of rolls, tubes, sleeves and rods Roll covering machinery, strip winding, Covermatic and crosshead systems Engineering Value

Open the catalog to page 1

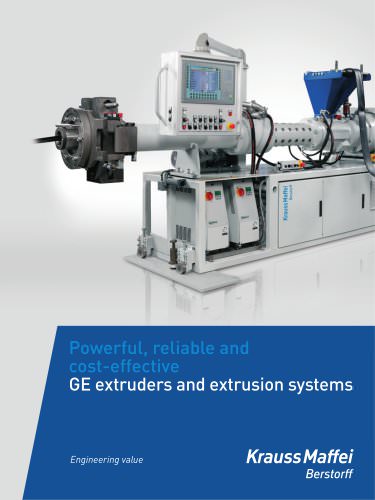

Roll covering machinery Constantly high product quality thanks to perfect interaction of all components involved All components of KraussMaffei Berstorff roll c overing lines are precisely coordinated to provide safe and reliable operation. Your benefits at a glance – quipped with extruders of different sizes E and designs, these roll covering lines ensure p erfect processing of a wide variety of rubber compounds. – he extruders used for this application stand T out for high output rates and low stock temperatures combined with a long service life. – he fully automatic lines are...

Open the catalog to page 3

Roll Covering Machinery Strip Winding Strip Winding Optimal process technology for high-quality products Strip winding unit with GE 90 KS x 12D extruder Strip winding is ideal for all diameters of rollers, from very small to very large and for longer-length rollers. The machine consists of a travelling baseframe, a winding and application unit, the electrical controls and an extruder, which is matched to the processing requirements of the rubber and to the required output. Standard benefits – lexible use of different KraussMaffei F Berstorff high-performance extruders – traight-through...

Open the catalog to page 4

Strip winding machines with straight-through Roller core Roller length Covering thickness Strip thickness Strip width Strip speed Strip winding units with Mini-Roller Head Roller core Roller length Covering thickness Strip thickness Strip width Strip speed Central operator panel Dependent on extruder type and size, rubber compound and strip section. Extruder type For high outputs and quality with wide variety of rubber types For high outputs at lowtemperatures For high outputs and quality with wide variety of rubber types and low temperatures Straight application Inclined application

Open the catalog to page 5

Roll Covering Machinery Covermatic Covermatic Precision roller covering The Covermatic enables the extrudate to be applied directly onto the roll core or other round stock. Covermatic is particularly suited to the production of totally homogeneous, b lister-free coverings with a minimum of grinding allowance and with excellent concentricity and straightness. Rubber compounds with mooney v iscosities of 20 – 110 can be processed. Rollers covered with the covermatic s atisfy all the high quality demands of printing and painting applications. We offer this system in 3 sizes to cater for...

Open the catalog to page 6

Covermatic 200 N Core d 160 mm, covering thickness 20 mm 40 shore A Standard benefits – Excellent quality of covering – igh precision covering needs H m inimum grinding allowance – Careful processing of the compound – egassing ensures no air inclusions D or inconsistencies – Little or no post-extrusion work – imple and rapid changes of size S or compound type – Optimal material utilisation – Easy to operate via central panel – Low manning requirements – Rapid turn-round times – Automated covering process – tate-of-the-art electrical controls S with PLC and operator panel – Recipe storage...

Open the catalog to page 7

Roll Covering Machinery Covermatic Covermatic KH 200N Kern d 130 mm; Schichtdicke 18 mm, Kernlänge 4.200 mm; 65 Shore A Covermatic Process descriptions The rubber, which has been plastified and homogenised in the feeding extruder, is fed directly to the hollow driven screw of the Covermatic extrusion head. In the crossover zone, there is a facility for straining and/or degassing of the r ubber. A vacuum unit, supplied with the machine, prevents any air inclusions occuring during the covering process. The multi-flight hollow screw conveys the compound via the guide tube and mouthpiece to...

Open the catalog to page 8

KraussMaffei Berstorff GE 120 K x 16D Crosshead for core d 10 – 65 mm Crosshead Extrusion Economic system for simple uses Crosshead extrusion units round off our roller covering range. They are well suited to applications where several r ollers of the same size have to be covered using the same rubber type. The use of different sized units allows cores diameters from 5 – 200 mm to be covered to thicknesses from 2 – 20 mm. Our experienced engineers work with the customer to select the correct size and type of crosshead for their requirements (with or without hydraulic guiding and...

Open the catalog to page 9

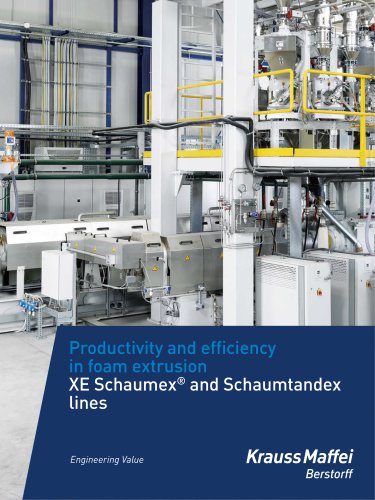

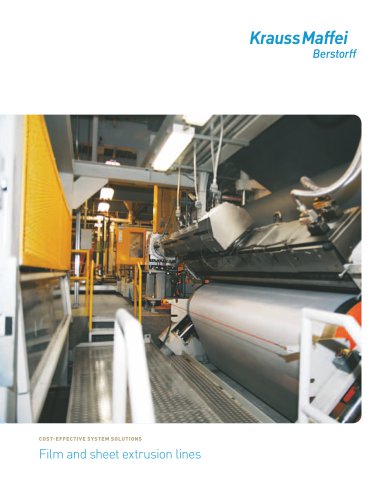

Roll Covering Machinery Further information Further information This might also be of interest to you You can find additional information on KraussMaffei Berstorff extrusion solutions in the following brochures: – Plastics technology – Twin-screw extruders – Foam extrusion lines – Film and sheet extrusion lines – Pipe and profile extrusion lines – Plastics calenders Rubber technology – Extruders and extrusion lines – Rubber calenders – ubber and TPE profile R production lines – Rubber sheet lines – Roll covering machinery You will find our brochures and flyers on other topics online at:...

Open the catalog to page 10

KraussMaffei Berstorff A strong brand in a unique global group Value-proven extrusion technology solutions Around the world, KraussMaffei Berstorff stands for reliable and value-proven solutions in extrusion technology. These range from using individual extruders for degassing in polymerization, compounding, pipe, profile, film and sheet extrusion, physical foaming and the manufacture of technical rubber articles and intermediates for tire production up to complete extrusion lines. All machines and systems from KraussMaffei Berstorff are custom-configured for the chemical, automotive,...

Open the catalog to page 11

High quality covering of rolls, tubes, sleeves and rods Roll covering machinery, strip winding, Covermatic and crosshead systems The fully automatic lines are designed for rapid and precise coating of roll cores, tubes or rods with different rubber coverings for the metal, paper, t extile, printing, electrical and wood industries. 1.0 LD. 2nd edition 09/13. EXTH 006 A PRO 09/2013 EN ··· Subject to technical changes. All components of KraussMaffei Berstorff roll c overing lines are precisely coordinated to provide safe and reliable operation. Equipped with extruders of different sizes...

Open the catalog to page 12All KraussMaffei catalogs and technical brochures

-

Film and sheet extrusion lines

24 Pages

-

Complete system solutions

16 Pages

-

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

AHEAD 2014

28 Pages

-

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

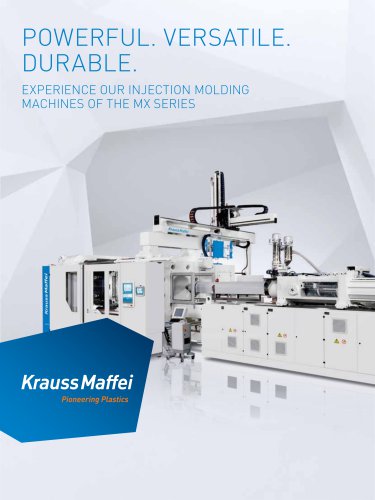

MX injection molding machines

20 Pages

-

Machines in the GX Series

26 Pages