Catalog excerpts

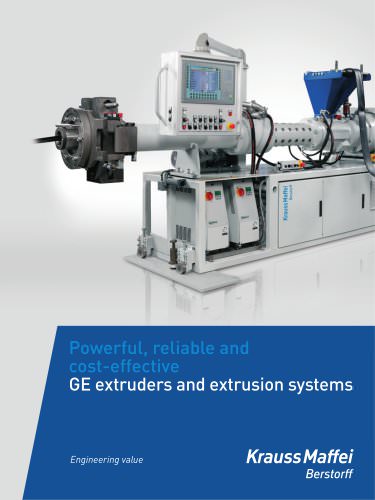

GE extruders and extrusion systems Engineering value KraussMaffei

Open the catalog to page 1

Rubber extruders Practical examples Premium quality products from a wide Various components Automotive hoses Industrial hoses Multi-component sealing profiles Sealing profiles Coated rollers forthe automotive industry forthe construction Steel wire rope and Neoprene materials Printing blankets textile conveyor belts

Open the catalog to page 2

Powerful, reliable and cost-effective GE extruders and extrusion systems A rubber extruder must be prepared for the high requirements of rubber product manufacturing to the greatest extent p ossible, in order to ensure continuous use and to contribute to the profitable success of a company. From proven extruders from the GE-K series to GE-SC Pinconvert extruders, the same principles of success apply for every model: high quality, m aximum availability and flexibility as well as perfect integration into the treatment process. The advantages at a glance – High output – ow-maintenance...

Open the catalog to page 3

First encounter: Take a tour of the cold-feed GE-K rubber extruder Flexible machine design – The process unit and drive can be combined on an individualized basis Fast commissioning – Ready-to-use delivery High user friendliness – Short set-up times – Easy maintenance

Open the catalog to page 4

Cold-feed GE-K rubber extruder Efficiency and reliability for simple treatment processes The cold-feed rubber extruders from the GE-K series are the ideal machines for simple treatment processes. It only requires a little space in order to show its strengths due to its compact design. Its high degree of automation makes it an easy-tooperate machine. The GE-K series offers high production reliability thanks to high product quality, established reliability and high recoverability. High-performance machine design The GE-K series is designed to be plug-and-go, so that it can be commissioned...

Open the catalog to page 5

First encounter: Take a tour of the cold-feed GE-KS pin-barrel rubber extruder Flexible machine design – he process unit and drive can be T combined on an individualized basis High user friendliness – Short set-up times – Easy maintenance Fast commissioning – Ready-to-use delivery High product quality – rocess unit with pin barrel and P optional vacuum degassing

Open the catalog to page 6

Cold-feed GE-KS pin-barrel rubber extruder Flexibility and reliability without compromise GE-KS and Vac GE-KS pin- barrel rubber extruders are a ll-around machines for a wide variety of applications. Their flexibility and reliability make them true success machines in the treatment process. The attractiveness of pin-barrel extruders is enhanced even f urther by the expansive suite of series equipment, such as an automatic pin adjusting device, replaceable wet sleeves, a pin breakage display and high-performance screws. The advanced technology processes a wide spectrum of rubber...

Open the catalog to page 7

SC series extruders Maximum flexibility Cold-feed GE-SC Pinconvert rubber extruders Maximum flexibility for demanding tasks A defining feature of the KraussMaffei Berstorff GE-SC Pinconvert® extruder is a throttle element built into the area near the maximum c hannel volume of the sleeve. It has pins distributed symmetrically around the circumference that radially penetrate into the channels of the barrel sleeve. These can be adjusted manually or electrohydraulically and allow the channel volume to be reduced to zero in this area. Because this allows the output, melt temperature and...

Open the catalog to page 8

Hot-feed GE-W rubber extruder High-performance extruder with proven technology Hot-feed KraussMaffei Berstorff GE-W series extruders have proven themselves in manufacturing a wide assortment of n atural and artificial rubber products. They are fed as units downstream of roller mills, either continually with strips or intermittently with rolls of uncured rubber. They evenly shape the pre-heated plasticized rubber. In addition, they can be arranged as discharge extruders directly below internal mixers. In this form they receive screws with larger diameters and tamping dies as a means of...

Open the catalog to page 9

High-performance filtration device for highest mixtur clarity Rheologic optimized flow channels – without corner and edge Screenchanger with hydraulically pushing system – to simply changing of the screens

Open the catalog to page 10

The innovative system for clean mixtures and high efficiency Strainer systems are the ideal investment for the future for many manufactures of rubber articles; they reliably remove contamination from rubber mixtures. The result: Clean mixtures for manufacturing premium quality sealing profiles, hoses or sheets. KraussMaffei Berstorff strainer systems are outfitted with innovative components to reduce setup time and increase productivity. The various mesh sizes provide the mixture with highest possible purity. Modular design for maximum throughput The strainer systems can be configured and...

Open the catalog to page 11

Extrusion heads Fast mold change Extrusion heads Fast mold change and short cleaning times The extrusion heads from KraussMaffei Berstorff ensure excellent product quality and providing excellent productivity at the same time. The heads are installed on the extruder with connections that are pressure-tight up to 600 bar. The connections are opened and closed automatically or manually in a few easy steps. The optimized flow c hannels distribute the entire mass of rubber to the extrusion heads for a wide variety of products. Hydraulically adjustable duplex extrusion head The program...

Open the catalog to page 12

Control technology Process-oriented operator guidance for easy machine operation Central system control High demands on product quality call for high process reliability. As one of the most modern control, regulation and monitoring systems in the area of extrusion, the KraussMaffei Berstorff control system features reliable technology and intelligent functions for central system control. It ensures optimized production preparation and transparent production conditions at a constantly high level. Optimum visualization even for several extruders The individual units in a machine can be...

Open the catalog to page 13All KraussMaffei catalogs and technical brochures

-

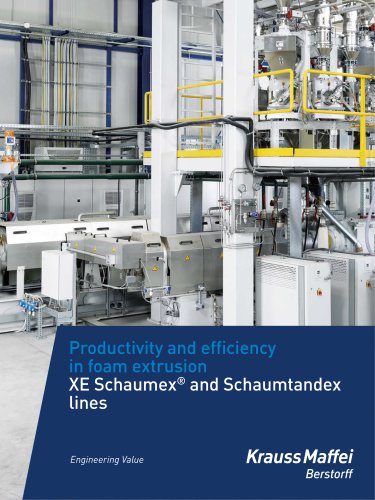

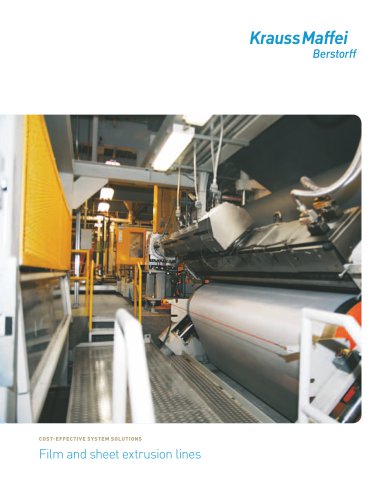

Film and sheet extrusion lines

24 Pages

-

Complete system solutions

16 Pages

-

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

AHEAD 2014

28 Pages

-

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

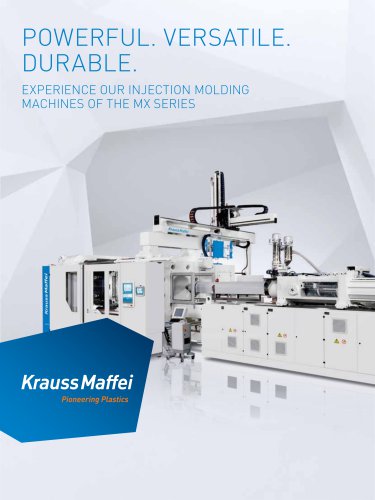

MX injection molding machines

20 Pages

-

Machines in the GX Series

26 Pages