Catalog excerpts

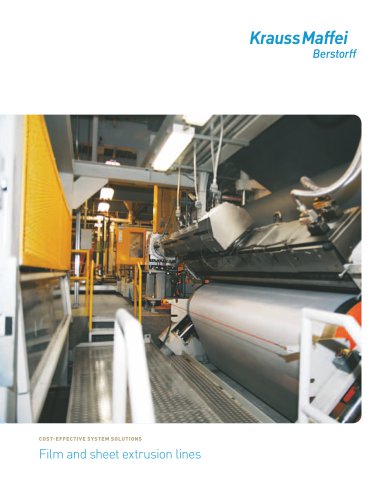

Cost-effective system solutions Film and sheet extrusion lines

Open the catalog to page 1

IN PARTNERSHIP WITH INDUSTRY KraussMaffei is a premium partner for the plastics and rubber processing industries worldwide White Goods Life Sciences Whatever you aim to achieve in plastics or rubber complete extrusion lines – is used in many processing, KraussMaffei is your partner. We are industries, including chemicals, pharmaceuticals, the only company with intensive expertise across automotive, construction, furniture and packaging. the three main engineering fields. And we have a strong track record in integrating this expertise to develop new processes and systems. We are the “people...

Open the catalog to page 2

Producing cost-effective high-quality plastics film and sheets has never been easier! It couldn’t be easier – in its capacity as a system provider, KraussMaffei Berstorff offers all services involved in manufacturing high-performance extrusion lines – from plant logistics, engineering and actually building the line up to operator training and production assistance. It couldn’t be cheaper – with ZE twin-screw extruders polymer melts can be processed and shaped in a single cycle on the basis of favourably priced raw materials and at increased output rates. Recycling of edge trimming and web...

Open the catalog to page 3

System solutions System provider for optimum results Single- or two-stage process – uncompromising Special styling wishes of designers, exacting func- flexibility. Better quality, improved production re- tional requirements of safety engineers or excellent liability, higher cost-effectiveness... KraussMaffei user-friendly handling features can all be easily satis- Berstorff’s tailor-made technology is the ideal fied with KraussMaffei Berstorff‘s extrusion systems. solution for producing high-quality plastic film and sheets. Innovation comes from experience. In order to compete successfully...

Open the catalog to page 4

PRoDuCt infoRmAtion in DetAil Optimum production sequence – with alternatives for the individual process stages single- or twin-screw extruders. KraussMaffei Berstorff ZE co-rotating twin-screw When configuring your film/sheet extrusion or lami- extruders are used for the production of high-quality nating line, you can rely on KraussMaffei Berstorff thermoforming sheet at throughput rates exceeding to have the extruder best suited to your specific 1,000 kg/h, especially for processing undried PET, product and your production process: from single- for the production of engineering film and...

Open the catalog to page 5

Co-rotating twin-screw extruder Downstream equipment Counter rotating twin-screw extruder KraussMaffei Berstorff extruders are always the Polishing calenders: right way to maximise process flexibility. Thanks to two systems – many variations. the great variety of series and versions available in KraussMaffei Berstorff polishing calenders are sizes ranging from 45 to 150 mm for single-screw available with various roll arrangements and extruders and from 25 to over 200 mm for twin- always offer an optimum cost-effective solution screw extruders, KraussMaffei Berstorff can always for your fi...

Open the catalog to page 6

Downstream equipment: winding or stacking? ..are the ideal polishing calenders for producing Every single component in the downstream equip- crystal-clear sheets and fi lm from PMMA, PC, ment of our fi lm and sheet extrusion lines has been PETG and SAN with excellent optical properties. designed to meet the needs of the future: state-of- Owing to the variable arrangement of rolls 1 and the art technology yet sturdy, reliable and designed 3, the calender unites all the process engineering for maximum throughput rates. benefits offered by the standard horizontal, inclined or vertical roll...

Open the catalog to page 7

Standard thermoforming sheets Simple implementation, compact design and fast amortisation Extrusion with single-screw extruders and KraussMaffei Berstorff standard thermoforming selected modules sheet lines are available in three different sizes for You do not need a degree in rocket science to figure throughput rates from 550 kg/h to 1,500 kg/h and out why KraussMaffei Berstorff‘s standard thermo- sheet widths between 400 and 2,000 mm. forming sheet lines are so cost-effective. The four modules that make up the thermoforming sheet line are perfectly matched and based on a modular Typical...

Open the catalog to page 8

State-of-the-art thermoforming sheet line – reliable, long lasting and cost-effective 1 Feeding system 2 ingle-screw extruder with screen changer, S melt pump, wide extrusion die and feedblock 3 3-rolls polishing calender 4 ost-cooling section with thickness gauge and P take-off unit 5 Accumulator and winder Standard thermoforming sheets

Open the catalog to page 9

High-quality thermoforming sheet lines Optimized production lines with customized equipment Meet the best... for quantity with quality · 100% use of reclaimed material (edge trims, KraussMaffei Berstorff thermoforming sheet lines start-up scrap, web scrap), for in-line compounding of thermoforming sheets · gentle raw material compounding, offer unparalleled cost-effectiveness in the produc- · compact, space-saving design. tion of high-quality sheets for the most diverse packaging applications. The twin-screw extruders Uncompromising performance. of these lines are designed to combine the...

Open the catalog to page 10

Twin-screw extruder with slot die and smoothing unit for the production of highquality thermoforming sheets 1 Differential metering station with gravimetric feeders 2 Twin-screw extruder with screen changer, melt pump, wide extrusion die and feedblock 3 3-rolls polishing calender 4 Post-cooling section with thickness gauge and take-off unit 5 Accumulator and winder High-quality thermoforming sheet lines

Open the catalog to page 11

Fabric-reinforced sheets Cost-effective lines for lamination on one or both sides Comprehensive solution – even with in-line 3,600 mm can be produced with this equipment at throughput rates of up to 4,5 tonnes per hour. KraussMaffei Berstorff extrusion and lamination lines always offer an optimum cost-effective solution Perfection in every single layer! for your sheet production requirements. They have KraussMaffei Berstorff extrusion and lamination proved their worth in the daily production of the lines combine all production steps into a single most diverse fabric-reinforced sheets for a...

Open the catalog to page 12All KraussMaffei catalogs and technical brochures

-

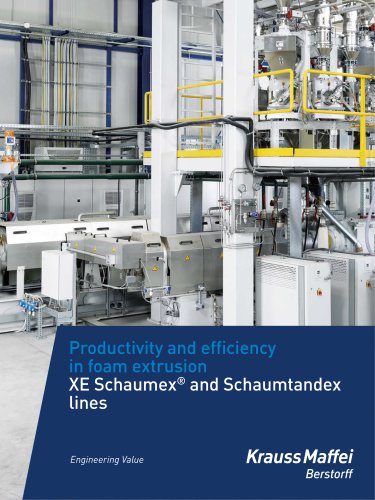

Complete system solutions

16 Pages

-

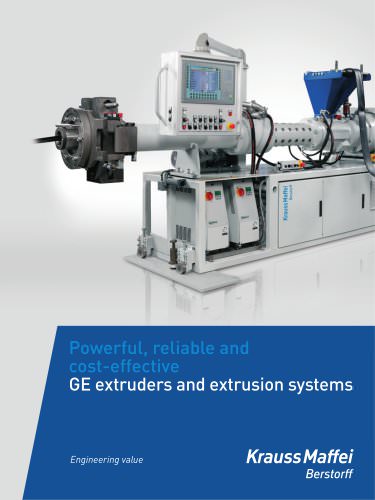

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

AHEAD 2014

28 Pages

-

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

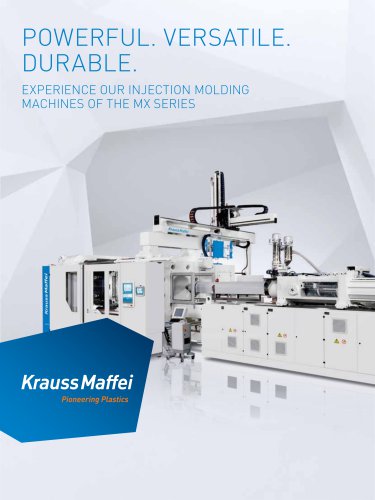

MX injection molding machines

20 Pages

-

Machines in the GX Series

26 Pages