Catalog excerpts

Thinking in systems Extrusion technology for plastics and rubber products Engineering Value

Open the catalog to page 1

Extrusion technology Partners of industry KraussMaffei Berstorff – a powerful brand within a unique global-player group Stable-value extrusion solutions KraussMaffei Berstorff is synonymous with reliable and sustainable extrusion solutions at inter ational n scale. Applications include degassing during p olymerization, compounding, pipe, profile, film and sheet extrusion or physical foaming right through to the production of technical rubber products and semi-finished tire components on stand-alone extruders or complete extrusion lines. All machines and lines are tailored to customer...

Open the catalog to page 2

Extrusion technology At a glance Extrusion technology at a glance – full scale flexibility puts you on the safe side! Engineering value KraussMaffei Berstorff holds a unique position in the plastics and rubber processing industries – we offer extrusion package solutions that are reliable and stable in value. Using innovative technologies, we strive at enhanced cost-effectiveness and even higher efficiency in tomorrow’s production. The KraussMaffei Berstorff brand is well-positioned in almost all markets and in all market segments worldwide. This is what our unique “Engineering Value” p ...

Open the catalog to page 4

KraussMaffei Berstorff’s key asset: qualified staff The design and construction of extrusion lines involves in-depth process engineering know-how and longstanding experience. This is why highly competent and experienced staff in the development, manufacturing, assembly, marketing, sales, service and administrative divisions are a must. That is the crucial point: a company is only as good as the employees who work for it! The mission of our deeply committed cross-national project teams is to secure our leading position in the fierce international competition. Systemized service Our service...

Open the catalog to page 5

Extrusion technology Plastics processing

Open the catalog to page 6

Part 1 Plastics technology KraussMaffei Berstorff plastics e xtrusion lines stand for maximum p roduct quality – from compounding, pipe extrusion up to film and sheet production.

Open the catalog to page 7

Extrusion technology Plastics processing Single-screw extruders from 250 mm to 800 mm screw diameter KraussMaffei Berstorff builds single-screw e xtruders for mixing, degassing and compounding. The KE 800 extruder with a screw diameter of 800 mm is the world’s largest single-screw extruder. In LDPE synthesis for melt pellet conversion, throughput rates of up to 74 metric tons per hour are achieved. One key step in compounding is the degassing of hydrocarbons and other volatile matter from the melt. This reduces the need for post-treatment of the pellets in silos and protects the...

Open the catalog to page 8

Left: The world’s largest single-screw extruder for melt degassing Right: Underwater pelletizer with an output rate of up to 74 metric tons/h Pelletizers KraussMaffei Berstorff underwater pelletizers have proven their value as compact and efficient downstream units. Together with our single-screw extruders, they form a system for efficient thermoplastics compounding. Areas of application for KraussMaffei Berstorff pelletizers include: – olyolefin production (LDPE) with throughput rates p of up to 50 metric tons per hour; – olypropylene compounding with filler content of p 50% and more....

Open the catalog to page 9

Extrusion technology Plastics processing Compounding systems with ZE twin-screw extruders – highly flexible and productive Maximum flexibility for high product quality KraussMaffei Berstorff ZE compounding systems are engineered to meet the specific requirements of products and processes as if tailor-made. Thanks to comprehensive process expertise in all key areas of application and unparalleled design skills of its experienced mechanical engineers, KraussMaffei Berstorff can offer customers extrusion systems that are adapted precisely to their formulations and processes. These include: –...

Open the catalog to page 10

KraussMaffei Berstorff ZE UTX for a wide range of processing tasks – egassing of volatile components, such as water, D monomers, oligomers, solvents – oncentration of polymer solutions and reclaim C of solvents – Polymerization and recondensation – epelletizing regrind and agglomerate, also sheet R and fiber scrap – Compounding regrind, e.g. butyl rubber – roduction of masterbatches, such as pigments, P flame-retardants, blowing agents and filler concentrates – Producing natural fiber reinforced plastics KraussMaffei Berstorff Twin-Screw Extruders Email: twinscrew-ext.de@kraussmaffei.com

Open the catalog to page 11

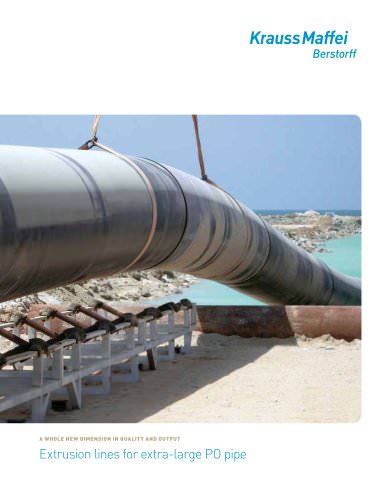

Extrusion technology Plastics processing Pipe extrusion – application-specific solutions System expertise in pipe extrusion As a system supplier, KraussMaffei Berstorff s upplies extrusion lines for producing plastic pipes from 5 to 2500 mm diameter – including auto ation m components to maximize material savings. Our product portfolio covers single-screw xtruders, e counter-rotating and co-rotating twin-screw e xtruders, pipe heads and all downstream components, supplied either separately or as complete extrusion lines with any level of automation. To maximize savings on materials,...

Open the catalog to page 12

KraussMaffei Berstorff pipe extrusion lines for PE, PP, PP-R and PE-X as well as for corrugated and aluminum composite pipes we offer complete system solutions for the production of complex pipes, both standard and special. Opening up a world of options in pipe extrusion – rinking water pipes, sewage pipes D – Irrigation pipes, drainage pipes – Hot water and heating pipes – Cable conduits – Gas pipes – Multilayer pipes – SRP pipes, PE-X pipes, RTP pipes – o-extruded pipes in different material C c ombinations, PVC foam-core pipes – Aluminum composite pipes – Highly-filled pipes –...

Open the catalog to page 13

Extrusion technology Plastics processing Profile extrusion – from single machines to complete production lines Flexibility in profile extrusion Our product portfolio for high-performance profile extrusion ranges from 32D conical and parallel twin-screw extruders to co-extruders for integrated extrusion systems in piggyback or tandem configurations. In addition, our machine spectrum includes parallel twin-screw extruders for standard applications in the medium output range. We also supply application-specific solutions for high-performance extrusion, for flexible output of window profiles...

Open the catalog to page 14All KraussMaffei catalogs and technical brochures

-

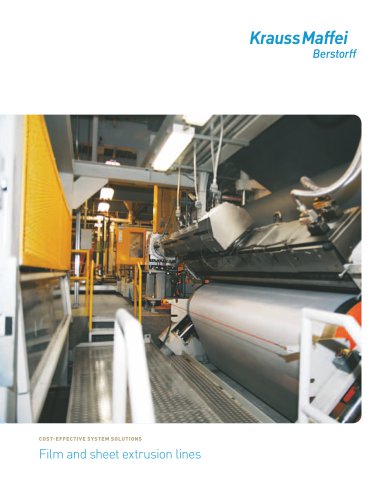

Film and sheet extrusion lines

24 Pages

-

Complete system solutions

16 Pages

-

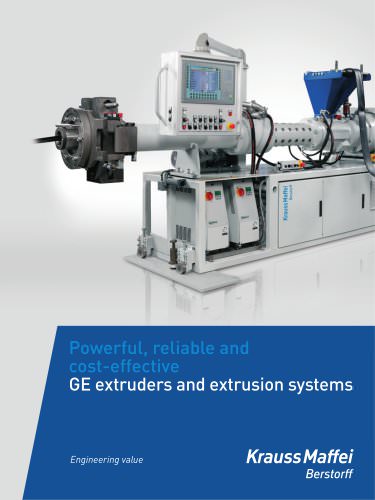

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

AHEAD 2014

28 Pages

-

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

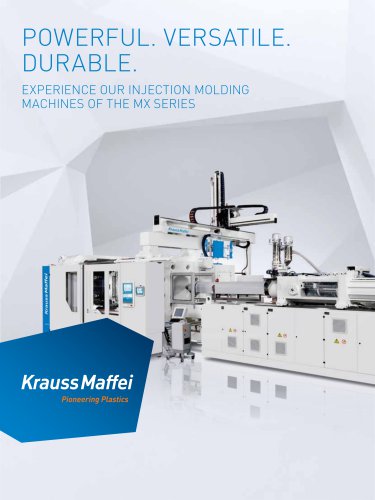

MX injection molding machines

20 Pages

-

Machines in the GX Series

26 Pages