Catalog excerpts

Extrusion technology for plastics

Open the catalog to page 1

IN PARTNERSHIP WITH INDUSTRY rubber processing industries Whatever you aim to achieve in plastics or rubber processing, KraussMaffei is your partner. We are the only company with intensive expertise across the three main engineering fields. And we have a strong track record in integrating this expertise to develop Supplying solutions for any application By integrating the extrusion operations of Krauss- Maffei and Berstorff in the single KraussMaffei Berstorff brand, we have strengthened our position as a system supplier capable of offering single- vendor solutions for all the main plastics...

Open the catalog to page 2

The Extrusion Technology Division supplies machi- nery and systems for compounding, for pipe, profile and sheet extrusion, physical foaming, and the pro- duction of technical rubbers and intermediates for tire production. Our machinery - from single extru- ders to complete extrusion lines - is used in many industries, including chemicals, pharmaceuticals, automotive, construction, furniture and packaging. We are your partners from the first exploratory discussion, through development to commissioning, servicing and operating your system. At all times, you are assured of outstanding...

Open the catalog to page 3

Dr. Hans Ulrich Golz Managing Director What extrusion systems can do today would have been unimaginable only a few years ago. And the trends towards ever more differentiated appli- cations and new and more cost-efficient processes are gaining momentum. They are driven by the need to produce ever better products and to keep a tight grip on manufacturing costs. The building industry is just one sector where pioneering innovations have revolutionized the market in recent years. With a wealth of new products and international patents, KraussMaffei Berstorff has been at the cutting edge of new...

Open the catalog to page 4

Manfred Reichel Our aim is to become the preferred system partner for our customers worldwide. To this end, the extrusion division is steadily expanding its network of sales and service centres outside Germany. We are there for our customers all over the world. We guarantee a fast and efficient response to their problems and queries and offer high-quality service and consulting. We are committed to becoming technology leaders not merely by supplying excellent machinery and systems, but also through delivering outstanding process stability, competitive advantage and local presence for our...

Open the catalog to page 5

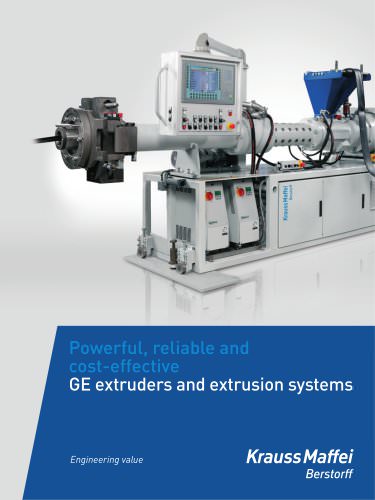

The world's largest single-screw extruder for melt PLASTICS TECHNOLOGY Single-screw extruders KraussMaffei Berstorff builds single-screw extruders for mixing, degassing and compounding. The KE 800 extruder with a screw diameter of 800mm is the world's largest single-screw extruder. In LDPE syn- thesis for melt pellet conversion, throughput rates of up to 74 tonnes per hour are achieved. One key step in compounding is the degassing of hydrocarbons and other volatile matter from the melt. This reduces the need for post-treatment of the pellets in silos and Pelletising systems KraussMaffei...

Open the catalog to page 6

Underwater pelletizer with throughput rates of up to downstream units. Together with our single-screw extruders they form a system for compounding Areas of application for KraussMaffei Berstorff pelletisers include: ■ polyolefin production (LDPE) with throughput rates of up to 74 tonnes per hour ■ polypropylene compounding with filler content KraussMaffei Berstorff Single-Screw Extruders Email: singLescrew-ext.de@kraussmaffei.com

Open the catalog to page 7

PLASTICS TECHNOLOGY Compounding systems with twin-screw extruders Maximum flexibility for high product quality KraussMaffei Berstorff ZE compounding systems are engineered to meet the specific requirements of the products and processes as if tailor-made. Based on our comprehensive process expertise, drawn from all the key areas of application, and its design skills as experienced mechanical engineers, KraussMaffei Berstorff can offer customers extrusion systems that are adapted precisely to their formulations and processes, for example for ■ incorporating reinforcing agents and fillers,...

Open the catalog to page 8

■ Producing adhesives and hot-melt adhesives ■ Degassing of volatile components, such as water, monomers, oligomers, solvents ■ Concentration of polymer solutions and reclaim ■ Repelletizing regrind and agglomerate, also sheet ■ Compounding regrind, eg, butyl rubber ■ Production of masterbatches, such as pigment, flame-retardants, blowing agents and filler ■ Producing natural fiber reinforced plastics KraussMaffei Berstorff Twin-Screw Extruders Email: twinscrew-ext.de@kraussmaffei.com

Open the catalog to page 9

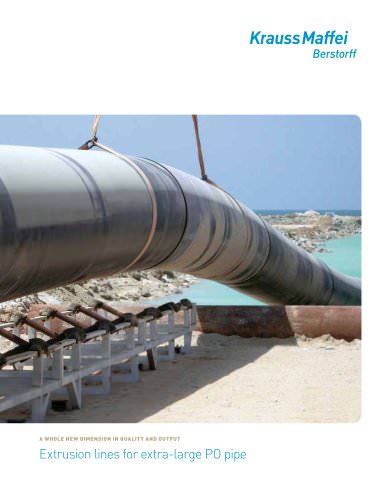

PLASTICS TECHNOLOGY System expertise in pipe extrusion As a system supplier, KraussMaffei Berstorff supplies extrusion lines for producing plastic pipe from 5 to 2500 mm diameter - including automation compon- ents to maximize material savings. Our product port- folio covers single-screw extruders, counter-rotating and co-rotating twin-screw extruders, pipeheads and all downstream components, supplied either sepa- rately or as complete extrusion lines with any level of automation. To maximize savings on materials, energy and costs, without compromising on product quality, we developed...

Open the catalog to page 10

KraussMaffei Berstorff pipe extrusion lines for PE, composite pipe ■ Drinking water pipe ptions in pipe extrusion different material KraussMaffei Berstorff Pipe Extrusion Email: pipe-ext.de@kraussmaffei.com

Open the catalog to page 11

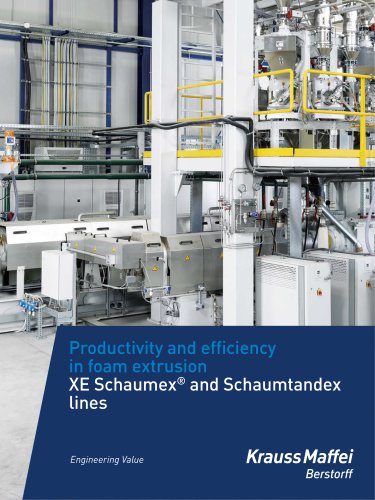

PLASTICS TECHNOLOGY Foam extrusion lines KraussMaffei Berstorff plans and builds reliable, high-performance systems for physical foaming. We draw on our extensive expertise in the areas of single- and twin-screw extruders, the latest calculation processes and the test facilities available Depending on the version and equipment, our foam extrusion lines are suitable for processing PS, PE, PP and other high-grade polymers and co-polymers for producing boards, sheets, beads and pipes. Our systems allow environmentally compatible blowing Areas of application for foam products produced on...

Open the catalog to page 12

KraussMaffei Berstorff Schaumtandex lines for the production of insulating tubes and XPS boards Sound-proofing, insulation of walls and ceilings for the construction industry, packaging film, food trays, thermal packaging of medicines, lid seals for glass containers, microwave-safe food packaging for the packaging industry, graphic boards, automotive applications. For areas subject to pressure and humidity, for example for insulating cellar walls and floors. Non-foamed minigranulate (EPS) for processing High-grade, foamed pellets (EPP) for the efficient production of high-quality re-usable...

Open the catalog to page 13All KraussMaffei catalogs and technical brochures

-

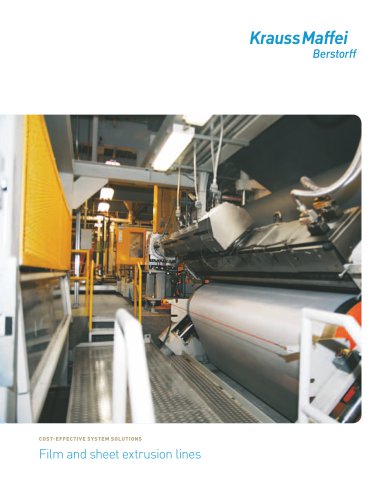

Film and sheet extrusion lines

24 Pages

-

Complete system solutions

16 Pages

-

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

AHEAD 2014

28 Pages

-

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

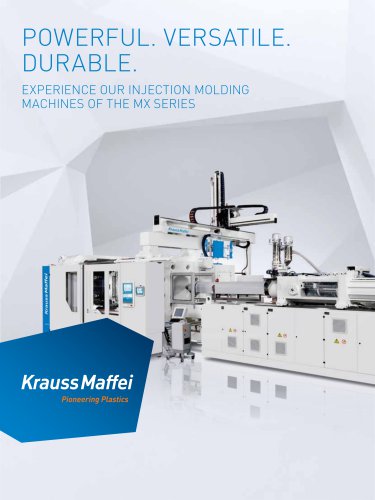

MX injection molding machines

20 Pages

-

Machines in the GX Series

26 Pages