Catalog excerpts

Excellent processing reliability Extrusion lines for the production of silicone rubber hoses and profiles Engineering Value

Open the catalog to page 1Product details Silicone rubber extrusion lines Engineering highlights Machinery for silicone rubber in uncompromising KraussMaffei Berstorff quality Silicone rubber lends itself to a wide variety of uses. Thanks to its many different characteristics, it offers ideal solutions for the most varied applications. Extruder for silicone rubber processing KraussMaffei Berstorff’s product p ortfolio includes machines and lines designed for the extrusion of solid s ilicone rubber hoses and profiles. E ngineering and construction of such machinery require in-depth material know-how and...

Open the catalog to page 2Engineering highlights Design features Extruder – Extruder sizes of 45, 60 and 90 mm with an L/D-ratio of 10 – Screw geometries with high intake v olume tailored to the processing of silicone rubber – Barrel, screw, die, feed zone and feed roll are all cooled to maximize output rates Shock module – re-vulcanization at temperatures of P up to 600° C by means of black body ceramic infrared heaters or short-wave infrared radiators – ontactless material passage to avoid C damage to the product outside Hot-air channels – hort heating times, direct heating S of the channel air – recise...

Open the catalog to page 3Excellent processing reliability for versatile material Our solution for future challenges in the extrusion of silicone rubber hoses and profiles These lines are fed with silicone rubber strips. The extruders combined with carefully matched downstream equipment are tailored to the specific material properties. Hoses and profiles are partly produced under clean room conditions and used for applications that require: – maximum flexibility and minimum bending radii; – high temperature and pressure resistance; – ntistatic properties; a – water-repellent surfaces; – asy cleaning using...

Open the catalog to page 4All KraussMaffei catalogs and technical brochures

-

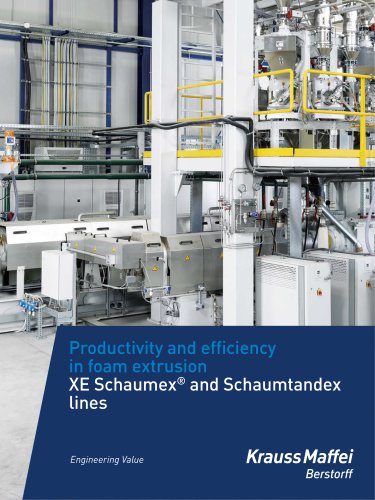

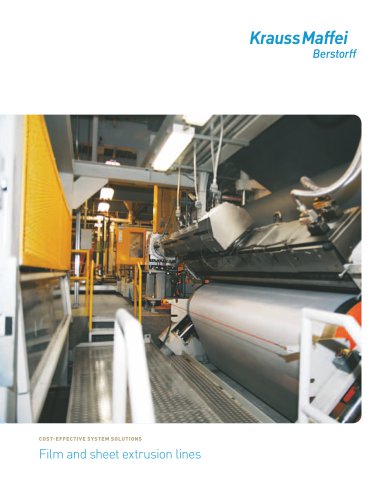

Film and sheet extrusion lines

24 Pages

-

Complete system solutions

16 Pages

-

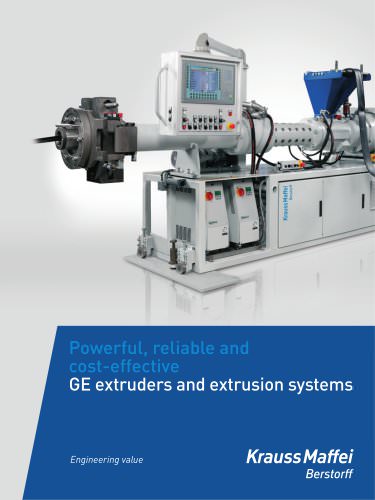

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

AHEAD 2014

28 Pages

-

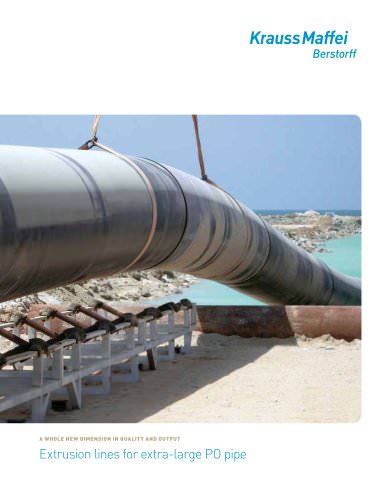

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

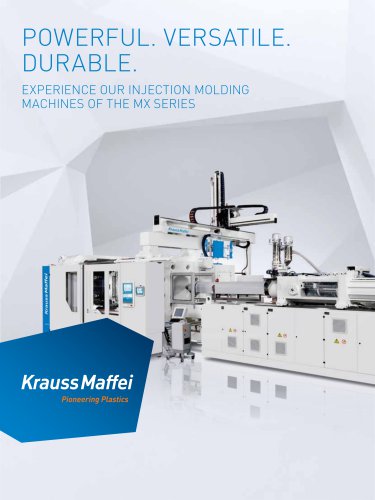

MX injection molding machines

20 Pages

-

Machines in the GX Series

26 Pages