Catalog excerpts

ALL-ELECTRIC MACHINE CONCEPT - HIGHLY PRODUCTIVE, CLEAN AND PRECISE EX series injection molding machines

Open the catalog to page 1

IN PARTNERSHIP WITH INDUSTRY KraussMaffei is a premium partner for the plastics and rubber processing industries worldwide White Goods Life Sciences Whatever you aim to achieve in plastics or rubber complete extrusion lines – is used in many processing, KraussMaffei is your partner. We are industries, including chemicals, pharmaceuticals, the only company with intensive expertise across automotive, construction, furniture and packaging. the three main engineering fields. And we have a strong track record in integrating this expertise to develop new processes and systems. We are the “people...

Open the catalog to page 2

EX injection molding machines – combining fastest dry cycle times, outstanding precision and cleanliness. KraussMaffei’s EX series is an all-electric machine concept. Key characteristics are high performance, high precision and the fastest dry cycle times in the industry. Chiefly responsible for delivering the speed and performance is the unique Z toggle – it’s at the heart of the EX machine. Together with a direct-driven electric injection unit, this engineering concept guarantees outstanding precision, ultra-fast responses and absolute cleanliness.

Open the catalog to page 3

TRANSPARENT TECHNOLOGY Meet the machine: take a tour of an EX injection molding machine Unique Z toggle clamp concept for very fast dry cycle times, high precision and uncompromising cleanliness Fully encapsulated clamp elements absolutely greasefree lubrication helps to keep the mold zone clean Electric drives for all machine axes highest efficiency and outstanding precision

Open the catalog to page 4

Proven screws and non-return valves from KraussMaffei’s comprehensive standard range deliver excellent melt quality processing many different materials High-torque direct drive with direct transmission of force for precisely repeatable machine movements Water-cooled motors shared cooling for drives and MC5 control system with 32-bit signal processing and intuitive user interface Generous daylight between tiebars means ample space for big molds inverters for enhanced performance

Open the catalog to page 5

DETAILED PRODUCT INFORMATION The EX clamping concept – unparalleled dynamics KraussMaffei supplies EX injection molding mold movements via a worm gear. Rapid machines in clamp sizes ranging from 50 to movements and ultra-fast clamp force build-up 240 tonnes that set new standards in every way. and release are the result. The kinematics of EX all-electric machines achieve extremely fast the Z toggle therefore deliver a clamp-speed dry cycle times and deliver peak performance. profile that is close to optimal for demolding. EX dry cycle times rank among the fastest on The innovative Z toggle...

Open the catalog to page 6

Thanks to the Z toggle, EX machines offer extreme speed, precision and cleanliness. The Z toggle ensures that clamp movements the tiebars makes even very large molds easy to are precision controlled, even at peak operating install. Furthermore, an extremely sensitive safety speeds. The platens have been designed by the mechanism prolongs mold life while ensuring finite elements method (FEM) so that large and consistently high demolding precision. small molds alike apply force optimally with minimal deformation. Platen deflection has been minimized. The result is a movement profile with very...

Open the catalog to page 7

DETAILED PRODUCT INFORMATION Direct force transmission for extreme precision The injection unit is one of the key factors Peerless precision governing product quality. Its fitness for purpose Machine movements are calculated with is measured in terms of gentle melt preparation high-resolution precision and scanned and consistent shot weights. And these are pre 500 times a second by the MC5 microprocessor cisely the strengths of the EX series. control system. The control cycles are very short thanks to the rapid response of the High-torque direct drive – electric drives. The electric drives...

Open the catalog to page 8

“Ultra” injection units have two connected direct drives that can deliver maximum injection speeds, even for large screw diameters. “Ultra” injection unit – twice the drive for double the performance The “Ultra” injection unit was developed for appli third motor. The unit’s drive system can thus reach cations requiring extremely fast injection. This extraordinary injection speeds – even for large- variant for high-spec injection molding uses two diameter screws. For example, an Ultra unit injects coupled direct drives to exclusively power injection at up to 800 mm/s, without sacrificing...

Open the catalog to page 9

A closer look at the EX machine concept Uncompromising cleanliness – designed in as standard The EX series was engineered from the start they are completely encapsulated, with circulating to be used even in high-spec cleanrooms. The oil lubrication. There is absolutely no risk of the result is a machine that sets new standards for production area being contaminated with lubricant. cleanroom production. Lubricant-free tiebars Less is more: The moving platen is guided not on the tiebars, the Z toggle with only eight pivot points but on four precision linear guides. This means The Z toggle has...

Open the catalog to page 10

Especially in molding for medical and pharmaceutical applications, absolute cleanliness is a must. EX machines have been explicitly engineered for cleanroom production. Injection unit with direct drives and no belts Water cooling significantly reduces waste heat “Less is more” also applies to the injection unit. Conventional systems operate with air-cooled With the drive motors directly coupled, there is drives. By contrast, all main drives on KraussMaffei‘s no need for belts. This completely eliminates a EX machines are water cooled. Water cooling wear part and potential source of...

Open the catalog to page 11

EX series machines are also used for all variants of multicomponent injection molding. EXtra versatility – production cells for every application What makes the EX series unique and yet Multicomponent molding – typically KraussMaffei is the clamp design. The EX platform boasts an extensive range of add-on Whether L, V or Z configuration (piggyback), modules that allow users to adapt the machines anything is possible with the EX series. All the to their own production needs. benefits of all-electric machines – performance, precision and cleanliness – are thus wholly transferable to 2- and...

Open the catalog to page 12All KraussMaffei catalogs and technical brochures

-

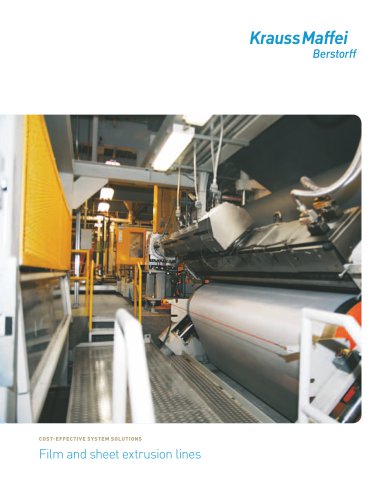

Film and sheet extrusion lines

24 Pages

-

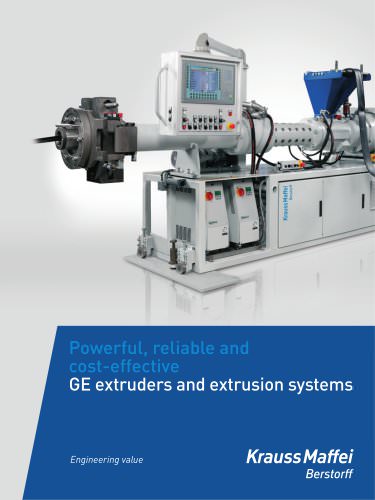

Complete system solutions

16 Pages

-

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

AHEAD 2014

28 Pages

-

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

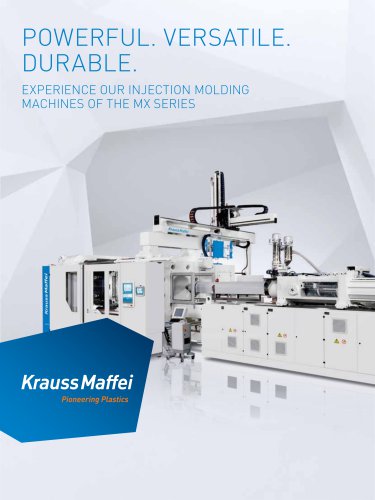

MX injection molding machines

20 Pages

-

Machines in the GX Series

26 Pages