Catalog excerpts

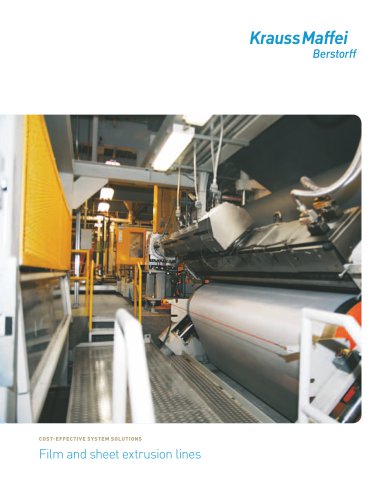

Complete system solutions Cost-effective sheet and film engineering thermoplastics Engineering Value

Open the catalog to page 1

Film and sheet extrusion Facts and figures Facts and figures regarding film and sheet extrusion of PO and engineering thermoplastics Applications Various kinds of PO sheet, mono-extruded Various kinds of PO sheet, coextruded in multiple layers HDPE sheet for shipbuilding Acid tank from PP sheet Plastic sheet in daily use – Sanitary business area Plastic sheet in daily use – White appliance business area Thermoforming film for a variety of uses – Blister packaging business area Thermoforming film for a variety of uses in the cup business area Thermoforming film for a variety of uses in the...

Open the catalog to page 2

Complete system solutions Cost-effective sheet and film extrusion of polyolefins and engineering thermoplastics The importance of polyolefin-based plastics has grown continuously for decades, and the trend is expected to continue. They are used ever more frequently, above all in the sheet extrusion area. The 36D single-screw extruders from KraussMaffei Berstorff are optimally suited for extrusion of sheets from polyolefin, whether compact or foaming. We’ve got what it takes for successful production. Firstly, we supply complete integrated system solutions for a huge range of PO sheet...

Open the catalog to page 3

Everything at a glance Tour of a complete sheet extrusion line Haul-off Single- or double-strand haul-off, pneumatic positioning of the rubber-covered rolls, adjustable speed differential to polishing stack Crosscut saw or router With servo drive Swarf extraction Stacking system with roller table Edge-trim chopper Longitudinal parting saw With servo drive, pneumatic positioning of the cutting blade and the swarf extraction unit

Open the catalog to page 4

Radiant heater Combination of area and point heaters, adjustable zone regulation Polishing stack With high-gloss, chrome-hardened rolls, individual servomotor drives and planetary gears, nip monitoring via electronic sensors, constant temperature profile over the whole width of the roll Swiveling C5 display Fitted to the polishing stack Pressure roll For optimizing flatness (temperature control and drive optional) Screen changer On-board switching cabinet for the downstream equipment Temperature control unit With water or oil as the medium Single-screw extruder KME 150-36 B/PL With...

Open the catalog to page 5

Film and sheet extrusion Setting benchmarks for PO sheet production – with 36D single-screw extruders Many market segments and application areas are turning increasingly to polyolefin sheet: Be one step ahead of the competition with KraussMaffei Berstorff. guarantee the constant pressure required for this process and provide high output at a uniform temperature profile. The extruder can also be operated without a melt pump. Complete system solutions from the world's leading system supplier. KraussMaffei Berstorff has long been a world-leading system supplier of PVC sheet extrusion lines,...

Open the catalog to page 6

Polishing stack with hard-chromed rolls, individually driven via servo motors and planetary gears

Open the catalog to page 7

First encounter Take a tour of the 36D single-screw extruder Off-center feed Avoids turbulence and maximizes output Robust gearbox Long life, lowest maintenance costs and space savings (gearbox and motor form a U)

Open the catalog to page 8

Gravimetric weighing of material Deep-nitrided grooved bush Outstanding cooling performance, lowest cooling water consumption, steady material feed – independent of counterpressure – and self-cleaning Bimetallic barrel Lowest wear rates Barrier screw For thermal and materially homogeneous melts and low melt temperatures. Optimal drive dimensions With DC drive unit (standard) or AC drive unit (optional), air-cooled (standard) or water-cooled (optional

Open the catalog to page 9

C6 central line control system One control system – everything in hand C6 control system – flexible system for open-and closed-loop control and monitoring of an extrusion line With its new, innovative C6 control system, KraussMaffei Berstorff offers fast, direct access at all times to the individual units of an extrusion line, the extruders which work conjointly to produce the product, and to integrated downstream equipment. With its numerous monitoring and control functions, the C6 control system ensures optimal production preparation and transparency throughout the production process,...

Open the catalog to page 10

Polishing stack with temperature control unit and swiveling control display

Open the catalog to page 11

Film and sheet extrusion Best equipped for the markets of the future – exploit lucrative potential with new applications Various types of PO sheet, monoextruded or coextruded in multiple layers

Open the catalog to page 12

No matter how varied and specialized your PO sheet production needs may be, KraussMaffei Berstorff’s 36D single-screw extruders are more than equal to the job. Processing materials for a broad range of products The screws in our 36D single-screw extruder series provide decisive advantages for excellent product quality and high economic viability. With KraussMaffei Berstorff sheet systems, you can process materials for a wide range of products, which above all are used in building containers for water and acid cisterns. HDPE sheet – unbeatable advantages in countless applications HDPE sheet...

Open the catalog to page 13

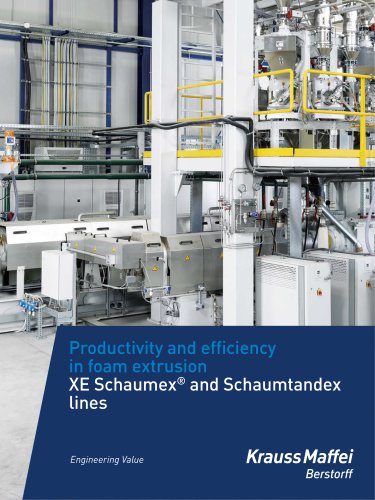

Film and sheet extrusion Further information Further information This might also be of interest to you You can find detailed information on sheet extrusion solutions from KraussMaffei Berstorff in the following brochures: – VC sheet and film P – -PVC pipes and sheet C – xtrusion lines for films and sheets E – E Schaumex and Schaumtandex X systems You can find our brochures and flyers on other topics online at: www.kraussmaffeiberstorff.com. On request, we will also be pleased to send you the information and technical data for our products free of ch

Open the catalog to page 14

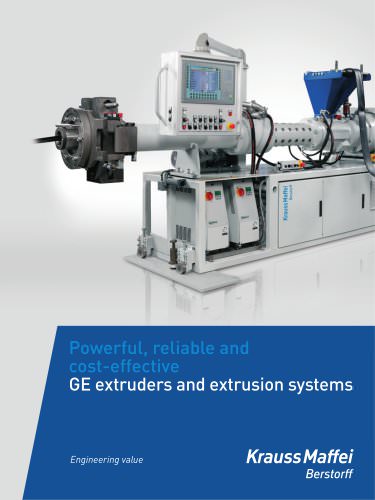

KraussMaffei Berstorff A strong brand in a unique global group Value-proven Extrusion Technology solutions Around the world, KraussMaffei Berstorff stands for reliable and value-proven solutions in Extrusion Technology. These range from using individual extruders for degassing in polymerization, compounding, pipe, profile, film and sheet extrusion, physical foaming and the manufacture of technical rubber articles and intermediates for tire production up to complete extrusion lines. All machines and systems from KraussMaffei Berstorff are custom-configured, for example for the chemical,...

Open the catalog to page 15All KraussMaffei catalogs and technical brochures

-

Film and sheet extrusion lines

24 Pages

-

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

AHEAD 2014

28 Pages

-

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

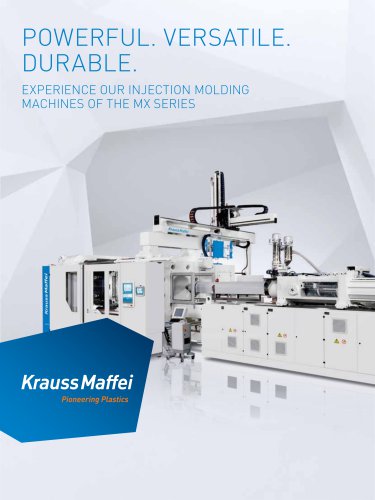

MX injection molding machines

20 Pages

-

Machines in the GX Series

26 Pages