Catalog excerpts

Precise. Productive. Energy efficient. The all-electric AX Series Engineering Passion

Open the catalog to page 1

Machines in the AX Series Facts and figures Facts and figures regarding the all-electric AX Series Application areas Automotive industry Electrical engineering/ electronics industry Consumer goods Medical/pharmaceutical industry Clamping/injection matrix Machine/ clamping force in to Injection units (screw diameter in mm) SP 55

Open the catalog to page 2

The all-electric AX Series The AX machine concept includes a large modular kit for many different applications and is therefore ideally suited for a large number of industries. From 50 to 350 tonnes, the AX Series will always provide you with the right machine combination for your demanding applications. Every AX machine can be precisely equipped from an extensive range of plasticizing units, automation units and options. Highlights of the AX Series at a glance: Precise thanks to: – Direct operating principles – Highly accurate servomotors – Intelligent closed-loop control system Productive...

Open the catalog to page 3

Transparent technology Tour of the all-electric AX injection molding machine Flexible, fully integrated automation Extensive options catalog 5-point double toggle lever with robust mold fixing platens Smooth-running linear guides Barrier-free access

Open the catalog to page 4

High-end plasticizing units Precise drive technology Efficient energy management Intelligent MC5 control system

Open the catalog to page 5

Machines in the AX Series Universal clamping unit The universal AX clamping unit Versatility and efficiency coupled with high precision With clamping forces ranging between 500 and 3500 kN, the AX Series covers a wide range of products. The efficient and highly dynamic 5-point double toggle lever coupled with intelligent servodrive technology ensures maximum productivity and cost-efficiency while also providing optimum mold protection. Stable processes thanks to quick and precise movements Highly dynamic and precise servomotors move to set travel positions for the shutoff or for the ejector...

Open the catalog to page 6

The optimized drive system is synonymous with precise and dynamic clamping movement. Thanks to the wide positioning range of mold height adjustment, large and small molds can normally be used

Open the catalog to page 7

Machines in the AX Series Universal clamping unit The AX features large robust mold fixing platens. The moving platen is broadly supported on linear guides. The tiebars therefore remain free of grease Frictionless production thanks to optimum clamping mechanics The play-free and smooth-running mechanics are a prerequisite for the efficiency, dynamism and precision of the AX clamping units. The kinetically optimized 5-point double toggle lever and the play-free ball screw (with recirculating ball bearings) jointly produce maximum force transmission with high speeds during opening and...

Open the catalog to page 8

Wide opening and barrier-free safety gates for easy accessibility to the mold and ejector Ergonomic concept for easy accessibility and use Wide opening safety gates on the operator's side and non-operator side ensure easy accessibility to the mold and ejector, for example for set-up processes. The safety gates are self-supporting and do not have any interfering crossbars on the housing. This makes every mold change easier, even with a low crane height, and part demolding by a robot is speeded up. In the case of falling parts, it is possible to integrate both billet and sorting chutes along...

Open the catalog to page 9

Grease-free tiebars Changeable mold fixing platens Drive unit for clamping unit Mold height adjustment Precision linear guide Universal clamping concept for clamping forces between 500 and 3500 kN Symmetrical force transmission ensures optimum clamping of the mold The tightly toleranced and totally symmetrical design of the clamping unit produces direct and uniform force exertion on the moving and fixed mold fixing platen. Thanks to the composite structure of the molding fixing platens based on a carrier and adapter plate, forces are evenly distributed when clamping force builds up and are...

Open the catalog to page 10

Every AX machine can be precisely equipped from an extensive options catalog Practical and functional additional fittings for your mold The extensive AX options catalog contains practical solutions and powerful additional functions for your individual applications and mold technologies. Thanks to an additional and mobile hydraulic power pack, core pulls or needle seal nozzles can be directly programmed and controlled via the MC5 control system. Pre-piped connections for cooling water and temperature control circuits are situated close to the mold, thus making every mold connection easier...

Open the catalog to page 11

Machines in the AX Series First-class injection unit The first-class AX injection unit Precise and productive with maximum efficiency In the AX injection unit, the ideal interaction between excellent plasticizing and precise drive technology ensures first-class shot weight constancy. The AX machine reproduces parts with the highest quality and efficiency - shot for shot. High availability and reliability make it the productive leader for every production process. Excellent melt quality for every application KraussMaffei plasticizing units are characterized by excellent melt quality coupled...

Open the catalog to page 12

The impressive features of the AX include its excellent reproducibility and high availability Reproducible processes thanks to built-in precision and dynamism The injection movement is driven by highly precise and dynamic servomotors, and is transmitted directly to the screw via a play-free and directly acting spindle system. Thanks to their extremely dynamic response, the motors regulate the set process parameters of speed, path and pressure in the minimum tolerance range very quickly and precisely. The injection pressure is measured directly in the force flow as an absolute value by means...

Open the catalog to page 13

Machines in the AX Series First-class injection unit Configuration of the AX injection unit from SP 55 to SP 750 / Ø 15 – 55 mm Your advantages: – irst-class shot weight constancy F – igh process reliability H – igh level of productivity H – xcellent melt quality E – ow energy consumption L – igh reliability and availability H – lexible and practical use F

Open the catalog to page 14All KraussMaffei catalogs and technical brochures

-

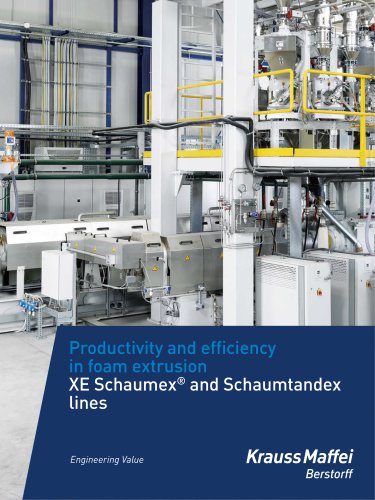

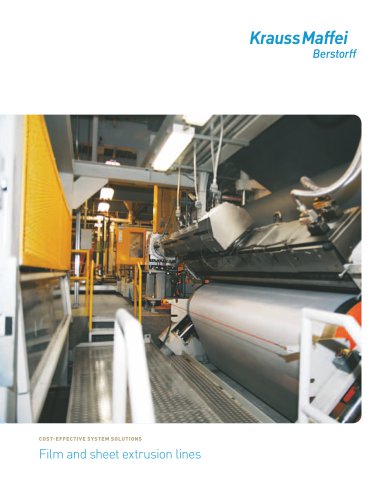

Film and sheet extrusion lines

24 Pages

-

Complete system solutions

16 Pages

-

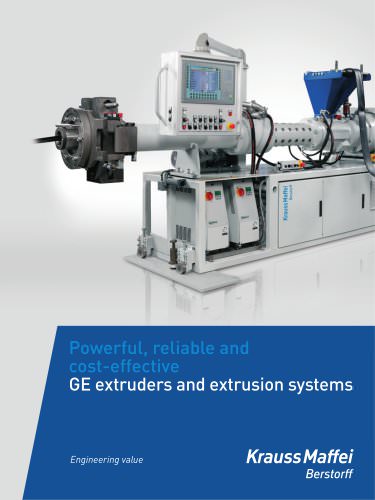

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

AHEAD 2014

28 Pages

-

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

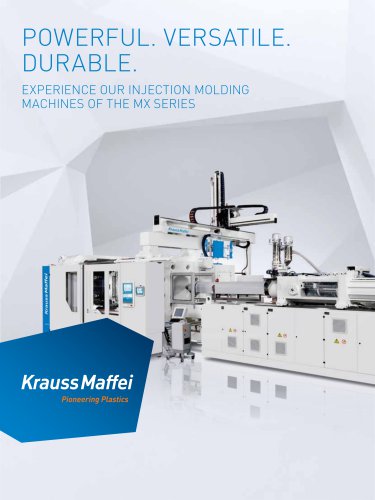

MX injection molding machines

20 Pages

-

Machines in the GX Series

26 Pages