Catalog excerpts

We provide the following: – Energy-efficient production thanks to innovative machine technology – Active wear-resistance on screws and barrels – Flexibility when processing different formulations – Innovative system solutions AHEAD The CUSTOMER Magazine of KraussMaffei berstorff Issue 01.2014 Ahead The customer magazine of KraussMaffei Berstorff Issue 01.2014 From a raw material to an end product Strong technology partnership for the Chinese market On track for NFC – Natural Fiber Composites KraussMaffei Berstorff is a system supplier. We provide complete systems for processing the whole range of natural fiber-reinforced plastics. The mix of natural fibers – wood, hemp, rice husks, flax or similar materials – and polymer is processed in co-rotating or counter-rotating twin-screw extruders to produce composite materials. The composite products such as WPC (Wood Plastic Composites) have excellent properties, including durability and moisture-resistance. Engineering Value

Open the catalog to page 1

KraussMaffei Berstorff CONTENTS Cover story 4 Strong technology partnership for profile extrusion in the Chinese market Brand & markets 8 Recycling compounders: ARTEC and KraussMaffei Berstorff 10 Restructuring of product management 11 Uwe Wagner: New Head of the Rubber Technology Production Area Dear customers, dear readers, Anyone who is looking for manufacturing solutions in the field of extrusion and compounding cannot fail to stumble across the machines and systems of KraussMaffei Berstorff. In 2013, many of you found what you were looking for again – not least of all at the world's...

Open the catalog to page 2

KraussMaffei Berstorff From a raw material to an end product – everything from a single source KraussMaffei Berstorff and Greiner Extrusion equip the first production facilities for environmentally friendly Ecolife® window profiles by Kappes Environment Technology with an innovative overall system concept. 18 With one click KraussMaffei Berstorff develops a new procedure for the production of flooring tiles. 22 On course for growth KraussMaffei Berstorff: Locally produced machines and systems to meet the needs of the Chinese and Asian markets.

Open the catalog to page 3

Cover story Premium-quality end product The ECOLIFE® window profile with a core of wood flour and recycled PO and a premiumquality outer layer of HDPE with an aluminum protective coating.

Open the catalog to page 4

Cover story KraussMaffei Berstorff Strong technology partnership for profile extrusion in the Chinese market KraussMaffei Berstorff and Greiner Extrusion equip the first production facilities for ECOLIFE® window profiles by KET Wood-plastic composites are a promising new way of replacing expensive plastics in part with renewable raw materials. And the WPC innovation prize for an innovative new application of this material combination for window profiles goes to a Chinese company under German management. Text: Annemarie Pabst, Andreas Weseler, Joachim Weber Photos: KraussMaffei Berstorff,...

Open the catalog to page 5

Cover story First, an extremely high throughput of up to 1,500 kg per hour had to be achieved with a modular construction. In addition, this system had to have an even more compact design than all of its predecessors, in order to fit in the space available, including the limited hall height. The self-supporting design of the modules means Kaiteya only needs a lightweight hall, whose procurement costs are significantly lower than those of a conventional production hall. The fully automatic modular system for Bengbu covers the entire process from raw material supply to bagging of the finished...

Open the catalog to page 6

Cover story KraussMaffei Berstorff The extruder has two venting devices to extract humidity, which can be as much as 12 percent. In addition to atmospheric venting, a water ring pump ensures that the high volume of steam is extracted. The 6-D long venting port with special WPC inserts guarantees efficient and safe humidity extraction together with the high free screw volume. From the extruder, the compound melt is transferred to a melt pump that routes it into the underwater pelletizing unit with gentle pressure build-up and without a temperature increase. The underwater pelletizing unit is...

Open the catalog to page 7

Brand & markets Brand & markets Recycling and compounding under heat with Edelweiss system technology Artec and KraussMaffei Berstorff break down efficiency barriers Two leading plastic systems engineering companies have decided to pool their expertise. In September 2013, the Austrian recycling specialist ARTEC machinery and the German extruder manufacturer KraussMaffei Berstorff decided to cooperate in the field of recycling compounders. Text: Andreas Weseler Photos: KraussMaffei Berstorff, Artec machinery and in hand, Artec and KraussMaffei Berstorff wish to break down the efficiency...

Open the catalog to page 8

Brand & markets KraussMaffei Berstorff Trend-setting The new ARTEC recycling technology, here based on the example of the ARTEC MODUL 500 system, was designed with the focus on modularity, ergonomics, user-friendliness and, last but not least, energy efficiency. Recycling competence from ARTEC KraussMaffei’s contribution to the partnership is its experience in the compounding of recycling materials, while ARTEC contributes its processing technology comprising cutting compressors with dehumidi fication function, single-screw extruders with venting technology and individually coordinated...

Open the catalog to page 9

Brand & markets Peter Oswad, Head of Product Management at KraussMaffei Berstorff, Munich Restructuring of product management Innovation drivers all under one roof As a result of structural reorganization, Product Management for Extrusion Technology at the Munich site has become stronger and more forward-looking. Since October 1, 2013, Peter Oswald has been managing the team of experts that supports the pipe, sheet and profile extrusion products. Text: Annemarie Pabst Photos: Harald Mehnert “The restructuring of Product Management with Peter Oswald and his employees Annette Beierling,...

Open the catalog to page 10All KraussMaffei catalogs and technical brochures

-

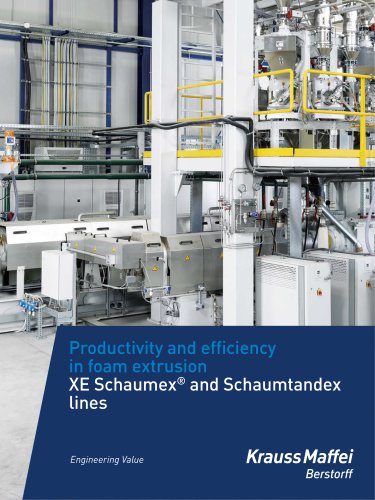

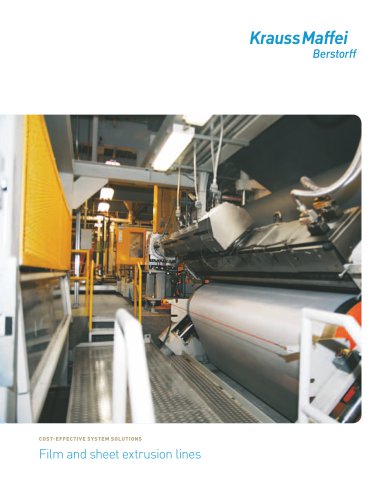

Film and sheet extrusion lines

24 Pages

-

Complete system solutions

16 Pages

-

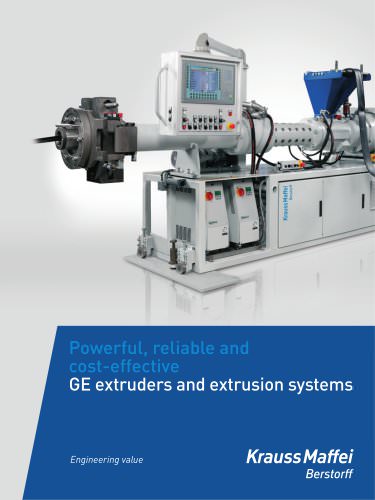

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

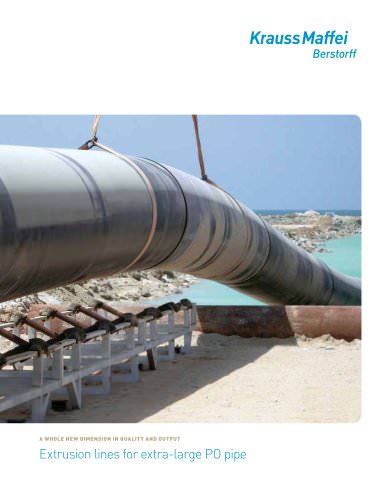

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

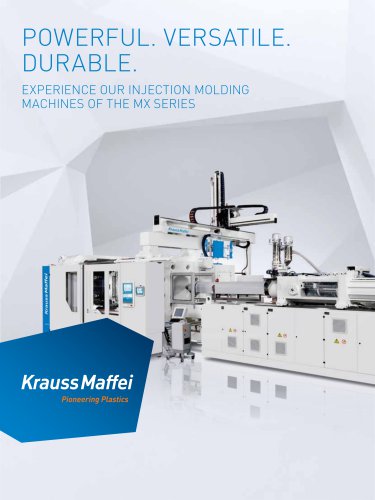

MX injection molding machines

20 Pages

-

Machines in the GX Series

26 Pages