Catalog excerpts

STRONG ON PERFORMANCE, VERSATILE AND HIGHLY COMPETITIVE ON COST 36D twin-screw extruders - pipe extrusion series

Open the catalog to page 1

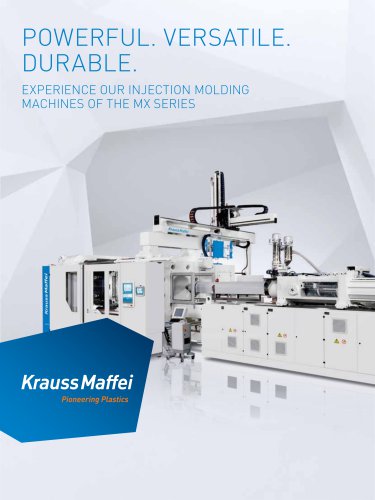

IN PARTNERSHIP WITH INDUSTRY KraussMaffei is a premium partner for the plastics and rubber processing industries Automotive White Goods Construction Life Sciences Electrical/Electronics Whatever you aim to achieve in plastics or rubber processing, KraussMaffei is your partner. We are the only company with intensive expertise across the three main engineering fields. And we have a strong track record in integrating this expertise to develop new processes and systems. Our Injection Molding Machinery Division supplies machinery and systems from 35 to 4,000 tonnes for standard applications and...

Open the catalog to page 2

High throughput and top quality with Our parallel 36D series twin-screw extruders have been specifically engineered for PVC processing. Our aim is to ensure you a good return on your investment through a combination of high throughput and top product quality. The platform for our wide product range is a modular machine concept that enables customized production solutions for cost- competitive, high-performance pipe extrusion. Look at the striking advantages. The specially designed screw concept enables very gentle and homogenous plasticizing. Long processing units ensure stable processes...

Open the catalog to page 3

TRANSPARENT TECHNOLOGY take a tour of a 36D twin-screw extruder Gravimetric weighing High-torque gear system drive technology Gear lubricating unit for

Open the catalog to page 4

Suction conveyor Material hopper Blowing agent metering Feed throat 36D processing unit with molybdenum- plated screws and deep-nitrided, air-cooled barrel Vacuum degassing with a sturdy waste pipe and quick connection Vacuum degassing unit with double solids separator p Diagram showing a 36D extruder equipped for foamcore pipe extrusion

Open the catalog to page 5

DESIGN BASICS 36D twin-screw extruders with an optimized screw concept for ultra-flexible processing The 36D twin-screw extruders with their HPG (High Performance Geometry) screw concept are ideal in every way for producing U-PVC and M-PVC pipe, foamcore PVC pipe and PVC-O pipe. High Performance Geometry (HPG) The HPG screw design incorporates an effective preheating length with an extended output and mixing zone. The whole length of 36 L/D can be used for processing the PVC compound. This results in significant benefits for processors. The long effective preheating zone means a high degree...

Open the catalog to page 6

CUTTING MATERIAL COSTS PVC foamcore pipe - produced on Raw material costs can account for up to 90% of the manufacturing cost of plastic pipe. Material costs can be slashed by producing PVC foamcore pipe on 36D twin-screw extruders combined with the foamcore pipeheads developed by KraussMaffei Berstorff. The 36D twin-screw extruders deliver premium product quality. They can be used as main extruders or as coextruders. Foaming the middle layer of the 3-layer pipe reduces its density to as low as 0.6 kilograms per cubic decimeter. This reduces the total density of the composite pipe by up to...

Open the catalog to page 7

DETAILED PRODUCT INFORMATION Our modular extruder concept - the recipe for success with cost-effective, customer- specific solutions Like all the extruders built by KraussMaffei Berstorff, the twin-screw extruders in the 36D series are engineered to an intelligent modular design. Starting with a universal machine frame and a standard barrel, KraussMaffei Berstorff can supply customized extruders closely matched to customer requirements. A closed-loop controlled metering unit with a conveying spiral ensures constant specific melt throughput, even with different formulations. The metering...

Open the catalog to page 8

DETAILED PRODUCT INFORMATION Lower material consumption and constant product quality - with twin-screw extruders Big savings in pipe manufacturing costs through the use of fillers or by foaming the core layer cannot be allowed to impact on pipe quality. Special metering unit for high filler content In the fiercely competitive PVC pipe market, where producers are face constantly increasing pressure on prices, there is a strong trend towards taking filler content as high as possible. This is especially the case for waste water pipe, but also increasingly for pressure pipe. Producers not only...

Open the catalog to page 9

DETAILED PRODUCT INFORMATION monitoring systems in the industry Centralized control of the extrusion line Meeting tough specifications for product quality and output demands a stable, reliable production process. This is where the C5 control system scores. As one of the most advanced systems in the industry, it offers dependable technology and intelligent functions for centralized control and monitoring of extrusion lines. For the operator, the C5 ensures optimal set-up and start-up, and a clear, consistent overview of the pro- duction process. Monitoring and control is facilitated by...

Open the catalog to page 10

CUSTOMER BENEFITS AND APPLICATIONS pipe extrusion series The parallel twin-screw extruders in our 36D pipe extrusion series are specially engineered for processing PVC dryblend and highly-filled Your benefits at a glance: ■ Low maintenance thanks to internal screw temperature control and air-cooled barrels ■ Optimal control of the melt temperature over the whole output range ■ Reliable degassing - also for highly filled compounds ■ Higher pressure build-up thanks to longer metering zone ■ High output and perfect product quality ■ More flexibility with a wide processing window for different...

Open the catalog to page 11

SERVICE WORLDWIDE Service, support and spare parts - when you need them, where you need them Rely on us for a fast and competent response to all your service needs anywhere in the world. Whatever you need - from troubleshooting and training to spares or repairs - we're on the job. We're dedicated to supplying service quality on a par with the outstanding quality of our machines and systems. We offer far more than spare parts and hotlines. We'll work with you to choose the best and most cost-effective solution for your operation. We'll help you test new applications and we'll plan customized...

Open the catalog to page 12

Worldwide hotline Email: service-ext.ukHkraussmaffei.com Krauss Maffei Corporation Email: service-ext.usHkraussmaffei.com Krauss Maffei de México Mexico City, México Krauss Maffei do Brasil Ltda KraussMaffei Technologies GmbH Munich, Germany Customer Service Phone: +49 89 8899-2273 (electrical systems] Phone: +49 89 8899-4380 (mechanical systems] Application Engineering Abbiategrasso, Italy Moscow, Russia KraussMaffei Technologies Pune, India Krauss-Maffei Extrusion Jiaxing City, China international service or spare parts teams by post, use this address: Extrusion Technology Service...

Open the catalog to page 13All KraussMaffei catalogs and technical brochures

-

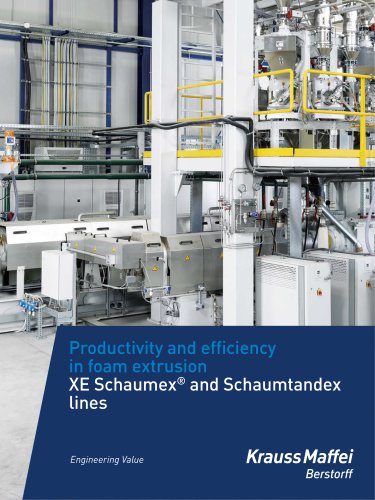

Film and sheet extrusion lines

24 Pages

-

Complete system solutions

16 Pages

-

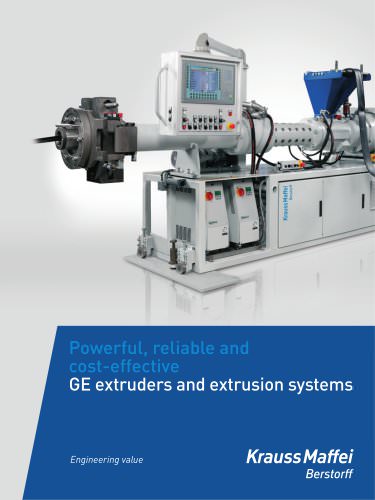

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

AHEAD 2014

28 Pages

-

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

MX injection molding machines

20 Pages

-

Machines in the GX Series

26 Pages