Catalog excerpts

I Increased flexibility and greater 1 cost-efficiency in profile extrusion profile series Engineering Value

Open the catalog to page 1

32D profile series Facts and figures Facts and figures regarding the 32D twin-screw extruder profile series Applications Cable ducts Window profiles in core technology, extruded with regrinds Foam profiles Other applications Coextruded window main profiles Window profiles – Secondary chamber/multi-chamber profiles – Gutters – Door/shutter systems – Window sills – Technical profiles – NFC/WPC profiles – Siding solutions – Special customer-specific solutions Technical data and dimensions of the 32D twin-screw extruder series Motor power output [kW] Screw heating/cooling Length incl. adapter...

Open the catalog to page 2

32D twin-screw extruder profile series Increased flexibility and greater cost-efficiency in profile extrusion In the area of profile extrusion the market is placing increasingly higher demands on production: Excellent quality, maximum flexibility and increased cost-efficiency. The 32D twin-screw extruder series from KraussMaffei Berstorff satisfies all conditions for optimum profile extrusion. The highlights at a glance: – uperb profile quality coupled with high S production flexibility – mproved melt homogeneity thanks to a I long processing unit – xtension of the processing window thanks...

Open the catalog to page 3

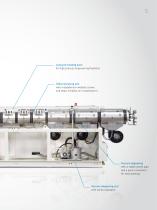

Impressive encounter Take a tour of the 32D twin-screw extruder for profile extrusion Rectangular filling opening allows optimum screw filling Standard dosing unit for processing many different materials Robust gearbox ensures low maintenance costs and a long service life Ideally dimensioned drive concept

Open the catalog to page 4

Long pre-heating zone for high process engineering flexibility 32D processing unit with molybdenum-welded screws and deep-nitrated, air-cooled barrel Vacuum degassing with a stable waste pipe and a quick connection for easy cleaning Vacuum degassing unit with solids separator

Open the catalog to page 5

32D profile series: Detailed product information Top-class results in profile extrusion More flexibility thanks to technically perfectly coordinated components All parallel KraussMaffei Berstorff twin-screw extruders for profile production are equipped with processing units in the length 32D. The screw concept The screw concept of the 32D twin-screw extruder series is characterized, in particular, by three advantages: It optimizes material processing, improves melt homogeneity and permits a very wide processing window when processing many different materials. Focus on pre-heating zone As...

Open the catalog to page 6

High-performance extrusion – KraussMaffei Berstorff has the perfect solution for every task Power distribution to two drive trains each with 50 % Power output each with 50 % Irrespective of the extrusion solution which you select in your production, KraussMaffei Berstorff has a technically impressive and highly economical system for this purpose. Powerful gearbox The 32D twin-screw extruder series is characterized by high output rates. An extremely powerful gearbox is required to safely attain the high screw torques. We have used precisely this: The gearbox has a compact, robust and...

Open the catalog to page 7

C6 central line control system One control system – everything in hand C6 control system – flexible system for open-and closed-loop control and monitoring of an extrusion line With its new, innovative C6 control system, KraussMaffei Berstorff offers fast, direct access at all times to the individual units of an extrusion line, the extruders which work conjointly to produce the product, and to integrated downstream equipment. With its numerous monitoring and control functions, the C6 control system ensures optimal production preparation and transparency throughout the production process,...

Open the catalog to page 8

Extrusion or coextrusion The 32D twin-screw series is very impressive We have the right answers to all questions in connection with profile extrusion. Maximum flexibility The 32D series features maximum flexibility in processing different formulations and materials, changing a formulation, using different molds and easy handling of the machine. Constant quality The 32D series provides over a defined performance range constant product quality with homogeneous profile surfaces, smooth inner surfaces even at a high output rate, minimum weight meter fluctuations and high mechanical strength....

Open the catalog to page 9

32D Profile extrusion Further information Further information This might also be of interest to you You can find further information on profile extrusion solutions from KraussMaffei Berstorff in the following brochures: – rofile extrusion solutions: P Powerful and cost-effective for all application areas – onical twin-screw extruders for profile C production – ystem solutions for processing natural S fiber-reinforced plastics You can find our brochures and flyers on other topics online at: www.kraussmaffeiberstorff.com. On request, we will also be pleased to send you the information and...

Open the catalog to page 10

KraussMaffei Berstorff A strong brand in a unique global group Value-proven Extrusion Technology solutions Around the world, KraussMaffei Berstorff stands for reliable and value-proven solutions in Extrusion Technology. These range from using individual extruders for degassing in polymerization, compounding, pipe, profile, film and sheet extrusion, physical foaming and the manufacture of technical rubber articles and intermediates for tire production up to complete extrusion lines. All machines and systems from KraussMaffei Berstorff are custom-configured, for example for the chemical,...

Open the catalog to page 11

Increased flexibility and greater cost-efficiency in profile extrusion: The 32D twin-screw extruder series The series is also ideally designed to cope with something which the market now increasingly expects and demands from production, i.e. flexible profile extrusion for maximum cost-efficiency. 1.0 WE 2nd edition 01/2014 EXT 003 BR 10/2012 EN ··· Subject to technical changes ··· Printed in the Federal Republic of Germany During production, it combines superb profile quality with high production flexibility and excellent cost-efficiency. The long processing unit of the twin-screw extruders...

Open the catalog to page 12All KraussMaffei catalogs and technical brochures

-

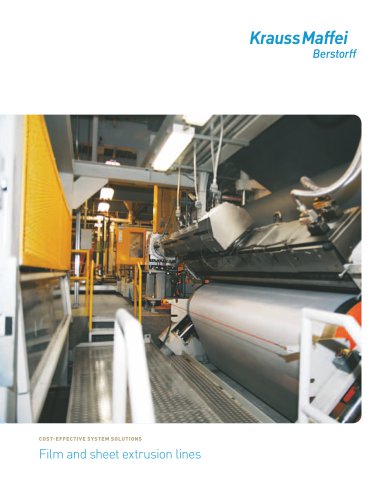

Film and sheet extrusion lines

24 Pages

-

Complete system solutions

16 Pages

-

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

AHEAD 2014

28 Pages

-

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

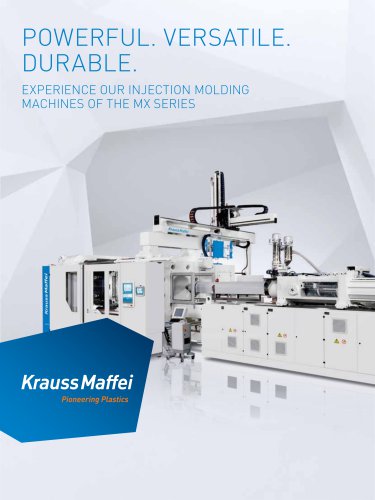

MX injection molding machines

20 Pages

-

Machines in the GX Series

26 Pages