Catalog excerpts

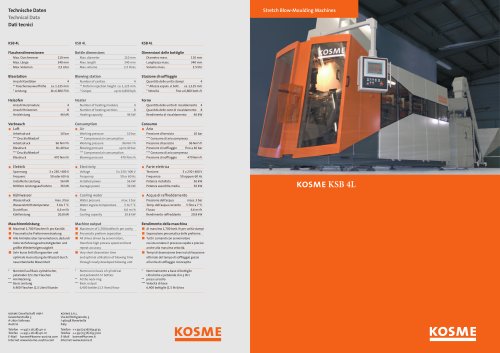

Stretch Blow Moulding Packaging Filling Labelling Conveying KOSME KSB R KOSME KSB R ProShape KOSME KSB RG

Open the catalog to page 1

The KSB R series A high output per blowing station even for high output levels – that is a main characteristic of the KOSME KSB rotary machines. With these machines fillers of smaller production batches can produce PET bottles in a broad range of sizes quickly and with a high output level. The KSB R series comprises compact, easily accessible machine models which offer great ease of use in daily operation. These reliable, operator-friendly machines provide you with a high degree of flexibility and an optimal price-performance ratio. The machines of the KSB R series produce bottles with a...

Open the catalog to page 2

System advantages Precise, high-performance bottle production Fast conversion in case of a product change-over Economic energy and compressed-air consumption Economic in investment and production costs Easily accessible machine design Air recycling Preform mounts with screening plates KOSME Stretch Blow Moulding | The KSB R series | System advantages

Open the catalog to page 3

The machines of the KSB R series produce top-quality PET bottles – and are economical in their energy and air consumption. For example, the module oven contributes to energy savings, which meet the most demanding standards with regard to cooling and preform settings. Energy efficiency can also be achieved with the optional air recycling system: The entire requirement for low-pressure air of the stretch blow moulding process is recovered from the main blowing air. As a result, the entire pneumatic system on the blowing wheel and the pre-blowing process when stretching the preforms is...

Open the catalog to page 4

Heating area Bottle transfer KOSME Stretch Blow Moulding | The KSB R series | Method of operation

Open the catalog to page 5

Preform feed unit The preforms deposited in the hopper are routed into the roller orientor via a vertical conveyor. There the preforms are aligned hanging and routed into the feed ramp. Heating process The infeed starwheel picks up the preforms and transfers them to the preform conveyor belt. Now they run through the heating system while rotating continually. At the end of the heating section, an infrared camera scans the temperature of each preform and transfers this to the controller. This enables a temperature variance comparison and – if necessary – an automatic correction of the...

Open the catalog to page 6

Patented heating module Preform feed rail Stretch Blow Moulding | The KSB R series | Assemblies in detail

Open the catalog to page 7

Heating system Depending on size, 6 to 12 heaters with 8 or 9 radiators Patented adjustment system for exact positioning of infrared lamps from outside with oven closed for optimal heating of preforms Extremely energy-saving heating system with individual control of all radiators Solid transport chain with integrated preform gripper Blow-moulding station Circulation concept with mould hangers made of special alloy with low weight – reduced centrifugal forces and wear Patented, fast-closing locking system for maximum production time Installation of blowing valve directly on blowing nozzle –...

Open the catalog to page 8

KSB 4RG and 6RG – specifically for large containers Machines with four or six blowing stations for manufacturing large containers Flexible machine concept for a broad range of products Production range for containers from 0.5 to 6.0 litres Transfer clamp for large containers KOSME Stretch Blow Moulding | The KSB R series | KSB 4RG and 6RG – specifically for large containers

Open the catalog to page 9

Transfer from infeed starwheel to conveyor Heating modules Serve many different markets with one machine concept: The KSB 4RG and 6RG product ranges consist of the production of large containers and the classic line of containers in small formats. With the greater pitch of the lashing belt and the larger dimensioning of the blowing stations, all variation options are possible. With the greater pitch of the machines and the adjusted speed for the tempering of the preforms, outputs of 5,000 to 7,500 containers/h are achieved. Bottle output KOSME Stretch Blow Moulding | The KSB R series | KSB...

Open the catalog to page 10

ProShape ‒ selective preform tempering Blow-moulding station KOSME Stretch Blow Moulding | The KSB R series | ProShape ‒ selective preform tempering

Open the catalog to page 11

What can ProShape do? ProShape is a module for selective preform tempering. It enables you to produce oval and asymmetrical PET containers on a KSB R ProShape stretch blow moulder. This is how ProShape works: First the preform is heated evenly in the oven. Then a transfer starwheel transfers it to the ProShape module At the ProShape module, water-cooled aluminium plates reduce the preform’s temperature on precisely defined areas. This way, the preform obtains an individual temperature profile which is tailored exactly to the blowing process and the final bottle shape. After a short...

Open the catalog to page 12

ProShape ‒ your advantages High output Precise tempering for perfectly shaped bottles Enables considerable reduction in material used Round and oval on one machine ProShape module KOSME Stretch Blow Moulding | The KSB R series | ProShape ‒ your advantages

Open the catalog to page 13

High output High speeds are no problem for ProShape: The process enables station outputs of up to 2,000 containers/h. Precise tempering for perfectly shaped bottles The ProShape process operates extremely precisely and allows only extremely small tolerances. This way, each preform obtains a precise temperature prole with exactly dened temperature zones. The result is precisely shaped bottles. Material savings ProShape also makes lightweighting possible for oval and asymmetrical containers, as thick and thin-walled areas can be located very close together, enabling stability with low weight....

Open the catalog to page 14

Technical data * bottle sizes > 5.0 l subject to technical verification by KOSME. KOSME Stretch Blow Moulding | The KSB R series | Technical data

Open the catalog to page 15

Always at your side Extensive consultation on bottle design with design suggestions Precision mould construction Fast delivery of spare and wear parts Support by experienced specialists during commissioning Need-oriented training programme Remote diagnosis and remote support via VPN connection to KOSME Service Center Available worldwide: KOSME service technicians KOSME Stretch Blow Moulding | The KSB R series | Always at your side

Open the catalog to page 16All Kosme catalogs and technical brochures

-

KOSME Synchroblock

12 Pages

-

KOSME KSB Linear

15 Pages

-

FLEXA

8 Pages

-

ULTRACOL

8 Pages

-

UNICOL

8 Pages

-

SENSICOL

8 Pages

-

WEIGHFILL

8 Pages

-

PRIMAFILL

8 Pages

-

BARIFILL

8 Pages

Archived catalogs

-

cold glue labeler Extra

3 Pages

-

filling catalog

16 Pages

-

bottle liquid filler

12 Pages