Catalog excerpts

Stretch Blow Moulding Packaging Filling Labelling Conveying

Open the catalog to page 1

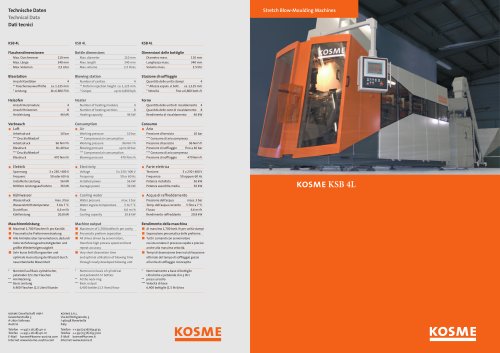

The KSB L series The KSB 2XL and KSB 4L are KOSME’s next-generation linear stretch blowmoulders. KOSME has an impressive track record in the production of many different container and bottle types, and this expertise has been channelled into the design of the linear PET blow-moulders. Each and every detail enhances the reliability, ease of use and flexibility of these machines which offer an optimal priceperformance ratio as a “standard feature”. The KSB 2XL produces containers in the 0.5 – 12.0 litre range. The KSB 4L is designed for container sizes between 0.1 and 3.0 litres. The machines...

Open the catalog to page 2

Preform infeed Blow-moulding station Large range of containers KOSME Stretch Blow Moulding | The KSB L series

Open the catalog to page 3

Outstanding features Top-quality bottles Energy efficient Precision bottle production Quick semiautomatic mould change Air recycling User-friendly operation KOSME Stretch Blow Moulding | The KSB L series | Outstanding features

Open the catalog to page 4

The KSB L produces top-quality PET bottles and keeps energy and air consumption to a minimum. The modular oven is one of the energy-saving features. The cooling subsystem and preform settings on the oven meet standards which are second to none. The optional air recycling system further enhances energy efficiency. The air for the entire low-pressure supply on the KSB L series is recovered from the high-pressure air system. The complete pneumatic system and the pre-blowing step during the preform stretching operation run on recycled high-pressure air. Transfer via infeed starwheel With air...

Open the catalog to page 5

Base mould and preform mould for large containers Bottle discharge from the blow-moulding station KOSME Stretch Blow Moulding | The KSB L series | Method of operation

Open the catalog to page 6

Preform feed Blow-moulding operation An elevator belt moves the preforms from the hopper to the roller orienter where the preforms are vertically suspended and transferred to the infeed ramp. Grippers insert the preforms into the open moulds. Linear servo drives close the moulds which are then mechanically locked. Heating process Depending on the type of preform, the preform is sealed at the neck ring or neck finish. The infeed starwheel transfers the preforms to the preform belt conveyor. The preforms rotate continuously as they pass through the heating system. An infrared camera at the...

Open the catalog to page 7

Blow-moulding station discharge area Bottles exiting the station after blow-moulding KOSME Stretch Blow Moulding | The KSB L series | The major subsystems

Open the catalog to page 8

Heating system Heaters with 8 or 9 heating lamps each Patented adjustment system for precise positioning of the heating lamps Sturdy transport chain with built-in preform gripper Very energy-efficient heating system Blow-moulding station Linear design ensures long service life and low wear Fast-acting locking system Blower valve block with optional air recycling to reduce air consumption Quick-change system for the moulds Moulds from the rotary KOSME and KRONES machines can be used on the KSB 4L Preform feed and bottle discharge Preform and bottle transfer using neck handling on one level...

Open the catalog to page 9

KSB 4L PH Top-class oval containers Built-in preferential heating module Production of reduced-weight containers with a distinctly oval shape The use of lower-weight preform grades cuts cost Highly individualized oval container shapes KOSME Stretch Blow Moulding | The KSB L series | KSB 4L PH Top-class oval containers

Open the catalog to page 10

The grippers: can be replaced in no time Preferential heating module On the KSB 4L PH, a special heating module is installed after the standard heaters. The preforms move through this zone without rotating, and the two opposite sides of the preforms are intentionally exposed to additional heat. Using this temperature profile, reducedweight containers with a distinctly oval shape can be produced, because the moulding characteristics of the material are optimal during the blow-moulding process. The heaters: top performance from a small package KOSME Stretch Blow Moulding | The KSB L series |...

Open the catalog to page 11

Technical data KOSME Stretch Blow Moulding | The KSB L series | Technical data

Open the catalog to page 12

Always at your side Comprehensive bottle design advisory service including design recommendations Precision mould making Fast delivery of spare and high-wear parts Team of specialists to provide support during the startup phase Needs-based training Remote diagnostics and support via modem link to the KOSME Service Centre (analogue, ISDN or GSM network) KOSME service engineers available worldwide KOSME Stretch Blow Moulding | The KSB L series | Always at your side

Open the catalog to page 13

Product changeover using the Easy-Click system Preform transfer Air/media panel KOSME Stretch Blow Moulding | The KSB L series | Always at your side

Open the catalog to page 14

KOSME Gesellschaft mbH Gewerbestraße 3 2601 Sollenau Austria Phone +43 2628 4110 Fax +43 2628 411111 E-mail kosme@kosme-austria.com Internet www.kosme.it Phone +39 0376 751011 Fax +39 0376 751012 E-mail kosme@kosme.it Internet www.kosme.it Via dell’Artigianato, 5 46048 Roverbella Italy Subject to technical changes · 09/13 Stretch Blow Moulding Packaging Filling Labelling Conveying

Open the catalog to page 15All Kosme catalogs and technical brochures

-

KOSME Synchroblock

12 Pages

-

FLEXA

8 Pages

-

ULTRACOL

8 Pages

-

UNICOL

8 Pages

-

SENSICOL

8 Pages

-

WEIGHFILL

8 Pages

-

PRIMAFILL

8 Pages

-

BARIFILL

8 Pages

Archived catalogs

-

cold glue labeler Extra

3 Pages

-

filling catalog

16 Pages

-

bottle liquid filler

12 Pages