Catalog excerpts

Filling The Isoblock G filling system for beer >

Open the catalog to page 1

Bottling beer demands meticu-lously coordinated functional efficacy. Product-friendly handling, worksteps precisely matched to the product and the bottle involved, plus a high standard of hygiene, are keywords of perceived importance in any brew-ery. With the Isoblock G filler, offers a filling system precisely tailored to the requirements of a mid-tier brewer.The compactly dimensioned filler unit is convenient to install even in confined spaces, and can be easily integrated into existing structures. > The filling operation takes place along the vent tube the beer is passed over the...

Open the catalog to page 2

Filling systems for beer | >

Open the catalog to page 3

| Filling systems for beer >

Open the catalog to page 4

Not too much and not too little an apposite summary of the require-ments that a filler for the lower output range has to meet. Not too much in terms of technical options that are seldom actually used, and not too little in terms of user-friendly features required for operating the machine and producing beers of maximised quality in small batches.The Isoblock G translates this philosophy into engineered reality: With flexible interfacing to closing systems for crowns or roll-on closures, or a container orienting function for closing swing-stop- pers, the filler can be equipped to handle any...

Open the catalog to page 5

| Filling systems for beer >

Open the catalog to page 6

The high-pressure injector displaces the air remaining in the bottleneck after the filling operation.CIP cups on the filling valves enable the system to be cleaned in recirculation mode.Cross-sectional view of the filling valve The touch-screen monitor provides an imme-diate overview of all the fillers functions. The isobarometric filling systemIsoblock G is a level-controlled fillingsystem that operates on the counterpressure principle and is intended for carbonated beverages. The fillingsteps have been precisely designed for filling beer, and assure the high quality of speciality beers....

Open the catalog to page 7

Isoblock G with a closure chute for handling crowns Orientation and positioning tunnelfor swing-stopper bottles | Filling systems for beer >

Open the catalog to page 8

Cap feed for roll-on capsEasily accessible cap chutesCustomised systems for special-ity breweries often with swing-stopper handling Orientation starwheel for swing-stopper bottles Cappers Regional breweries with a relatively small output often use swing-stopper bottles. The newly conceived orienta-tion starwheel reduces the operator workload for manual capping. After being filled, the bottle is rotated around its own axis in the discharge starwheel. The swing stopper is lowered under cam control, and held in the desired position. The bottle does not continue to turn , but is passed in this...

Open the catalog to page 9

All operator control steps are handled at the touch-screen monitor.Construction featur-ing steel and stain-less steel means opti-mum cleanability. | Filling systems for beer >

Open the catalog to page 10

With all parts coming into contact with the product constructed of stainless steel, the filler meets the toughest of requirements for a brewerys daily operations. The central control panel with its touch-screen monitor supplies all the information needed for ongo-ing operation. For changing over to different bottles and coping with new additions to the range, the handling parts can be retrofitted in a supplementary delivery, to suit the filler pitch involved and the bottle sizes desired. > Easily accessible valve design is a basic principle of the Isoblock G Smooth surfaces permit effective...

Open the catalog to page 11

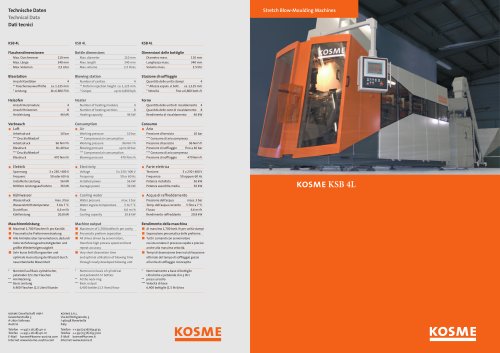

s.r.l.Via dellArtigianato, RoverbellaItalyTelephone + Telefax + Email kosme@kosme.itInternet www.kosme.it >

Open the catalog to page 12All Kosme catalogs and technical brochures

-

KOSME Synchroblock

12 Pages

-

KOSME KSB Linear

15 Pages

-

FLEXA

8 Pages

-

ULTRACOL

8 Pages

-

UNICOL

8 Pages

-

SENSICOL

8 Pages

-

WEIGHFILL

8 Pages

-

PRIMAFILL

8 Pages

-

BARIFILL

8 Pages

Archived catalogs

-

cold glue labeler Extra

3 Pages

-

filling catalog

16 Pages