Catalog excerpts

Product Catalogue Flexible conduit systems, cable glands & accessories for hazardous areas

Open the catalog to page 1

Flexible conduit systems, cable glands & accessories for hazardous areas 1 Flexible conduit systems Cable glands Thread convertors, stopping plugs & accessories Index & useful information

Open the catalog to page 3

Introduction Low voltage products for hazardous areas Oil & Gas - Upstream applications Oil & Gas - Midstream applications Oil & Gas - Downstream applications Food & Beverage applications Chemical & Pharmaceutical applications Standards, Zone Definitions & Product Markings World standards & what they mean 1/12 Zone definitions - Onshore gases & vapours 1/14 Zone definitions - Offshore gases & vapours 1/16 Zone definitions - Dust 1/17 Product marking guide 1/18 Index of ingress protection 1/20 Kopex-Ex Product Catalogue | LIT-166GBR 04/15

Open the catalog to page 5

Kopex-Ex Product Catalogue | LIT-166GBR 04/15

Open the catalog to page 6

Introduction Low voltage products for hazardous areas At ABB, our focus is on improving your business performance by providing practical, reliable electrical products & services. To connect & protect for life. To solve everyday problems in the area’s of Wire & Cable Management, Cable Protection, Power Connection & Control and Safety. Our extensive engineering, supply chain management and technical sales support teams are committed to understanding everything that impacts your ability to accomplish your business objectives by reducing your total cost of ownership. Beyond high performance...

Open the catalog to page 7

Introduction Oil & Gas applications - Upstream applications 1 1 Upstream applications | 2 Midstream applications | 3 Downstream applications The oil and gas market is split into three sectors Upstream, Midstream & Downstream. Upstream consists of Exploration and production. Midstream relates to the transportation, storage and partial processing of crude oil and gas from the wellheads to the refining plants. This brings another set of challenges to overcome. The term downstream relates to the processing and delivery of finished carbon related product to the end-user. Upstream applications...

Open the catalog to page 8

Onshore applications can also be split into exploration and production. Single onshore wells may produce as little as a few barrels per day but networking of onshore wells can result in production of milliions of barrels per day. This brings with it a whole new series of challenges to be overcome. Firstly, the drilling rigs tend to be mobile with motors and pumps often mounted on skids for easy transportation. This can lead to issues of connectivity for which Thomas and Betts has a range of thread converters in a variety of materials, many meeting world standards, ready to resolve the...

Open the catalog to page 9

Introduction Oil & Gas - Midstream applications 1 Midstream relates to the transportation, storage and partial processing of crude oil and gas from the wellheads to the refining plants. This brings a different set of challenges to overcome. This all relates to the fact that what is pumped out of the well is not pure and often contains a mixture of oil, gas, water and often sand which firstly need to be separated off from each other before being shipped or piped to a storage facility. This can be done in a variety of ways depending on the typeof oil or gas that the well is pumping and can...

Open the catalog to page 10

This is also the point when all metering needs to take place to calculate invoices and taxes today. The amount of oil produced is shapely measures, also the density, viscosity, pressure, temperature, and in the case of gas, the amount of water vapour is also measured. Oil is often pumped directly to the oil refinery which is where the down stream operation starts but often needs to go through a series of pumps to get the required pressure. With the Kopex-Ex range of products, ABB can offer a range of products and services to meet the demands of midstream oil and gas markets. The Kopex-Ex...

Open the catalog to page 11

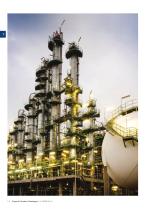

Introduction Oil & Gas - Downstream applications 1 The term downstream relates to the processing and delivery of finished carbon related product to the end-uster. This covers a whole range of applications from refining to petrol stations. There are over 700 refineries globally all competing to supply finished carbon based products to local and international markets. The products refined are varied including: – Transportation fuels - LPG, gasoline, jet fuel, diesel, gas oil and bunker fuel – Petrochemical feedstocks - LPG, naphtha and aromatics – Energy sources - LPG, kerosene, heating oil and...

Open the catalog to page 12

The refining process is in four stages, firstly distillation which separates it into 5 product sectors LPG, Naphtha, Kerosine, Gas, Oil, and Atmospheric residue, this is done using high temperature. The higher the temperature the higher the quality of the product. The second stage is the upgrading or reforming. This stage is used to change the product at a molecular level for example changing the low octane version of Naphtha to high octane which can be blended into gasoline. All the stages in the downstream operation have different requirements to ensure safety of personnel and the quality...

Open the catalog to page 13

Introduction Food & Beverage applications 1 1 Food processing - Explosion proof (Dust) | 2 Beverage manufacture - Explosion proof (Vapour) Food Industry ABB offers a range of products for the food processing market, including products for use in areas where stainless steel is preferred as well as areas classified as hazardous. ABB can offer stainless steel control stations for use on automated food processing and packaging machines as well as lighting specifically designed for use in dust filled atmospheres such as flour mills or other places where the risk of explosion is considered to be...

Open the catalog to page 14

Introduction Chemical & Pharmaceutical applications 1 3 Chemical engineering - Explosion proof | 4 Pharmaceutical production - Explosion proof Chemical & Pharmaceutical Industry The ABB range of products and solutions are ideal for use in the chemical and pharmaceutical Industry. Whether it is upstream in the primary production stage or downstream in the packing stage. Many of the processes and applications used in these areas require approvals to hazardous area standards making Kopex-Ex range of conduits & cable glands ideal. Kopex-Ex Product Catalogue | LIT-166GBR 04/15

Open the catalog to page 15All Kopex International catalogs and technical brochures

-

Distribution Communication

4 Pages

-

FOX505 Access Multiplexer

2 Pages

-

FOXMAN / FOXView

2 Pages

-

TEBIT for FOX515/512

4 Pages

-

iS3000 / SIP@Net

2 Pages

-

ABB AFS660 Switch

6 Pages

-

FOX615 Multiservice Platform

5 Pages

-

ARM600 M2M gateway

2 Pages

-

Conduit Systems & Accessories

24 Pages