Website:

Konecranes

Website:

Konecranes

Group: Konecranes

Catalog excerpts

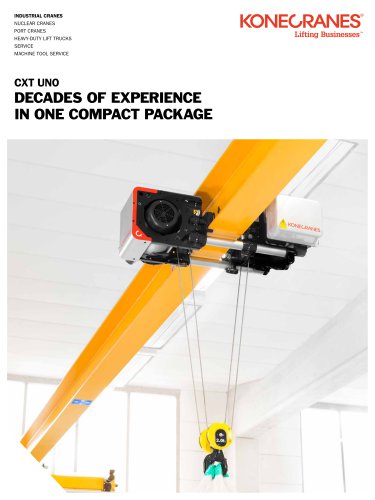

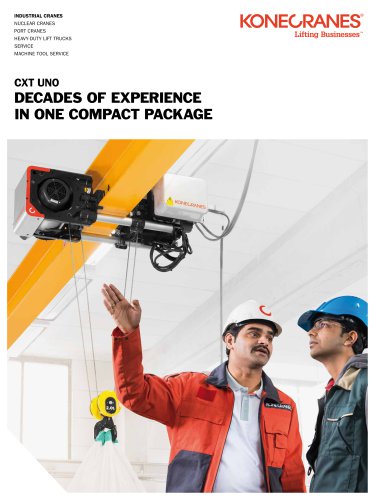

INDUSTRIAL CRANES NUCLEAR CRANES PORT CRANES HEAVY-DUTY LIFT TRUCKS SERVICE MACHINE TOOL SERVICE KONEGRANES* Lifting Businesses'"

Open the catalog to page 1

This publication is for general informational purposes only. Konecranes reserves the right at any time, without notice, to alter or discontinue the products and/or specifications referenced herein. This publication creates no warranty on the part of Konecranes, express or implied, including but not limited to any implied warranty or merchantability or fitness for a particular purpose. Konecranes standard terms and conditional apply to all orders.

Open the catalog to page 2

Redefining the standard in general lifting Preventive maintenance

Open the catalog to page 3

FREEDOM TO MOVE AND POWER TO LIFT When it comes to lifting, CXT NEO crane is a powerful machine – but also an agile one. Its ergonomic design and new MiniJoystick radio enable faster operations. Inverter hoisting provides power and accuracy with load positioning, and the TRUCONNECT®Remote Service package seals the deal. That's what we mean by redefining the standard in general lifting. OPTIMIZED MAINTENANCE ACTIVITIES based on usage data with TRUCONNECT Remote Monitoring.

Open the catalog to page 4

UP TO 12.5 TONS of lifting capacity and up to 25 tons with two similar hoists. IMPROVED SAFETY with energy chain, which protects the power and control cables from mechanical wear and reduces the risk of external damage. INCREASED ACCURACY IN LOAD CONTROL thanks to stepless hoisting speed. LONGER LIFECYCLE thanks to inverter hoisting that reduces mechanical stress on structures.

Open the catalog to page 5

Agility ENERGY CHAIN’S simplified design eliminates the need for additional parts associated with common festoon systems. SINGLE- AND DOUBLE-GIRDER CRANES WITH ENERGY CHAIN Energy chain protects the power and control cables from mechanical wear.

Open the catalog to page 7

Behind CXT NEO crane’s power is the energy-efficient inverter hoisting technology that provides accuracy with load positioning and controlled slow-speed operation. Inverter hoisting enables stepless hoisting speeds. It allows very slow speeds, which are important in moments of load lift-off and lowering. It also enables faster lifting by as much as 50%. With inverter hoisting, an empty load hook can be driven at speeds of up to 50% faster compared to a loaded hook, allowing the operator to choose the most efficient way to operate the hoist. Inverter hoisting makes soft start-ups...

Open the catalog to page 8

Power INVERTER HOISTING (ASR) technology enables faster load cycles, stepless speed control and precise load positioning. INVERTER HOISTING (ASR) TECHNOLOGY LOAD SPECTRUM & SPEEDS Speed range for inverter hoisting Occasional full load lifts Regular partial loading Medium load spectrum per FEM: Frequent handling of light loads 80% Normal speed of two-speed hoist ASR=Adaptive Speed Range Lifting Speed Inverter hoisting (ASR) motor characteristics: Fast speed for light loads Medium speed for partial loading Safety speed for heavy loads

Open the catalog to page 9

TAKING ERGONOMICS TO THE NEXT LEVEL All of the lifting power in CXT NEO crane is easy to control with the ergonomic Konecranes MiniJoystick radio. The MiniJoystick radio takes the ergonomics of controlling cranes to the next level. It is lightweight and easy to use. The joystick is for controlling the traveling movement of the crane and hoist, whereas the buttons are for lifting and lowering. The joystick allows the operator to control the load with just a single grip and enables the operator to concentrate fully on the load. MINIJOYSTICK BENEFITS • Ease of use makes operations faster •...

Open the catalog to page 10

Ergonomics MINIJOYSTICK RADIO provides freedom to move and makes speed adjustments easy. MINIJOYSTICK RADIO LIFTING AND LOWERING MOVEMENTS Push-buttons are for controlling stepless hoisting movements. EMERGENCY STOP BRIDGE AND TROLLEY MOVEMENTS The joystick is for controlling the traveling movement of the crane and hoist. MULTIFUNCTION KEY The rotatable function key makes it possible to have multiple functions for just one control element.

Open the catalog to page 11

A quality crane, properly used and well maintained, should provide years of trouble-free lifting. If you start with a great crane and then work with us to care for it professionally, predictability can improve, helping you make decisions about maintenance and productivity. SERVICE PROGRAMS THAT FIT YOUR NEEDS An active preventive maintenance program is recommended for your CXT NEO. We can create a maintenance plan based on your equipment, application and duty cycle. The CARE Preventive Maintenance Program is our most popular service offering and includes preventive maintenance inspections...

Open the catalog to page 12

Get insights into your crane usage TRUCONNECT REMOTE MONITORING uses sensors to collect data, such as running time, motor starts, work cycles and emergency stops, providing visibility to crane usage. The data is accessible on demand in the yourKONECRANES.com customer web portal where aggregated data can be viewed, analyzed and shared quickly, for a single asset or an entire fleet. TRUCONNECT REMOTE MONITORING Sensors gather usage data–running time, motor starts, work cycles and brake condition. Data is transmitted to the Konecranes Remote Data Center. Usage and maintenance data can be...

Open the catalog to page 13

CXT NEO CRANE FACTS AT A GLANCE SINGLE-GIRDER UNDER-RUNNING DOUBLE-GIRDER HEADROOM Low Normal Low Normal ASR inverter hoisting STANDARD STANDARD STANDARD STANDARD STANDARD MiniJoystick radio STANDARD STANDARD STANDARD STANDARD STANDARD Energy chain power feeding for trolley STANDARD STANDARD STANDARD STANDARD STANDARD TRUCONNECT Remote Monitoring STANDARD STANDARD STANDARD STANDARD STANDARD Extended warranty OPTIONAL OPTIONAL OPTIONAL OPTIONAL OPTIONAL RAL7035 grey color...

Open the catalog to page 14

LOAD RANGE AND DUTY CLASS Load range (tons) Duty classes ISO FEM CMAA WHEN YOU NEED MORE LIFTING CAPACITY, GET TO KNOW OUR CXT WIRE ROPE HOIST CRANES RANGE CXT cranes can be implemented with a single-girder or double-girder construction, a fixed single-girder system (monorail) or with an under-running construction. With different trolley configurations, CXT wire rope hoist cranes maximize the lifting height and easily fit into different kinds of buildings: • Low headroom trolleys up to 12.5 t • Normal headroom trolleys up to 40 t • Double-girder trolleys up to 80 t • Five frame sizes up to...

Open the catalog to page 15All Konecranes catalogs and technical brochures

-

S-SERIES

5 Pages

-

INDUSTRIAL CRANES

25 Pages

-

SMARTON® AND UNITON®

15 Pages

-

CXT UNO_2015

8 Pages

-

LIFT SMART, EVERY LIFT

8 Pages

-

Core of Liftings CONTROLS

10 Pages

-

MOTORS

5 Pages

-

Core of Liftings GEARS

6 Pages

-

REACH STACKERS WITH HEART

24 Pages

-

CXT GANTRY CRANE

3 Pages

-

A-STRAD

5 Pages

-

FLOATING CRANES

11 Pages

-

PORTAL HARBOR CRANES

11 Pages

-

Model 8 Mobile Harbor Cranes

11 Pages

-

Model 7 Mobile Harbor Cranes

11 Pages

-

MODEL 6 MOBILE HARBOR CRANES

11 Pages

-

MODEL 5 MOBILE HARBOR CRANES

11 Pages

-

MODEL 4 MOBILE HARBOR CRANES

11 Pages

-

MODEL 3 MOBILE HARBOR CRANES

11 Pages

-

MODEL 2 MOBILE HARBOR CRANES

11 Pages

-

NOT JUST A CRANE UNITON

4 Pages

-

SMARTON®

12 Pages

-

CXT® NEO CRANE

16 Pages

-

Konecranes Container LIft Trucks

24 Pages

-

Goliath Gantry Cranes

2 Pages

-

CXT Biomass Crane

12 Pages

-

Compact Conductor Systems

3 Pages

-

CLX Chain Hoist Crane

12 Pages

-

Automotive Industry

8 Pages

-

Automated RTG

12 Pages

-

ATL Vertical Lifter

3 Pages

-

ATB AirBalancer

4 Pages

-

AGD Grab Unloader

6 Pages

-

WORKSTATION LIFTING SYSTEMS

16 Pages

Archived catalogs

-

CXT UNO_2014

8 Pages