Website:

Konecranes

Website:

Konecranes

Group: Konecranes

Catalog excerpts

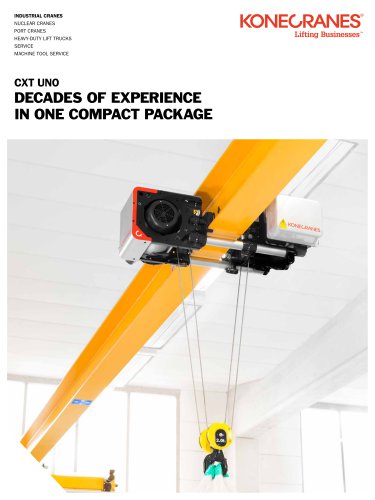

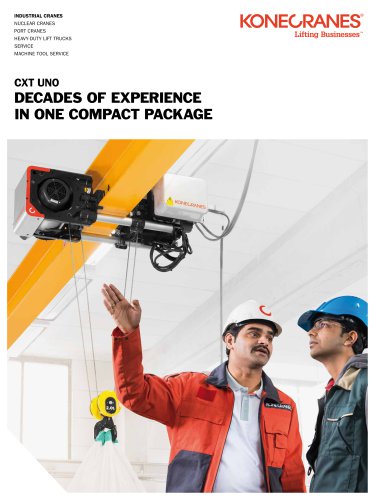

iNDUSTRiAL CRANES NUCLEAR CRANES PORT CRANES HEAVY-DUTY LIFT TRUCKS SERVICE MACHINE TOOL SERVICE KONEGRANES*Lifting Businesses" CXT® BIOMASS CRANE OPTIMAL SOLUTION FOR BIOMASS POWER PLANTS

Open the catalog to page 1

CXT®Biomass Crane WE KNOW BIOMASS Some of the most challenging locations for heavy-duty crane applications exist in the renewable energy industry. Konecranes has 50 years of experience in meeting the rigorous demands of renewable energy plants. We know your process, and we have taken its requirements into account in our crane design. Our optimized biomass software enables fully automated cranes to perform biomass handling efficiently and reliably, and by letting us take care of maintenance, you can fully concentrate on your core business. All of this is possible with our global knowledge...

Open the catalog to page 2

efficient biomass handling with fully automated crane. RELIABLE GRAB USE thanks to specially designed CXT®trolley. ACCURATE AND SAFE lifting with Smart Features.

Open the catalog to page 3

CXT®Biomass Crane SAFER, SMARTER AND AGILE Our deep knowledge of the biomass process has helped us to design a solution that is suitable for most biomass handling needs, the CXT® Biomass -a fully automated, versatile, and reliable crane with a compact and robust design. CXT®Biomass is packed with valuable features. A hoisting inverter with Extended speed Range (EsR) provides smooth and fast operation and reduced cycle times. TRuconNEct® remote Monitoring and reporting eases your maintenance stress with real usage information. smart Features such as sway control and slack rope prevention...

Open the catalog to page 4

CXT®BIOMASS CRANE is a fully automated, completely operator-free system. The crane takes care of the fuel material management all by itself. AUTOMATIC CYCLES The receiving cycle is used for moving biomass from the dumping area to the storage area. trucks usually unload during standard working time. the crane picks up biomass from the dumping area and drops it into the storage area or directly to the hopper. the crane clears the dumping area until the dumping bunker is empty. The feeding cycle is used to feed the hopper. this mission is working 7 days a week with the highest priority. the...

Open the catalog to page 5

CXT®Biomass Crane WE MAKE SURE THAT THE PROCESS CONTINUES Service, done properly, is not an expense. it is a business investment that provides a return. With almost 420,000 pieces of equipment under maintenance contracts, and more than 50 years behind us, our experience sets us apart. specialized maintenance AND modernization sERVICEs Through our global service network, we offer specialized maintenance and modernization services for all types of industrial cranes. these services range from mandatory inspections to preventive or full-service maintenance and operations partnerships. they can...

Open the catalog to page 6

truconnect®remote monitoring and reporting Crane Condition Monitoring Centralized Data Handling Safety, Productivity and Service Life Reporting & Alerts

Open the catalog to page 7

CXT®Biomass Crane SCALDIS IN BEINHEIM, FRANCE Scaldis is an experienced provider in the field of biomass handling. Scaldis’ client in Beinheim wanted to diversify its steam production that is traditionally based on gas, and it required a new biomass boiler. scaldis contacted Konecranes to design a solution for the boiler’s feeding cycle together. THE CHALLENGE The crane needed to fulfill a multitude of important requirements. It needed to have sufficient capacity to provide the boiler's consumption flow and to fit to the building within the constraints of the passage and headroom sizes. the...

Open the catalog to page 8

CXT®Biomass Crane NEW HEAT IN KAUNAS, LITHUANIA ASSURING A CONTINUOUS FLOW OF FUEL New Heat, a recognized EPC provider of boiler houses and combined heat and power (CHP) plants, constructed, for Lorizon energy, a new biomass power plant located in Kaunas, Lithuania. The plant is equipped with a 10 MW boiler house, where heat is produced. The plant is capable of using three different types of biomass - straw pellets, wood chips, and peat. THE CHALLENGE The biomass power plant is designed to be operated 24/7 by only one person. this sets high demands on the automation level, safety, and...

Open the catalog to page 10

Nuclear Cranes Port Cranes Heavy-duty Service Lift Trucks Machine Tool Service Konecranes is a world-leading group of Lifting Businesses™ offering lifting equipment and services that improve productivity in a wide variety of industries. The company is listed on NASDAQ OMX Helsinki Ltd (symbol: KCR1V). With over 12,000 employees at more than 600 locations in almost 50 countries we have the resources, technology and determination to deliver on the promise of Lifting Businesses™. © 2013 Konecranes. All rights reserved. ‘Konecranes’, ‘Lifting Businesses’ and are registered trademarks of...

Open the catalog to page 12All Konecranes catalogs and technical brochures

-

S-SERIES

5 Pages

-

INDUSTRIAL CRANES

25 Pages

-

SMARTON® AND UNITON®

15 Pages

-

CXT UNO_2015

8 Pages

-

LIFT SMART, EVERY LIFT

8 Pages

-

Core of Liftings CONTROLS

10 Pages

-

MOTORS

5 Pages

-

Core of Liftings GEARS

6 Pages

-

REACH STACKERS WITH HEART

24 Pages

-

CXT GANTRY CRANE

3 Pages

-

A-STRAD

5 Pages

-

FLOATING CRANES

11 Pages

-

PORTAL HARBOR CRANES

11 Pages

-

Model 8 Mobile Harbor Cranes

11 Pages

-

Model 7 Mobile Harbor Cranes

11 Pages

-

MODEL 6 MOBILE HARBOR CRANES

11 Pages

-

MODEL 5 MOBILE HARBOR CRANES

11 Pages

-

MODEL 4 MOBILE HARBOR CRANES

11 Pages

-

MODEL 3 MOBILE HARBOR CRANES

11 Pages

-

MODEL 2 MOBILE HARBOR CRANES

11 Pages

-

NOT JUST A CRANE UNITON

4 Pages

-

SMARTON®

12 Pages

-

CXT® NEO CRANE

16 Pages

-

Konecranes Container LIft Trucks

24 Pages

-

Goliath Gantry Cranes

2 Pages

-

CXT Biomass Crane

12 Pages

-

Compact Conductor Systems

3 Pages

-

CLX Chain Hoist Crane

12 Pages

-

Automotive Industry

8 Pages

-

Automated RTG

12 Pages

-

ATL Vertical Lifter

3 Pages

-

ATB AirBalancer

4 Pages

-

AGD Grab Unloader

6 Pages

-

WORKSTATION LIFTING SYSTEMS

16 Pages

Archived catalogs

-

CXT UNO_2014

8 Pages