Website:

Konecranes

Website:

Konecranes

Group: Konecranes

Catalog excerpts

SAFETY IN EVERY DETAIL WELL-DESIGNED CONTROLS MEAN A SAFER CRANE EXCELLENT SOFTWARE MAKES AN EXCELLENT CRANE SMART FEATURES FOR MORE FLEXIBLE LIFTING IT GETS EVEN EASIER WITH AUTOMATION MOTOR CONTROLS JUST FOR CRANES COLLECTING, READING AND UNDERSTANDING DATA

Open the catalog to page 1

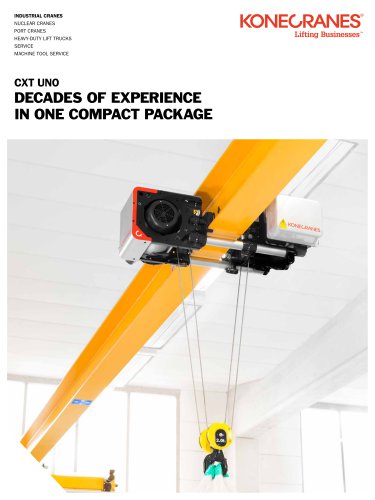

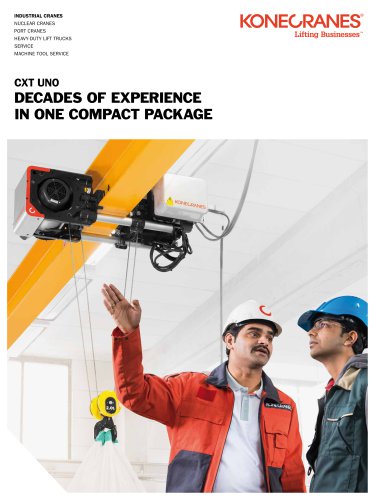

Konecranes equipment is renowned for excellent safety, reliability and ease of use. To make sure that every one of our cranes lives up to this reputation, the mechanics, software and electronics that control the crane are designed to work in unison. Advances in technology make our lifting equipment more sophisticated, but our user interfaces are clear and straightforward, helping operators drive the crane efficiently and aiding technicians in maintenance tasks.

Open the catalog to page 2

We make our physical controls with both safety and simplicity in mind. A crane that is easy to use gives the operator full control over the load at all times. With controls carefully engineered and integrated into our cranes, load handling is safer and easier. On basic model cranes, the control unit might only have buttons for stop-start motions like lifting and lowering loads. More advanced lifting equipment uses one or two joysticks, or even a detachable tablet computer to help use a wide range of Smart Features. Konecranes control units are ergonomically designed for operator comfort and...

Open the catalog to page 3

Software controls and monitors the physical movements of the crane. The first thing to consider is safety, especially creating limits that restrict what the crane can do and where it can go. Crane software must be able to deal with any errors that might occur, and usage data and diagnostics must be reliable and secure. AT KONECRANES, WE WRITE ALL OUR OWN CRANE CONTROL SOFTWARE. Our industry knowledge and programming acumen give us the ability to choose the right software according to customer need. The right software can ease the daily work of operators and maintenance personnel, and...

Open the catalog to page 4

Konecranes Smart Features represent the most advanced crane technology on the market today. You can change the speed of your movement, control the sway on your load, prevent your ropes from going slack, position your load more accurately, and even synchronize with other hoists for a dual lift. These and many other options are available with Smart Features. These features can help you achieve more efficient load handling, shorter and faster work cycles, safer lifting operations, and a longer'craneSlifetime. Smart Features can be installed on both new cranes and ongjpur existing

Open the catalog to page 5

IT GETS EVEN EASIER WITH AUTOMATION KONK With a lot of computer technology, the logical next step is automation. The more automated the crane, the easier the work of the operator. With fully automated processes, the crane can work without a human operator. From the earliest days of crane automation, we at Konecranes have been developing our own automated systems and driving the technology forward. This technology has been tested and field proven in thousands of applications with various customers.

Open the catalog to page 6

General-purpose inverters optimized for use with pumps and fans just don’t have the vigorous power and torque response needed for safe, reliable, and precise crane operations. We write our own crane application software, taking full advantage of our years of experience and knowledge of our customers and their applications, mi /mi i iif een xi lire i it i-iun Because we develop all of our key technology in-house, you can be sure of expert technical support throughout the lifetime your crane. We also have the tools for long-term software management. Crane drive systems are facing ever-growing...

Open the catalog to page 7

Konecranes DynAHoist technology includes a safety device - the Speed Supervision Unit (SSU) - that constantly monitors the load speed and motor response. The SSU is integrated into the drive hardware as an option board, but runs independent of all other functions of the drive. The power range of the DynA Vector II covers drives from 2.2 kW, up to 1MW and above. With common DC-bus and loadsharing applications, the power range of DynA Vector II covers all crane applications. Modularity is key in the DynA family Every drive, from the smallest cross-travel drive to the largest common DC-BUS...

Open the catalog to page 8

Technology has revolutionized the way we capture, share and consume information. Konecranes Remote Service brings the benefits of the Industrial Internet to material handling by connecting data, machines and people. Konecranes TRUCONNECT Remote Monitoring uses sensors to collect data, such as running time, motor starts, work cycles and emergency stops, providing visibility to crane usage. It also provides brake and inverter monitoring. Your data is available at any time on our online customer portal. TRUCONNECT Remote Support provides 24/7 access to a global network of crane experts and...

Open the catalog to page 9

READ MORE ABOUT CORE OF LIFTING FOLLOW US ill LINKEDIN # TWITTER O YOUTUBE ' CONTACT US Konecranes is a world-leading group of Lifting Businesses™ offering lifting equipment and services that improve productivity in a wide variety of industries. The company is listed on Nasdaq Helsinki Ltd (symbol: KCR1V). With approximately 12,000 employees at 600 locations in nearly 50 countries we have the resources, technology and determination to deliver on the promise of Lifting Businesses™. © 2016 Konecranes. All rights reserved. ‘Konecranes’, ‘Lifting Businesses’, C, TRUCONNECT, CXT, are either...

Open the catalog to page 10All Konecranes catalogs and technical brochures

-

S-SERIES

5 Pages

-

INDUSTRIAL CRANES

25 Pages

-

SMARTON® AND UNITON®

15 Pages

-

CXT UNO_2015

8 Pages

-

LIFT SMART, EVERY LIFT

8 Pages

-

MOTORS

5 Pages

-

Core of Liftings GEARS

6 Pages

-

REACH STACKERS WITH HEART

24 Pages

-

CXT GANTRY CRANE

3 Pages

-

A-STRAD

5 Pages

-

FLOATING CRANES

11 Pages

-

PORTAL HARBOR CRANES

11 Pages

-

Model 8 Mobile Harbor Cranes

11 Pages

-

Model 7 Mobile Harbor Cranes

11 Pages

-

MODEL 6 MOBILE HARBOR CRANES

11 Pages

-

MODEL 5 MOBILE HARBOR CRANES

11 Pages

-

MODEL 4 MOBILE HARBOR CRANES

11 Pages

-

MODEL 3 MOBILE HARBOR CRANES

11 Pages

-

MODEL 2 MOBILE HARBOR CRANES

11 Pages

-

NOT JUST A CRANE UNITON

4 Pages

-

SMARTON®

12 Pages

-

CXT® NEO CRANE

16 Pages

-

Konecranes Container LIft Trucks

24 Pages

-

Goliath Gantry Cranes

2 Pages

-

CXT Biomass Crane

12 Pages

-

Compact Conductor Systems

3 Pages

-

CLX Chain Hoist Crane

12 Pages

-

Automotive Industry

8 Pages

-

Automated RTG

12 Pages

-

ATL Vertical Lifter

3 Pages

-

ATB AirBalancer

4 Pages

-

AGD Grab Unloader

6 Pages

-

WORKSTATION LIFTING SYSTEMS

16 Pages

Archived catalogs

-

CXT UNO_2014

8 Pages