Website:

Komax AG

Website:

Komax AG

Group: Komax

Catalog excerpts

The Alpha 565 is a flexible and expandable wire processing machine with seven process of two-sided crimp and seal insertion, the HIGH FLEXIBILITY Alpha 565 also offers plenty of space for FOR YOUR FUTURE REQUIREMENTS modules. In addition to its core functions special processing, e.g. application of ferrules or MIL crimps, tinning, twisting, solidifying, ultrasonics, welding and much more. The conductor cross section range of 0.13 mm² to 6 mm² covers all common requirements. The proven Alpha 550 technology provides the perfect base for integrating customer-specific applications easily and...

Open the catalog to page 2

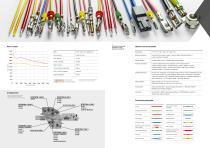

FOR UP TO SEVEN PROCESS MODULES SEAL MODULE TWISTING MODULE CRIMP MODULE FLUXING/TINNING MODULE FERRULE MODULES Q1250 SCALABLE OPTICAL CRIMP MONITORING SLEEVE MODULE

Open the catalog to page 3

X1582 twisting module Twisted strand ends are the ideal basis for carrying out tinning rapidly and with pinpoint accuracy. The X1582 twisting module twists stripped wire ends in a wide range of dimensions. The twisting process Q1250 scalable optical crimp is very precise, ensuring that no strands are damaged – even for extremely thin The Q1250 scalable quality assurance module runs an optical check on the strip quality and automatically rejects defective products. X1585 fluxing/tinning module The X1585 fluxing/tinning module for Komax fully automated machines enables Seal monitoring is also...

Open the catalog to page 4

Technical data Conductor cross section* Wire retraction speed Wire outer diameter Length range** Full strip Partial strip Crimp force* Process module side 1 / 2 Noise level < 80 dB (without crimp tool) Electrical connection Air consumption crimp / crimp crimp seal / crimp seal Weight (incl. 2 crimp modules) * Komax offers feasibility tests for advance testing. Processing of larger conductor cross sections possible on request. ** Repeat accuracy ± (0.2% + 1 mm [0.04in.]) Wire deposit basic module 2 m: 4120 mm (162.2 in.) Wire deposit basic module 4 m: 6120 mm (240.9 in.) Height with closed...

Open the catalog to page 5

Piece output A variety of processing options for a large selection of contacts. Blade holders Double-blade line for V-blades and special blades Process modules C1370/C1360/C1340 crimp module • S1441 seal module • X1582 twisting module • X1585 tinning module • Sleeve module • Double gripper module • AEH ferrule module • MIL crimp module • Welding module • Ultrasonic compaction Quality assurance Deposit gripper Komax 341 integrated crimp height measurement • Q1210 integrated pull-off force measurement • Q1250 scalable optical crimp monitoring • Automatic conductor detector ACD • Material...

Open the catalog to page 6

Komax – leading the field now and in the future As a pioneer and market leader in automated wire processing, Komax provides its customers with innovative solutions. Komax manufactures series and customer-specific machinery, catering to every degree of automation and customization. Its range of quality tools, test systems, and intelligent software and networking solutions complete the portfolio, and ensure safe, flexible, and efficient production. Komax is a globally active Swiss company with highly qualified employees and development and production facilities on several continents. It provides...

Open the catalog to page 7All Komax AG catalogs and technical brochures

-

KTL 10

8 Pages

-

KTR 1800

8 Pages

-

Q1250 scalable

5 Pages

-

M1650 Tube

3 Pages

-

F1110 Wire feeding system

3 Pages

-

X1592

3 Pages

-

F1160

3 Pages

-

Mira 440 Series

5 Pages

-

Mira 230 / Mira 230 Q

5 Pages

-

C1370/C1340 Crimping modules

4 Pages

-

Iota 330

4 Pages

-

M1630 Jet eco

5 Pages

-

Gamma 450 Crimping machine

7 Pages

-

SmartVision

3 Pages

-

Zeta 640 / Zeta 650

7 Pages

-

Zeta 630 Crimping machine

7 Pages

-

Sigma 688 ST

7 Pages

-

S1441 Seal module

3 Pages

-

QCenter

3 Pages

-

Omega 740 / 745 / 750 / 755

9 Pages

-

Mira CC/IO

3 Pages

-

Mira 32 Wire stripper

5 Pages

-

MIKO – Software & Networking

3 Pages

-

MicroPull 10

3 Pages

-

MicroLab 55

3 Pages

-

MicroLab 35

3 Pages

-

MicroLab 30

3 Pages

-

MicroLab 10

3 Pages

-

MicroForce 80

3 Pages

-

MicroForce 70

3 Pages

-

M1630 Jet

5 Pages

-

KRI 450/850

3 Pages

-

Komax HMI

5 Pages

-

Komax Cloud MES

5 Pages

-

Wire feeding systems

5 Pages

-

DLW

5 Pages

-

Delta Series

5 Pages

-

C1380 Crimping module

3 Pages

-

C1360 Crimping module

3 Pages

-

Alpha 560 Crimping machine

7 Pages

-

Alpha 550 Crimping machine

7 Pages

-

Alpha 530 Crimping machine

7 Pages

-

Zeta 620

7 Pages

-

CS370

5 Pages

-

KTR 10

5 Pages

-

KTHB Smart

1 Pages

-

KTHB Mini

1 Pages

-

KTB E19P V2

8 Pages

-

KTB 50 E Plus

8 Pages

-

KT Drainwire

2 Pages

-

Cosmic 42R

4 Pages

-

bt 752 Crimper

4 Pages

-

bt 722 Crimper

4 Pages

-

bt 712 Crimper

4 Pages

-

Deposit Systems

6 Pages

-

mci 765 C Seals module

4 Pages

Archived catalogs

-

Q1240 Strip monitoring

4 Pages