Catalog excerpts

THE ENGINE IN THE FOREST Choosing the path for engine technology development in modern forestry.

Open the catalog to page 1

DRIVING FORCES Which factors influence engine technology development? Forest machine development has seen enormous progress since forestry mechanization first began in the 1960s. And the driving forces behind this development have seen equally large changes. In the beginning, it was mostly about optimizing production. Today, the array of requirements is far more complex and includes everything from the financial means of individual forestry contractors to the well being of the global environme

Open the catalog to page 2

Legal requirements clean the air Emission legislation prescribes an impressively healthy reduction in emissions, from the initial step in 1996 (the large dark-gray rectangle) to the fourth step in 2014 (the small blue rectangle). Global environment and climate issues have been increasingly prioritized since the 1990s. Emissions of greenhouse gases, such as nitrogen oxides (NOx), have been under the microscope. For forest machine manufacturers, this is most tangible in the emission legislation of the EU and the USA; legislation that regulates a systematic increase in emission control to cut...

Open the catalog to page 3

EMISSION CONTROL Functions, advantages, and disadvantages In terms of emission control, the new emission legislation has been fulfilled primarily by two engine technologies, CEGR and SCR, and Komatsu Forest has chosen the latter. Here we take a look at how they work and how well they fulfill the needs of modern forestry. Diesel Particulate Filter Some emission reduction CEGR technology is optimized for reduc- ing nitrogen oxides (NOx) by recirculating the exhaust gases in the cylinder and combusting them again. Particulate matter (PM) is reduced afterward by using a filter (DPF). Cooled...

Open the catalog to page 4

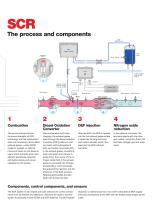

Selective Catalytic Reduction, or SCR, is a technology with which NOx is reduced afterward outside of the com- bustion process. This enables the combustion process to be optimized, reducing particulates and ensuring maxi- mum engine performance. NOx reduction takes place after combustion through the use of a urea solution (DEF, Diesel Exhaust Fluid) and a catalytic converter. The DEF is injected into the exhaust system just before the cata- lytic converter. When the mixture of exhaust gases and DEF passes through the catalytic converter, the nitrogen oxides are converted into harmless...

Open the catalog to page 5

High performance On the one hand, emission control and engine technology are separate systems. On the other hand, SCR is an emission control technology that enables the construction of highly ef- ficient engines able to deliver high performance, high torque, and lower fuel consumption. The exact same advantages that characterize Komatsu Forest's latest generation of engines. When emission control is kept outside the engine, the engine's fuel injection system and the combustion process can be finely tuned, which is the key to really high efficiency. Thanks to the latest generation of common...

Open the catalog to page 6

The process and components DEF Backflow line DEF Supply module DEF Tank Engine Temp. sensor ECU Engine coolant lines for DEF heating Actuators Engine coolant lines for cooling dosing module Dosing module Temp sensor 2 NO2 sensor 2 Diesel Oxidation Converter Nitrogen oxide reduction The environmental and performance strengths of SCR technology are that combustion does not include any recirculated exhaust gases—unlike CEGR systems. Instead, an optimal mixture of clean air and diesel is used, which provides both more efficient particulate reduction and better energy and power utilization by...

Open the catalog to page 7

The CEGR system and the DPF (Diesel Particulate Filter) What is the DPF and what does it do? The DPF is the filter required by the CEGR system to fulfill legal requirements for the reduction of particulate matter (soot). This is due to the insufficient particulate reduction in the combustion process of a CEGR system. How is the DPF prevented from being clogged by particulate matter? Soot is cleaned out through a process of active and passive regeneration. How is the DPF regenerated? Regeneration takes place in two steps. Step one is managed by the operator together with the system. The...

Open the catalog to page 9

Truck manufacturers choose SCR Cut-to-length The truck industry faces major challenges regarding energy efficiency and reduced environmental impact while confronted by increased competition from sea and rail transport. Responses to these challenges include eco-driving courses and research covering everything from convoys to alternative fuels. The transport sector also faces even tougher emission requirements than the forestry industry, which means that with today's technology a combination of CEGR and SCR must be used. Emission Technology Komatsu Forest AGCO Sisu Power John Deere John Deere...

Open the catalog to page 10

THEon the results soSTEP NEXT far and Opinions future development What experiences have been gained so far in terms of engine technology development? What are the concrete results and conclusions? And what is most important in the immediate future? Here are a few opinions from Komatsu Forest’s employees and customers. ”We’ve reduced our fuel consumption by 2-3 liters an hour.” Roland Nilsson Forest machine contractor Roland Nilsson has worked in the forest for about 40 years. He currently runs Fågelstigens Skog AB and has three employees. In June 2011, he took delivery of his new Komatsu...

Open the catalog to page 11

QUALITY ENGINES Your challenges determine our development Komatsu Forest's engine technology deve- lopment, just like all our other development work, is based on our core values, centered on the Forestry Quality concept. This means that our focus on the forest, our passion the business conditions of modern forestry determine our direction and choices. Within engine development, this means that we always strive for solutions that provide the customer with advantages in environmental impact, productivity, and operating costs. As a result, Komatsu's forest machines are among the best in the...

Open the catalog to page 12All KOMATSU Forest catalogs and technical brochures

-

901

2 Pages

-

370.2

2 Pages

-

951

8 Pages

-

370E

2 Pages

-

C144

2 Pages

-

845

2 Pages

-

835

2 Pages

-

931 Strong and smart

8 Pages

-

Grapples

2 Pages

-

ProTec Scale

2 Pages

-

XA 233-2 Introductory

2 Pages

-

XT430

8 Pages

-

XT430-3

16 Pages

-

XT430L-3

16 Pages

-

XT445

8 Pages

-

XT445L-3

16 Pages

-

XT450

8 Pages

-

XT460L-3

16 Pages

-

901 Tx

8 Pages

-

901 .4

8 Pages

-

Maxi

16 Pages

-

C93

2 Pages

-

S92

2 Pages

-

Komatsu 895

8 Pages

-

Komatsu 865

8 Pages

-

Komatsu 860.4

8 Pages

-

Komatsu 855

8 Pages

-

Komatsu 840.4

8 Pages

-

Komatsu 830.3

8 Pages

-

Komatsu 941.1

8 Pages

-

Komatsu 840TX

8 Pages

-

Komatsu 360.2

2 Pages

-

Komatsu 340

2 Pages

Archived catalogs

-

Brochure Valmet 233

2 Pages

-

Brochure Valmet 941.1

8 Pages

-

Brochure Valmet 380 & 385

2 Pages

-

Brochure Valmet 450FXL

2 Pages

-

Brochure Valmet 475FXL

4 Pages

-

Brochure Valmet 830.3

8 Pages