Catalog excerpts

TWISTER TFPL SERIES iGeneral view Oust collector Dust collector ft The 11 kW dust collector has a helghi of 140in fKThls is one example of peripheral machinery layout. •I-A safety area of 20in is required around the culling machine, A height o(24in above the lop of Iho fumo collector is required as an exhaust area. •Materials and specifications are subject to chango without notico •For a better understating of tho mechanism, iho photographs in this brochuro show the Twister without the spatter guard shield in place. Komatsu America Industries LLC Email: Salcs@Fineplasma.com TWISTER SERIES Komatsu Industries Corporation

Open the catalog to page 1

ity cutting machine" Twister" features outstanding luctivity far exceeding laser Compared to laser cutting, the Twister achieves overwhelmingly superior productivity and major cost advantages when cutting mid-thickness steel plate. cost performance Production lots and delivery times are indeterminable factors for the manufacturing sector in this age. The key words are "improved order response capability". In addition to the Twister's improved productivity, cost performance and cutting quality in the area of mid-thickness steel plate, the ease of setting up has also been improved. This...

Open the catalog to page 2

Improved productivity Exponential increase in cutting speed thanks to high power unit and high-speed twister gas (Mild Steel) Cutting speed has been increased dramatically thanks to 30kW power unit and high-speed twister gas flow. Gives about twice the cutting speed of Piercing time shortened with quick pierce Total piercing time has been shortened thanks to high speed touch sensor system and quick pierce which incorporates actions such as gas interchange in the cycle. Total piercing time per pierce Conventional type Touch sensor Quick pierce ' Comoarison with laser cutting machine 40%...

Open the catalog to page 3

Cutting quality has been improved by main gas flow control Hole Outor circumforonco Flow pattern control Holo Outer circumference match configuration The arc mode has been optimised matched to configurations by using main gas flow control. This has greatly improved cutting quality. Disparity between upper and lower hole size reduced thanks to twister gas flow control_ The twister gas flow control system ensures optimum gas flow based on configuration. This has reduced the disparity between upper and lower hole size, (us Patent No.6222154) Small — Hole size (mm) — Largo Mild Stool Twister...

Open the catalog to page 4

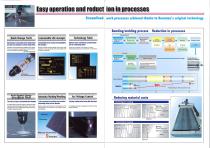

Easy operation and reduct ion in processes work processes achieved thanks to Komatsu's original technology Shortening of consumable parts replacement time due to the adoption of a quick-change torch. Unitization o( consumable parts enables off-line setup. The time required for replacement of consumable parts on site has been greatly reduced. One minute setup time Anti-Spatter Spray throughout Torch Torch oil let reduces consumable parts damage A spatter splash prevention agent is sprayed out from the Up of the torch lo the pierce point. Due to this, damage to the consumable parts during...

Open the catalog to page 5

W Komatsu nesting auto programming system [Metric Dimensions only] ramming svstem Fast - Efficient -Simple- Automatic programming system which maximizes the performance of metal working machinery Improved cost performance! Equipped with functions to ensure faster programming and lower costs Higher speed call up of require parts Actual auto nesting facilitating parts-in-parts is standard equipment Materials and specifications are subject to change without notice

Open the catalog to page 6All Komatsu Construction and Mining Equipment catalogs and technical brochures

-

GD655-7

18 Pages

-

PC45MR-5

20 Pages

-

PC35MR-5

20 Pages

-

GD655-6

16 Pages

-

BBX50

8 Pages

-

D61EXi-23 / D61PXi-23

16 Pages

-

D475A-5SD

14 Pages

-

D37EX-23

16 Pages

-

PC27MR-3

8 Pages

-

PC55MR-5

20 Pages

-

PC78US-10

20 Pages

-

D475A-5 Crawler Dozer

14 Pages

-

D375A-6

14 Pages

-

HD1500-7 Off-Highway Truck

12 Pages

-

HD785-7

14 Pages

-

HD465-7 Off-Highway Truck

12 Pages

-

HM300-5 Articulated Truck

20 Pages

-

D65WX-17

16 Pages

-

PC8000-6 Mining Shovel

8 Pages

-

PC228USLC-8 Hydraulic Excavator

20 Pages

-

PC290LC-11 Hydraulic Excavator

24 Pages

-

PC290LC-10 Super Long Front

12 Pages

-

PC88MR-10

20 Pages

-

XT445 Brochure

8 Pages

-

XT430 Brochure

8 Pages

-

IC Pneumatic: EX50 Series

12 Pages

-

IC Pneumatic: DX50 Series

8 Pages

-

IC Pneumatic: CX50 Series

12 Pages

-

IC Pneumatic: BX50 Series

4 Pages

-

IC Pneumatic: AX50 Series

4 Pages

-

IC Cushion: AX50 Series

4 Pages

-

IC Cushion: BX50 Series

6 Pages

-

E2W Catalog & Specs

8 Pages

-

Rasor Rev Brochure

2 Pages

-

H1F Catalog & Specs

8 Pages

-

OBS Catalog & Specs

8 Pages

-

Rasor 5x10 Brochure

2 Pages

-

PC1250-8

23 Pages

-

PC390LC-10

20 Pages

-

PC228USLC-8

20 Pages

-

WA430

6 Pages

-

WA470

6 Pages

-

WA320

8 Pages

-

WA200PZ-6

12 Pages

-

WA150-6

12 Pages

-

HD605-7

12 Pages

-

HD325-7

12 Pages

-

PC8000 Shovel

8 Pages

-

PC5500-6 Shovel

8 Pages

-

PC490LC-10

24 Pages

-

PC170LC-10

4 Pages

-

PC138USLC-10

24 Pages

-

D39EXi-23

16 Pages

-

D39EX-23

16 Pages

-

D37PXi-23

16 Pages

-

D37EXi-23

16 Pages

-

HD405-7

12 Pages

-

860E-1K

16 Pages

-

930E-4SE

4 Pages

-

960E-2

16 Pages

-

960E-2K

16 Pages

-

PC130-8

12 Pages

-

PC88MR-8

8 Pages

-

PC78US-8

8 Pages

-

PC55MR-3

8 Pages

-

PC45MR-3

8 Pages

-

D475A-5

14 Pages

-

D275AX-5 With Tier 3 Engine

12 Pages

-

D155AX-7

16 Pages

-

D85PX-15, D85EX-15

12 Pages

-

D65EX-17

16 Pages

-

D61EX-23, D61PX-23

16 Pages

-

D61EX-15, D61PX-15

12 Pages

-

D51EX-22

12 Pages

-

D39PX-22

12 Pages

-

D39EX-22

12 Pages

-

D39PX-23

16 Pages

-

D37PX-23

16 Pages

-

Excavators PC35MR-3

8 Pages

-

Dozers D31PX-22

12 Pages

-

Dozers D31EX-22

12 Pages

-

Waste Handling Dozers D65

18 Pages

-

Waste Handling Loaders WA250

8 Pages

-

Wheel Loaders WA80-6

2 Pages

-

Wheel Loaders WA50-6

8 Pages

-

Trucks HM400-3

16 Pages

-

Trucks HM300-3

16 Pages

-

Shovels PC3000-6 Shovel

8 Pages

-

Shovels PC2000-8 Shovel

20 Pages

-

Graders GD655-5

12 Pages

-

Excavators PC18MR-3

8 Pages

-

Excavators PC09-1

8 Pages

-

Dozers D21P-8

6 Pages

-

Dozers D21A-8

6 Pages

-

Crushers BR580JG-1

8 Pages

-

Crushers BR380JG-1

8 Pages

Archived catalogs

-

KOMATSU Product Guide

56 Pages

-

PC350HD-8 MH

10 Pages

-

HB215LC-1

16 Pages

-

GD655-3

12 Pages

-

BR550JG-1

8 Pages

-

830E

4 Pages

-

PC3000 Super Shovel

8 Pages

-

PC300LC-8

20 Pages

-

WA450-6

12 Pages

-

SK1026-5

8 Pages

-

C60R-1A

4 Pages

-

WB146-5, WB146PS-5

10 Pages