Catalog excerpts

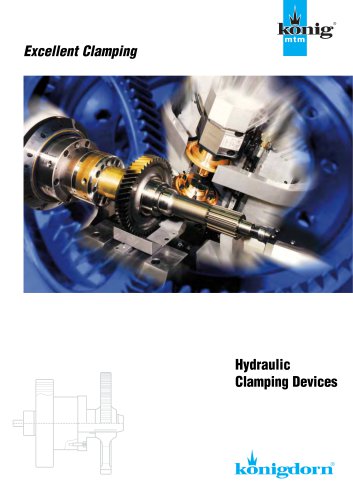

Excellent Clamping Hydraulic Clamping Devices

Open the catalog to page 1

Hydraulic Clamping Devices for High Precision and High Productivity Experience in clamping technology König-mtm's hydraulic clamping devices Product features For decades, König-mtm has been one of the leading manufacturers of state-of-the art highprecision clamping devices. The extensive production program covers clamping tools such as mandrels and chucks in hydraulic, mechanical or hydro-mechanical versions. Machining tolerances that were inconceivable years ago have become reality today. Modern CNC-contolled machine tools as well as highprecision bearings and guide ways have offered...

Open the catalog to page 2

The König quality strategy While our highly motivated and qualified staff are a substantial base of our quality strategy, our quality management system is in accordance to ISO 9001:2000 standards. In addition, Koenig-mtm maintains ISO14001:2004 certification, pertaining to environmental and industrial saftey, thus re-enforcing our desire and need to operate in an environmentally sustainable manner. The Königdorn® devices are produced on efficient state-of-the-art CNC-controlled machinery with high-quality materials. To meet the precision requirements, the functions of every Königdorn®...

Open the catalog to page 3

Customized Clamping Devices for all Requirements Clamping sleeve with a solid clamping surface Predestinated for almost all machining tasks Long life time, high productivity and high efficiency A Königdorn® clamping device, like a mandrel or chuck operates hydraulically without any mechanical wear. Its main characteristic is the elastic clamping sleeve with a solid clamping surface. The clamping sleeve, hydraulically actuated, works on the entire clamping surface. Therefore, high load torque settings can be transfered, making Königdorn® devices suitable for almost all machining tasks. Made...

Open the catalog to page 4

Königdorn® clamping technology Power clamping Königdorn® clamping devices are available with several different actuating methods depending on customer's machining tasks or machine layouts. The four most common options are illustrated in the graphics below. Manually clamping, without a wrench The clamping pressure can be generated mechanically, pneumatically, hydraulically or electromagnetically by pulling or pushing the clamping piston. Therefore this process is suitable for semi or fully-automatic machine tools. Clamping by external pressure generation Approved method at measuring and...

Open the catalog to page 5

Königdorn® Design Principles Depending on machining tasks and operating conditions Königdorn® tools can be designed in different principles. On one side they can be designed as a closed system where clamping sleeve and base are connected in a fixed manner on the other side there are open systems available where the clamping sleeve can be replaced when worn or damaged. Central clamping force initiation This brochure introduces various applications of Königdorn® clamping devices. We show no measurements and technical details as the drawings are meant to stimulate the creativity of the...

Open the catalog to page 6

Hydraulic Clamping Tools Hobbing Workpiece clamping during hobbing Based on its high precision and extremely small grinding stock allowance the Königdorn® tooling as clamping mandrel or chuck is an ideal tool for hobbing. The left drawing illustrates a clamping mandrel where the entire torque is created via radial expansion. Clamping is initiated via the clamping cylinder of the machine spindle. The tailstock, which is also clamped via the clamping mandrel, only serves the purpose of stabilizing and centering the Königdorn® device. Axial clamping is not necessary in this case. With the help...

Open the catalog to page 7

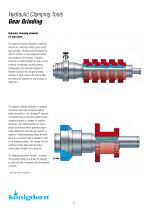

Hydraulic Clamping Tools Gear Grinding Hydraulic clamping mandrels for bore parts The opposite drawing illustrates a clamping mandrel for clamping multiple gears during gear grinding. The gears are first aligned outside the machine in a pre-alignment station and clamped on the mandrel. Clamping pressure is initiated radially by hand or via an electrical or pneumatic screwing device. Subsequently, the prepared Königdorn® mandrel is placed into the gear grinding machine. A taper mount in the tool spindle will ensure the required run-out accuracy of 0.003 mm. The opposite drawing illustrates a...

Open the catalog to page 8

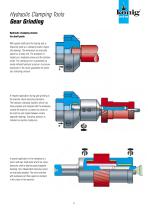

Hydraulic Clamping Tools Gear Grinding Hydraulic clamping chucks for shaft parts With geared shaft parts the bearing seat is frequently used as a clamping location (opposite drawing). The workpieces are manually placed on a study rest. The workpiece is loaded via a headstock sleeve and the tailstock center. The clamping force is generated via axially initiated hydraulic pressure. A pressure transducer in the chuck guarantees the necessary clamping pressure. A frequent application during gear grinding is the mandrel-chuck clamping alternative. The hydraulic clamping mandrel, which has been...

Open the catalog to page 9

Hydraulic Clamping Tools Gear Grinding Hydraulic clamping mandrels for workpieces with geared and smooth bore Königdorn® mandrel with two clamping locations and externally geared clamping bushing for the mounting of workpieces to be ground as a helical gear (opposite drawing). Through both clamping locations optimal centering is achieved on the entire workpiece length. Mounting between center and collet chuck, initiation of clamping force is radial by hand. Run-out accuracy: 0.005 mm. Hydraulic clamping mandrel, mounted on a quick change chuck with integrated pressure transducer (opposite...

Open the catalog to page 10

Hydraulic Clamping Tools Gear Grinding Workpiece and diamond dressing wheel clamping on one Königdorn® Workpiece and diamond dressing wheel clamping on one Königdorn® device. With this combination Königdorn® mandrel and chuck, a hollow shank shaft and the diamond dressing wheel are simultaneously clamped. If desired, the mandrel can be braced via a tailstock center. A special mounting taper makes a run-out of 0.003 mm possible. Hydraulic Königdorn® device for mounting workpiece, workpiece stop, and diamond dressing wheel. Dressing wheel and workpiece stop are clamped manually. Workpiece...

Open the catalog to page 11All König mtm GmbH catalogs and technical brochures

-

Quick-change_chucks

4 Pages

-

Nullpunkt-Spannsystem

2 Pages

-

mechanical_clamping_tools

12 Pages