Website:

König Maschinen GmbH

Website:

König Maschinen GmbH

Catalog excerpts

REX PROGRAM AUTOMATIC DOUGH DIVIDING AND ROUNDING MACHINES

Open the catalog to page 1

LET‘S MAKE SUCCESS OUR COMMON CAUSE! THE REX FAMILY OFFERS SOMETHING FOR EVERYBODY It was in 1969, when Neil Armstrong walked on the moon, referring to this achievement as a “giant leap for mankind”. In the same year, another great launch took place, namely the introduction of the Rex prototype, which was to revolutionise the baking Industrie. The first Rex made work considerably easier for bakers without requiring them to alter their traditional processes, craftsmanship and product quality. The launch of this unit marks the beginning of the success story of Koenig. Thanks to consistent and...

Open the catalog to page 2

GENTLE DOUGH HANDLING AND PRECISION WEIGHING DIVIDING AND ROUNDING WITH THE REX PRINCIPLE There is hardly anything more challenging than striking a balanced compromise between diverging interests. The task of dividing and rounding is just such a challenge. On the one hand, the dough should be processed with great care. On the other hand, the weight requirements must be met throughout the production process. The technological leadership of Koenig is not least due to the company‘s capacity to provide satisfactory solutions for problems that its customer encounter. Thanks to extensive research...

Open the catalog to page 3

MINI REX MULTI AND MINI REX FUTURA TWINS THAT ARE NOT QUITE IDENTICAL It is thanks to continued product development and improvement that Koenig became the market leader for bakery equipment. One of the keys to its success was the launch of the compact Mini Rex system. This head machine range caters for automated dividing and rounding of wheat and mixed doughs with a rye content of maximum 40%. Throughput rates of 1,200 to 4,800 units per hour and the attractive price have made the Mini Rex the preferred solution for both in-store bakeries and industrial producers. The Mini Rex can be...

Open the catalog to page 4

BASIC REX THE REX IN DIFFERENT VARIETIES Based on the gentle dough processing "Rex"principle, the Basic Rex divides and rounds dough in 6-, 5- and 4-row operation. The proved head machine offers an hourly output rate of up to 9,000 pieces. ■ ■ ■ ■ ■ ■ shaft hopper with safety cage ■ spread belt or conveyor ■ numerous accessories ■ weight approx.: 800kg (net) ■ rated power supply: 1.5kW ■ stainless steel design fully automated dividing and rounding gentle dough processing according to the Rex-principle 6-, 5- and 4-row operation easy change of the row numbers capacity stagelessly adjustable...

Open the catalog to page 5

■ weight approx.: 950kg ■ rated power supply: 2kW ■ PLC control ■ extendable weight ranges ■ max. 25 strokes/min GRANDE REX AND GRANDE REX FUTURA THE REX FOR HIGH WEIGHT RANGES The Grande Rex was developed specifically to cater for extremely large weight ranges. With this new unit, you can now process dough pieces of up to 320g in accordance with the Rex principle. This model opens up new possibilities for the production of pizza, baguettes, braided bread, Strudel strands and many more bread products on multiple rows. ■ weight approx.: 950kg ■ rated power supply: 2kW ■ relay control ■...

Open the catalog to page 6

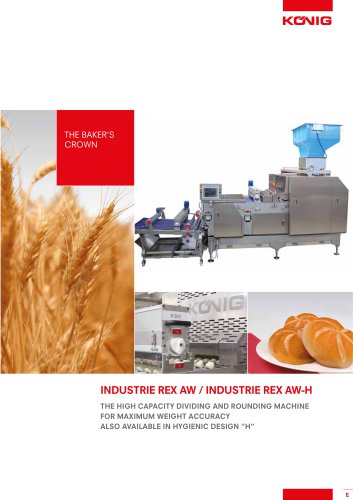

■ INDUSTRIE REX THE REX FOR HIGH OUTPUT RATES By combining harmonised design, gentle dough handling and accurate weighing, Koenig has again managed to find the optimum balance between the contradicting requirements of high product quality and fast production. In the case of the Industrie Rex, this means gentle dough handling at an hourly output rate of 42,000 pieces and more. For high weight ranges - Industrie Rex Plus. ■ weight approx.: 1,500kg ■ rated power supply: 6kW ■ PLC control ■ changeable drum ledges ■ max. 50 Strokes/min The Industrie Rex ist also available as version HD (hard...

Open the catalog to page 7

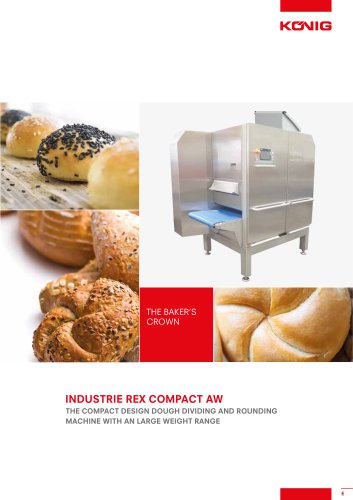

THE BENCHMARK FOR WEIGHT ACCURACY There is hardly anything more challenging than striking a balanced compromise between diverging interests. On the one hand, the dough should be processed with great care. On the other hand, highest weight accuracy demands must be met throughout the entire production process. The description AW (accurate weight) stands for these two requirements. the automatic dough dividing and rounding machine can operate in up to 12 rows and has a weight range of 22-150g hourly capacity of 43,200 pieces (60 strokes/min) the continuously adjustable, absolutely even pusher...

Open the catalog to page 8

FOR ENLARGED PRODUCT VARIETYREX WITH FORMING STATION OR COMPACT LINE MINI REX MULTI | FUTURA WITH FORMING STATION DR-RR 400 THE STAR IN EVERY IN-STORE BAKERY ■ can be combined with Mini Rex Multi as well as Mini Rex Futura ■ product varieties see last page ■ 2-row operation ■ weight range according head machine ■ hourly capacity adjustable up to 4,000 pieces ■ top belt with two speeds for transfer, long rolling and flattening ■ adjustable calibrating roller folding net belts ■ teflon-coated collecting tray for manual product removal ■ top- and bottom belt can be swivelled out ■ excellent...

Open the catalog to page 9

♦ at 3 row operation minumum dough yield of 156 required 11

Open the catalog to page 11

G 2000: rounded, folded and long rolled (German „Schrippe"), rounded and stamped long rolled and sliced (Option) Oo GS 2000 - K: rounded, long rolled, convoluted and long rolled, round and flattened, rounded and stamped long rolled and sliced (Option) GS 2000 - SL: rounded, long rolled, convoluted and long rolled, round and flattened, oval and stamped long rolled and sliced (°ption) * with optional cutting unit Each machine and unit undergoes a number of test runs with and without dough. Most of our technicians are actually trained bakers. They assemble the machine at our premises and...

Open the catalog to page 12All König Maschinen GmbH catalogs and technical brochures

-

MIXERS & BOWL HOIST

6 Pages

-

BAKERY MACHINERY AND LINES

40 Pages

-

Stressfree Program

8 Pages

-

Industrie Rex Compact AW

4 Pages

-

Industrie Rex AW / AW-H

4 Pages

-

Rex Futura Multi

4 Pages

-

Mini Rex Multi

4 Pages

-

Mixing machines / Bowl Hoist

4 Pages

-

ROLL LINES

12 Pages