Catalog excerpts

We live „Made in Germany“ For over 45 years we have been developing and manufacturing high quality coding technology products at our site in Veitshöchheim, Germany. Our focus is on first-class quality, outstanding performance and all this in combination with unbeatable reliability. We're on i

Open the catalog to page 2

Koenig & Bauer Coding Rubrik Uncompromisingly reliable. Coding efficient, independent and individual. Offline coding with our own stack-to-stack processing is ideal for applying variable data flexibly and precisely in small and medium batch sizes outside the production line. The udaFORMAXX can be fitted with a variety of coding systems for printing on flat folding cartons, sleeves, cardboard blanks and labels. The Koenig & Bauer Coding portfolio offers you suitable models for all applications, meeting your individual coding

Open the catalog to page 3

Versatile, irrespective of industry Pharmaceuticals Serialise folding cartons and blister packs with track and trace functionality incl. camera connection. Benefit from tamper-proof coding for complete traceability throughout the production chain. Packaging Process a wide range of formats such as folding cartons, sleeves, crash lock cartons, paper blanks, block bottom bags, metal lids and much more. Print dates, batch numbers and other unique codes on packaging, with easy changeover and reproducible settings. Design your product coding more individually and easily than ever before. Print...

Open the catalog to page 4

Solutions for materials and formats udaFORMAXX offline coding systems perfectly individualise flat folding cartons, blanks and blister packaging with simple, quickly reproducible format changeover. Cosmetics and drugstore products Create the packaging design for the POS exactly as you want, even in smaller batch sizes. Product information and codes are printed precisely and reproducibly on folding cartons and other flat materials. Food Code a wide range of retail packaging just-intime for your different product ranges. Print small and medium batches with variable data such as best before...

Open the catalog to page 5

udaFORMAXX Continuous ink jet Tintenstrahldrucker Fast format setting with reproducibility for your orders enables uptime > 99 % Compatible with a wide range of different coding and scanner systems to give you Thanks to reliable, uninterrupted operation, the attractive price-performance ratio offers In comparison to average market levels.

Open the catalog to page 6

Do you want to produce more campaign, seasonal and special products? The semi-automatic offline coding system is lower-cost, safer and much faster than manual solutions. Individual information or dedications can be set up in seconds, even for small batch sizes. Do you want more flexibility for fast product changeover? The ingenious concept with adjustable settings enables you to set the magazine for feeding the printing material simply and reproducibly, to process very small to largescale products. In a nutshell. Do you value reliable production? The udaFORMAXX has multiple connections as...

Open the catalog to page 7

Technical specifications udaFORMAXX models Model versions Transport speed Controller with graphic display Parametrisation using hand scanner Integration area for coding/inspection devices Sound level Operating mode Printing mate

Open the catalog to page 8

The udaFORMAXX is an economical offline coding solution for small and medium batches that can be adapted to any task quickly and flexibly. Accessories for process optimisation Outfeed tray Shingling conveyor

Open the catalog to page 9

The perfect complement to automated production 10 Unique details and functional accessories for small and medium batch size

Open the catalog to page 10

Outfeed tray Stacking the coded folding boxes or blanks neatly at the end of offline coding makes it easier for the machine operator to remove them. Shingling conveyor As an alternative to the stacker, the shuffle board offers larger reception capacity in continuous operation and makes product removal easier. Operation Control the udaFORMAXX including the printing and coding systems via an external PC system or parameterise the entire system directly via the internal operating display. Using a hand scanner makes setting up individual jobs directly in the production environment simple and...

Open the catalog to page 11

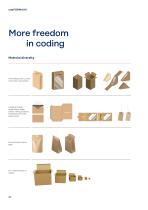

More freedom in coding Material diversity Flat folding cartons, crash lock cartons and skillets Cardboard blanks, single sheets, paper blanks, mailing products, envelopes, ISO cards, blister cards Flat and block bottom bags For a wide diversity of shapes

Open the catalog to page 12

Print samples • For variable data (e.g. best before date, batch number), 1D and 2D codes, logos With alphaJET continuous • On all substrates inkjet • Font height 0.8 - 15 mm / max. 8 lines per print head With laserSYSTEM laser coding • For permanent, tamper-proof labelling • For flexible data and codes • Economical, no consumables needed With hpdSYSTEM hot stamp • Simple, low-cost combination • For best before dates, batch numbers, prices • max. print area 50 x 80 mm With ttPRINT thermal transfer • For high-contrast print quality • Graphics and variable data e.g. content, size and...

Open the catalog to page 13

udaFORMAXX Continuous ink jet Tintenstrahldrucker 5 good reasons to choose udaFORMAXX Minimal service requirements optimise costs. Excellent availability of over 99 % provides true production reliability. Diversity of materials and shapes for maximum flexibility. Numerous equipment options make the system easy to adapt to future changes. A competent global sales and service team supports you at any time.

Open the catalog to page 14

Rubrik Daten udaFORMAXX at a glance General technical data Operation: • 4.3” graphic display with film keyboard • User-friendly user interface • Adjustable user rights • PC • Handheld scanner Accessories: • Reject station • Outfeed tray • Shingling conveyor • Individual parts for special formats • Standardised mounting brackets Power requirements: • Mains voltage (AC) 115 / 230 V • max. power input 720 VA • Ambient temperature: 15 - 30 °C • max. hum

Open the catalog to page 15All Koenig & Bauer Coding GmbH catalogs and technical brochures

-

ttPRINT

16 Pages

-

Tire & Rubber

16 Pages

-

Services

12 Pages

-

Print & Apply

16 Pages

-

Laser

16 Pages

-

Koenig-Bauer Coding

12 Pages

-

hpdSYSTEM

16 Pages

-

betaJET

16 Pages

-

alphaJET EN

16 Pages

-

alphaJET5 EN

16 Pages