Website:

KoCoS Messtechnik AG

Website:

KoCoS Messtechnik AG

Catalog excerpts

Closure diameter Working distance Operating voltage Rotary encoder input 10…30 V DC Outputs Semi-conductor output channel 24 VDC, 0.5 A Ethernet / USB Colour graphics display / keys Recipe memory Housing material Ambient temperature Light barrier Sensor holding bracket Ejector unit Ejector monitoring Collection tray System synchronisation Data transfer/ remote maintenance Vacuum sensor Unlike other measuring methods, the optical INDEC system is unaffected by the presence of single water droplets. Connection unit No problems with moisture Central unit The large measuring distance of over 100 mm rules out collisions between the sensor head and containers. Variations in the dimensions of the containers, misalignment of containers and vibrations of the conveyor are fully tolerated. Large working distance for reliable operation Semi-conductor input Optical vacuum sensor The powerful optical sensor is suitable for all common closures. A minimum distance between the containers is not required. Because of the large measuring distance, it is not necessary to adjust the sensor head manually in many cases for format changeovers involving containers of varying heights. * Necessary mounting parts/trigger sensor are provided by the customer according to KoCoS specifications Legend: included optional not available KoCoS Optical Measurement GmbH Döbereinerstr. 22 99427 Weimar, Germany Tel +49 3643 906 38-0 info@optics.kocos.com www.kocos.com INDEC VACUUM INSPECTION All housings are made of stainless steel and comply with IP69K in accordance with the principles of hygienic design. This ensures that there can be no ingress of moisture even when pressure washers are used. Technical specifications subject to change without prior notice | 202304 | © KoCoS Optical Measurement GmbH Hygienic design and protection class IP69K VACUUM INSPECTION Dud Dector INDEC monitors containers, such as bottles, jars and cans, testing them for leak tightness fully automatically within the production process by means of a non-contact inspection. Containers which show insufficient vacuum, cocked/tilted caps or missing caps are reliably identified. Whether a complete system is needed or a test device which can be equipped as required to supplement existing components: INDEC p

Open the catalog to page 1

F U L LY A U T O M A T I C Edit recipe Pass level ce Sensor distan Vertical Edit pusher Clock source Pulse length Encoder pulses Recipe Name Pulse Counter Rotary encode A new operating concept and extra powerful hardware make for easy operation and optimum display of all information. The clear, restructured user interface guides the user quickly and intuitively to complete the task in hand. The individual screens are self-explanatory and uncluttered. Touch screen with graphical user interface for Parameterization with teach-in function intuitive operation Well structured menus for fast,...

Open the catalog to page 2All KoCoS Messtechnik AG catalogs and technical brochures

-

OMCAT Series

12 Pages

-

3D inspection system

16 Pages

-

LOTOS LT

2 Pages

-

LOTOS

16 Pages

-

OMCAT

12 Pages

-

ACTAS L Series

2 Pages

-

PROMET L100s

2 Pages

-

PROMET L10

2 Pages

-

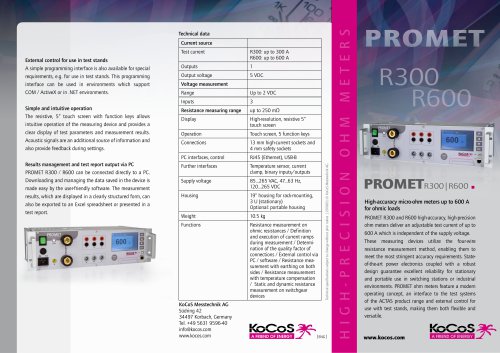

PROMET R300

2 Pages

-

PROMET SE

2 Pages

-

ACTAS BTT 2.0

2 Pages

-

EPOS MC4

2 Pages

-

EPOS CV SERIES

2 Pages

-

EPOS 360

2 Pages

-

Circuit Breaker Testing

10 Pages

-

SHERLOG CRX 2032

2 Pages

-

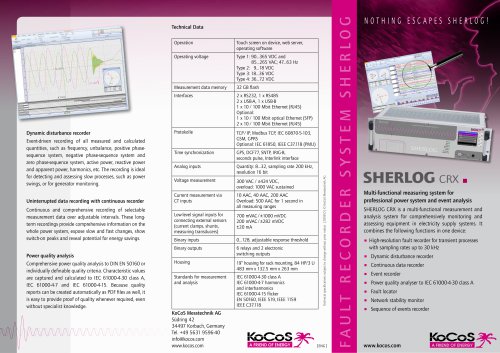

SHERLOG CRX

2 Pages

-

EPPE RX

2 Pages

-

EPPE CX

2 Pages

-

EPPE PX

2 Pages

-

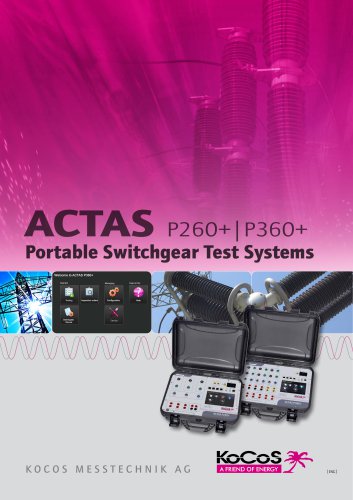

ACTAS P360+

2 Pages

-

ACTAS P260+

2 Pages

-

ARTES 600

2 Pages

-

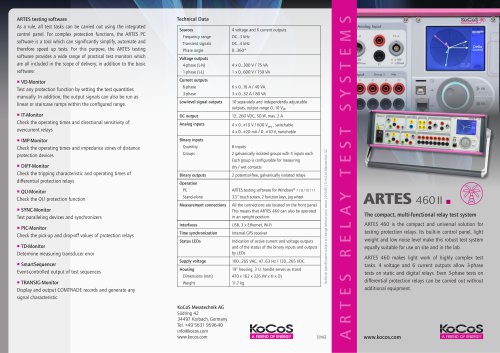

ARTES 460 II

2 Pages

-

ARTES RC3

2 Pages

-

Circuit Breaker Testing

2 Pages

-

Fault Recorder Systems

14 Pages

-

Wafer Topography Measurement

16 Pages