Catalog excerpts

Valve Trays

Open the catalog to page 1

FLEXITRAY™ Valve Trays Proven performance in all liquid-vapor contacting applications. FLEXITRAY™ valve trays combine high capacity and excellent efficiency with a wide operating range. Using proprietary design techniques and the wide range of valve types available for FLEXITRAY valve trays, design engineers at Koch-Glitsch have the knowledge and experience to assist you in optimizing performance for your application. With Koch-Glitsch technical expertise in design, manufacturing, and installation, a well-designed FLEXITRAY valve tray generally provides the most economically attractive...

Open the catalog to page 2

Valve Types Koch-Glitsch has the valve type for your application/service. Koch-Glitsch has developed a variety of valve styles to enhance the vapor-liquid contacting that takes place on a tray deck. A - Full-size, one-piece valve This is the standard, round, full-size, one-piece valve that has been used successfully in columns around the world for over 50 years. It is provided in several leg lengths to accommodate various tray deck thicknesses. It is normally dimpled to help prevent sticking to the deck, but can be flush seated if needed. The orifice can be made to prevent the valve from...

Open the catalog to page 3

T0 - Full-size, one-piece valve Characteristics This variation of the Type T valve uses an extruded orifice. The dry tray pressure drop is thus lowered, providing an overall lower pressure drop. This comes at a cost of higher weepage and reduced turndown. All the benefits of Type A valves More weepage resistance – even wider operating range Increased fouling resistance – fewer costly shutdowns Rugged construction – resistant to corrosion and erosion Contoured hole in deck for lowest possible pressure drop Equivalent Designations BALLAST™ tray: A-5 PROVALVE™ fixed valve The patented...

Open the catalog to page 4

MINIVALVE™ decks The MINIVALVE™ family of smaller-size valves provides reduced entrainment and better efficiency than conventional valve and sieve trays. The improvement in capacity can exceed 13% in spray regime services with low-to-moderate weir loadings. MINIVALVE™ valves exhibit a more uniform froth action on the tray deck compared to full-size valves. They are offered in both fixed (VG-0) and moveable (MV-1) styles. MINIVALVE valves are directional with the rear leg being a little wider than the downstream front leg. This gives a slight pushing action to the liquid as vapor passes...

Open the catalog to page 5

VG-10 - Full-size fixed valve This is a full-size fixed valve that is anything but conventional. The net rise typically ranges from 0.236 in [6 mm] to 0.551 in [14 mm], varying in 0.039 in [1 mm] increments. Other lifts may be available in some cases. This valve is also directional with the rear leg being visibly wider than the downstream front leg. As with any fixed valve, it can never stick to the deck nor can it spin. The large net rises available plus the directional liquid flow make this an outstanding anti-fouling valve. It is widely used on anti-fouling SUPERFLUX trays. Using a large...

Open the catalog to page 6

High Performance Trays from Koch-Glitsch For decades, Koch-Glitsch has been the driving force in tray design improvements. Koch-Glitsch’s design and manufacture of distillation trays have evolved from bubble cap to sieve to valve trays and now to specialty, high-capacity trays. The patented technologies used in SUPERFRAC™ and ULTRA-FRAC™ trays are the result of over twenty years of comprehensive tray development work. For new columns, Koch-Glitsch high-capacity trays can be employed to reduce diameters, heights, or both. For existing columns, they can replace existing trays to increase...

Open the catalog to page 7

Construction Details Metal Trays are available in any formable, weldable sheet metal material. The most common materials for trays are: For the trays in this brochure, Koch-Glitsch supplies all removable parts. Carbon steel Stainless steel, ferritic, austenitic, duplex, martensitic Nickel alloys Copper alloys Titanium, zirconium Trays are not normally stress relieved or annealed and typically do not conform to pressure vessel standards. Trays fabricated from sheet metal materials are typically supplied in “as-sheared” condition. The trays do not include vessel attachments for connection or...

Open the catalog to page 8

Feed Devices Obtaining desired tower performance requires the proper handling of liquid and vapor entering the column. The types of feeds or inlets into a column can generally be classified into three major categories: Mixed liquid and vapor, flashing or suppressed flash Two factors must be considered when choosing the proper device for a vapor-only feed. Good vapor distribution is essential to achieve superior separation efficiency. Poor vapor distribution is often a major source of problems. Liquid only (contains less than 1% of vapor by volume) Vapor-Only Feeds Liquid-Only Feeds Among...

Open the catalog to page 9

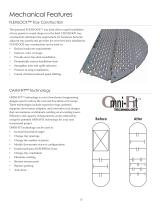

Mechanical Features FLEXILOCK™ Tray Construction The patented FLEXILOCK™ tray joint allows rapid installation of tray panels in vessel shops or in the field. FLEXILOCK tray construction eliminates the requirement for hardware between adjacent tray panels and provides for error-free deck installation. FLEXILOCK tray construction can be used to: Reduce hardware requirements Improve valve coverage Provide error-free deck installation Dramatically reduce installation time Strengthen joint and uplift tolerance Promote in-shop installations Cancel vibration-induced panel shifting OMNI-FIT™...

Open the catalog to page 10

HORIZON™ Technology HORIZON™ technology is a set of mechanical construction techniques developed specifically for in-shop installation of trays with the vessel in the horizontal position. The patented FLEXILOCK tray construction from Koch-Glitsch is the primary building block of the HORIZON technology. If you plan to shop-install trays, then you need the capabilities provided by HORIZON technology. Special mechanical design helps prevent inefficient installation sequencing, part deforming/breaking, panel shifting, joint dislodging, extra field inspecting, and field readjusting of tray...

Open the catalog to page 11All Koch-Glitsch catalogs and technical brochures

-

Metal random packing

12 Pages

-

INTALOX- ULTRA packing

8 Pages

-

Mist Elimination product catalog

20 Pages

Archived catalogs

-

Plastic Random Packing

16 Pages

-

IMTP® High Performance Packing

12 Pages

-

INTALOX® ULTRA

4 Pages

-

Structured Packing

8 Pages

-

SATURN® Technology

2 Pages

-

SPEED-WAY® Manways

2 Pages

-

FLEXILOCK® Tray Construction

2 Pages

-

OMNI-FIT® Technology

2 Pages

-

FLEXITRAY® Valve Trays

12 Pages

-

PROVALVE® Valve Trays

2 Pages