Catalog excerpts

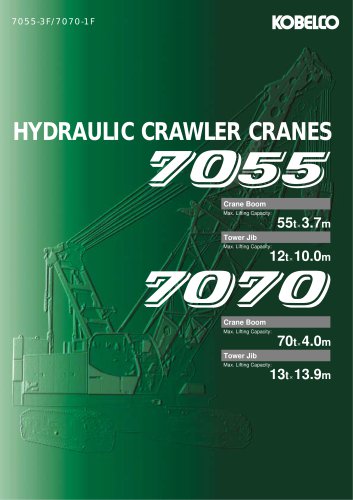

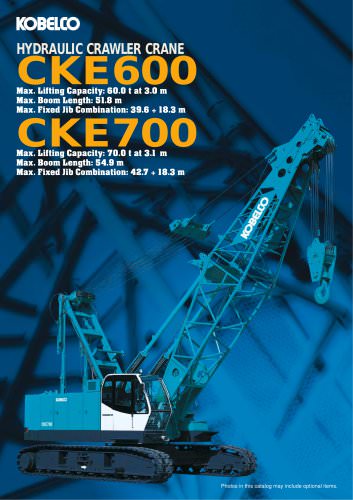

HYDRAULIC CRAWLER CRANES Crane Boom Max. Lifting Capacity: Tower Jib Max. Lifting Capacity: Crane Boom Max. Lifting Capacity: Tower Jib Max. Lifting Capacity:

Open the catalog to page 1

Technology and Power The Pride of KOBELCO 7055/7070 Hydraulic Crawler Crane The Difference Is in Its Basic Performance KOBELCO’s 7055/7070 hydraulic crawler crane features new technologies that raise performance to a new height. Precise, high-elevation crane jobs depend on accuracy and speed, while lifting for general construction jobs demands reliable safety and a sufficient working area. The versatile 7055/7070 fully meets all of these requirements in one, tough unit. Its powerful hoist winches can easily handle precise, continuous jobs, while the new hydraulic system, working in...

Open the catalog to page 2

Hydraulic Crawler Crane 7055/7070 5 Major Features 1 Global Design laSuper-Structure High-Performance Winch 2. Accommodates a Wide Range of Jobs 3Smooth Operation and 3Control 4. Reliable Safety Features 5. Multi-Function LMI Display

Open the catalog to page 3

Global Design Super-Structure Complies with Worldwide Exhaust Gas Regulations With its low pollution engine, the 7055/7070 meets NRMM (Europe) Stage IIIA and US EPA Tier III exhaust emissions regulations. Versatile Operation The 7055/7070 has the power, structural strength, safety specs, and nimble operability needed to accommodate all kinds of jobs, from standard crane work to high-rise lifting and material handling work. Complies with Japanese Noise Regulations The 7055/7070 is designed with advanced KOBELCO low-noise construction technologies, as specified by the Japanese Ministry of...

Open the catalog to page 4

Durable operation for the toughest jobs High-Performance Winch Accommodates a Wide Range of Jobs Winches with Built-In Wet-Type Disc Brakes Maintenance-Free Winch KOBELCO's proprietary winch mechanism features a built-in wet-type multi disc brake and reduction unit. This innovative design delivers greater braking power, more drum capacity and easier maintenance than ever before. Winches are maintenance-free. The built-in wet-type disc brake has a forced-oil cooling system to prevent overheating, and requires no band adjustment or lining replacement. Wet-Type Multi Disc Brake system...

Open the catalog to page 5

For greater work efficiency Visual comparison of new and conventional cabins The 7055/7070 has a new cabin design with sash-less front and top glass that provides a panoramic frontward and skylight view. The glass also has less curvature to minimize distortion. The front upper window has been broadened on both sides for a view that is 31% wider than a conventional cab, while the top-window view is widened toward the rear. Comfortable 940mm-Wide Cab ■Air conditioner ■ Fully adjustable, high backed seat with a headrest and armrests ■ Intermittent wipers and window washers ■ Sun visor ■ Cup...

Open the catalog to page 6

New Hydraulic System A choice of two hydraulic modes optimizes hydraulic performance in all working configurations by preventing interference during simultaneous operations. In Mode 1, designed for crane operations, one pump drives the main hoist and auxiliary hoist winches and the other pump hoists the boom winch. In Mode 2, designed for tower specifications, one pump drives the main hoist winch and the second Mode 1 (Crane operation) Boom pump drives the auxiliary Aux. hoist Main hoist (Tower jib hoist) hoist winch Engine (for hoisting Pump Pump the tower jib) and hoists the Mode 2 (Tower...

Open the catalog to page 7

No compromise in KOBELCO’s safety policy Reliable Safety Features Two-Stage System to Prevent Boom and Jib Over-Hoists With primary and secondary over-hoist prevention devices, this new safety system can prevent boom overhoist at two stages. The primary stop function is activated when the boom or tower approaches the critical angle-toground during hoisting. This new system monitors the angle-to-ground of the boom, tower or jib with a sensor, and swiftly alerts the operator of danger. For the tower, the angle-to-machine is also monitored at this stage. The secondary stop function uses a...

Open the catalog to page 8

Efficient Transportability and Assembly ■The base machine, with boom base attached, has a transport weight of less than 50 tons. ■Horizontally stacked counterweights are easy to assemble/disassemble and transport. ■Boom can be easily assembled with cantilever style up to a length of 36.6m. ■Intermediate support cables are not reguired for boom self-erection. ■Double-tapered pins for boom base enable the boom to be safely assembled/disassembled from the outside. ■The upper spreader storage guides make it easy to connect guy cables. ■Gantry raising/lowering cylinder, as standard equipment,...

Open the catalog to page 9

For better man-machine communication Multi-Function LMI Display The newly designed load moment indicator (LMI) system features a large, easy-to-read LCD display. The rated load, actual load, load ratio, and other information are displayed in large characters. Warnings and other items are displayed in color, and text messages and alarms alert the operator to prevent dangerous conditions from developing. Other information can also be displayed, including a rated load chart and rated load curve, in addition to a function that regulates the working range. The easy-to-read LCD multi display...

Open the catalog to page 10

Crane Boom Units are SI units. { } indicates conventional units. * Including upper and lower machine, 24.6 ton counterweight, basic boom, hook, and other accessories. ** Base machine with boom base, crawlers, gantry, lower spreader, upper spreader, wire ropes for main and boom hoist winches.

Open the catalog to page 11

■General Dimensions (Unit: mm) ■General Dimensions (Unit: mm) Note: This catalogue may contain photographs of machines with specifications, attachments and optional equipment not certified for operation in your country. Please consult KOBELCO for those items you may require. Due to our policy of continual product improvements all designs and specifications are subject to change without advance notice. Copyright by KOBELCO CRANES CO., LTD. No part of this catalogue may be reproduced in any manner without notice. Inquiries To: 17-1, Higashigotanda 2-chome, Shinagawa-ku, Tokyo 141-8626 JAPAN...

Open the catalog to page 12All Kobelco Cranes Co. catalogs and technical brochures

-

SK10SR

8 Pages

-

SL6000 G SL4500G

12 Pages

-

CKE G Series, BME G Series

28 Pages

-

HEAVY_DUTY_BASE_MACHINES

6 Pages

-

BMS800spec

20 Pages

-

CK1600G-2

70 Pages

-

CKE900G-3spec

24 Pages

-

CKS800

24 Pages

-

TK750G

16 Pages

-

7055

24 Pages

-

CK90UR, CK120UR

2 Pages

-

CKE1350G

15 Pages

-

CKE-BME series

15 Pages

-

RKE 450

4 Pages

-

RK250

4 Pages

-

7120SFS

28 Pages

-

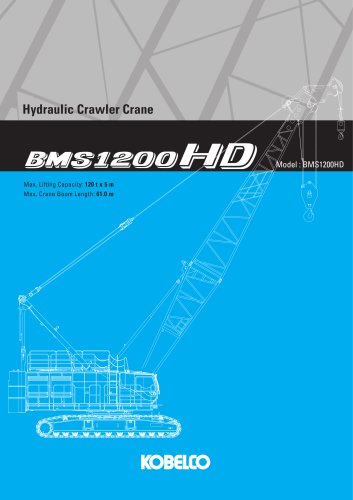

BMS1200HD

24 Pages

-

SL4500S

56 Pages

-

SL4500G

29 Pages

-

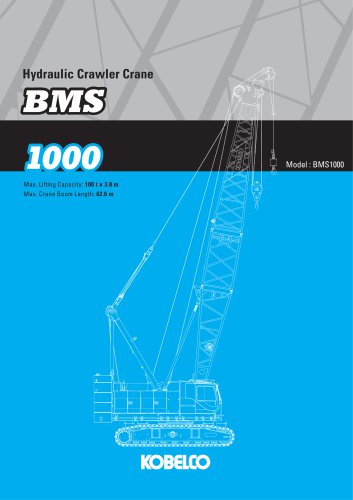

BMS1000

20 Pages

-

CKS2500

88 Pages

-

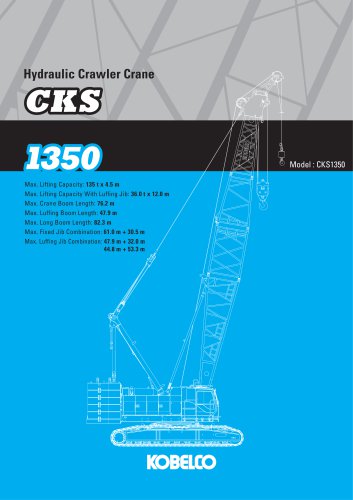

CKS1350

48 Pages

-

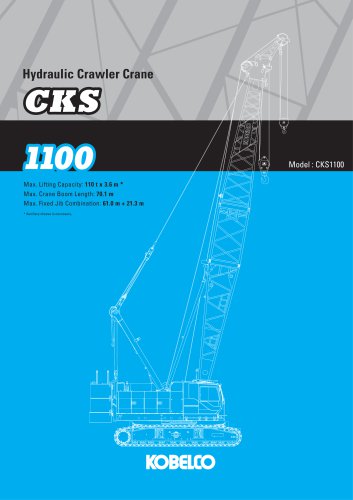

CKS1100

28 Pages

-

CKS900

28 Pages

-

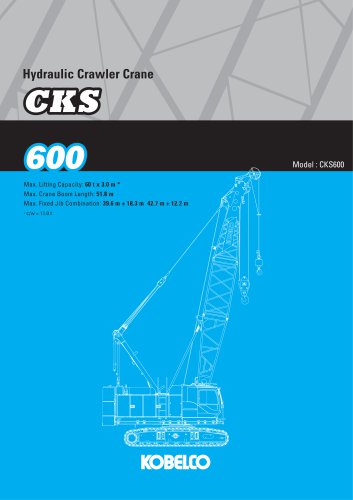

CKS600

24 Pages

-

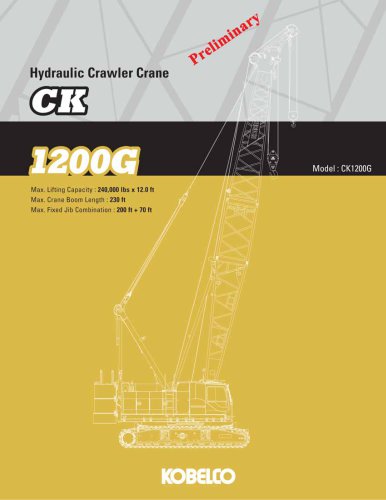

CK1200G

24 Pages

-

CKE2500G

84 Pages

-

BME800G

20 Pages

-

CKE1100G

24 Pages

-

CKE900G

24 Pages

-

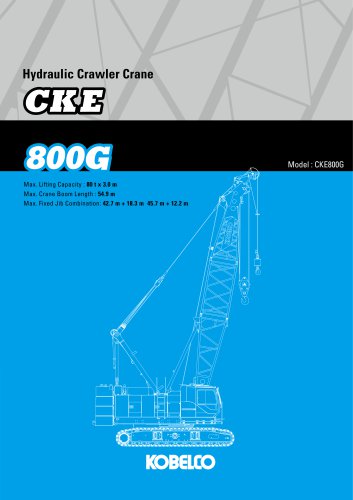

CKE800G

24 Pages

-

CKE600G

20 Pages

-

MK500

3 Pages

-

CKE600 - CKE700

4 Pages

-

TK Series

8 Pages

-

CK series

14 Pages

-

SL series

12 Pages

-

CKGS series

14 Pages

-

CKS-BMS-7000S series

28 Pages