Catalog excerpts

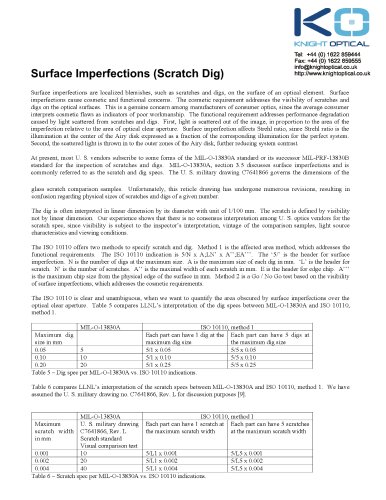

Surface Imperfections (Scratch Dig) OPTICAL Tel: +44(0)1622859444Fax: +44(0)1622859555info@knightoptical.co.uk http ://www.kn ig htoptica I .co. u k Surface imperfections are localized blemishes, such as scratches and digs, on the surface of an optical lment. Surface imperfections cause cosmetic and functional concerns. The cosmetic requirement addresses the visibility of scratches and digs on the optical surfaces. This is a genuine concern among manufacturer s of consumer optics, since the average consumer interprets cosmetic flaws as indicators of poor workmanship. The functional requirement addresses performance d驩gradation cause d by light scattered from scratches and digs. First, light is scattered out of the image, in proportion to the area of the imperfection relative to the area of optical clear aperture. Surface imperfection affects Strehl ratio, since Strehl ratio is the illumination at the center of the Airy disk expressed as a fraction of the corresponding illumination for the perfect System. Second, the scattered light is thrown in to the outer zones of the Airy disk, further reducing System contrast. At prsent, most U. S. v endors subscribe to some form s of the MIL-O-13830A standard or its suc ces s or MIL-PRF-13830B standard for the inspection of scratches and digs. MIL-O-13830A, section 3.5 discusses surface imperfections and is commonly re ferre d to as the scratch and dig specs. The U. S. military drawing C7641866 governs the dimensions of the glass scratch comparison samples. Unfortunately, this reticle drawing has undergone numerous revisions, resulting in confusion regarding physical sizes of scratches and digs of a given number. The dig is often interpreted in linear dimension by its diameter with unit of 1/100 mm. The scratch is defined by visibility not by linear dimension. Our exprience shows that there is no consensus interpr驩tation among U. S. optics v endors for the scratch spec, since visibility is subject to the inspector's interprtation, vintage of the comparison samples, light source characteristics and viewing conditions. The ISO 10110 offers two methods to specify scratch and dig. Method 1 is the affected area method, which addresses the functional requirements. The ISO 10110 indication is 5/N x A;LN' x A";EA"\ The '5/' is the header for surface imperfection. N is the number of digs at the maximum size. A is the maximum size of each dig in mm. 'L' is the header for scratch. N' is the number of scratches. A" is the maximal width of each scratch in mm. E is the header for edge chip. A'" is the maximum chip size from the physical edge of the surface in mm. Method 2 is a Go / No Go test based on the visibility of surface imperfections, which addresses the cosmetic requirements. The ISO 10110 is clear and unambiguous, when we want to quantify the area obscured by surface imperfections over the optical clear aperture. Table 5 compares LLNL's interprtation of the dig specs between MIL-O-13830A and ISO 10110, method 1. MIL-O-13830A ISO 10110, method 1 Maximum dig Each part can have 1 dig at the Each part can have 5 digs at size in mm maximum dig size the maximum dig size 0.05 5 5/1 x 0.05 5/5 x 0.05 0.10 10 5/1 x 0.10 5/5x0.10 0.20 20 5/1 x 0.25 5/5 x 0.25 Table 5 - Dig spec per MIL-O-13830A vs. ISO 10110 indications. Table 6 compares LLNL's interpr驩tation of the scratch specs between MIL-O-13830A and ISO 10110, method 1. We have assumed the U. S. military drawing no. C7641866, Rev. L for discussion purposes [9]. MIL-O-13830A ISO 10110, method 1 Maximum scratch width in mm U. S. military drawing C7641866, Rev. L Scratch standard Visual comparison test Each part can have 1 scratch at the maximum scratch width Each part can have 5 scratches at the maximum scratch width 0.001 10 5/L1 x 0.001 5/L5 x 0.001 0.002 20 5/L1 x 0.002 5/L5 x 0.002 0.004 40 5/L1 x 0.004 5/L5 x 0.004 Table 6 - Scratch spec per MIL-O-13830A vs. ISO 10110 indications.

Open the catalog to page 1All Knight Optical (UK) Ltd catalogs and technical brochures

-

Knight Optical Brochure

6 Pages

-

MIL-G-174B Optical Glass

16 Pages

Archived catalogs

-

POL-HN22 - HN22 Polariser

1 Pages

-

POL-HR - HR Sheet polariser

1 Pages