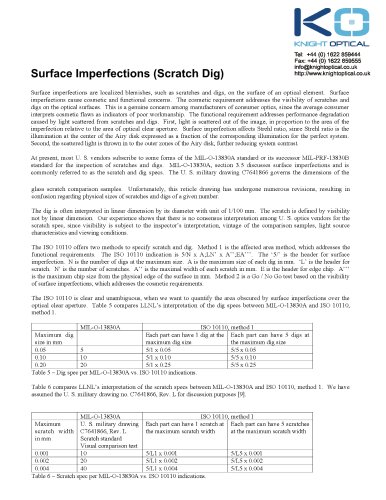

Catalog excerpts

MIL-S-174B 5 December 1986 SUPERSEDING MIL-G-174A 5 November 1963 MILITARY SPECIFICATION GLASS, OPTICAL This spcification is approved for use by ail Departments and Agencies of the Department of Dfense. 1. SCOPE 1.1 Scope. This sp驩cification establishes the requirements for optical glass to be used in the fabrication of optical lments. Requirements for sp驩cial, class 2 (nonstandard), glass will be in accordance with the contract or purchase order. 1.2 Classification. Optical glass shall be of the following classes, grades, and forms (see 6.2): Class 1 - Standard Class 2 - Spcial Grades - A, B, C, D (striae content) Forms - Plates, slabs, formed pressings. 2. APPLICABLE DOCUMENTS 2.1 Government documents. 2.1.1 Spcifications, standards and handbooks. Unless otherwise specified, the following sp驩cifications, standards, and handbooks of the issue listed in that issue of the Department of Dfense Index of Spcifications and Standards (DoDISS) specified in the solicitation form a part of this sp驩cification to the extent specified herein. SPECIFICATIONS FEDERAL PPP-B-601 - Boxes, Wood, Cleated Plywood. PPP-B-621 - Box, Wood, Nailed and Lock-Corner. PPP-B-636 - Box, Shipping, Fiberboard. PPP-C-1752 - Cushioning Material, Packaging, Unicellular Polyethylene Foam, Flexible. PPP-C-1797 - Cushioning Material, Rsilient, Low Density, Unicellular, Polypropylene Foam. Bn驩ficiai commente (recommendations, additions, deletions) and any pertinent data which may be of use in improving this document, should be addressed to: Commander, US Army Armament, Research and Development Center, ATTN: SMCAR-ESC-AS, Dover, New Jersey 07801-5001 by using the self-addressed Standardization Document Improvement Proposai (DD Form 1426) appearing at the end of this document or by letter.

Open the catalog to page 1

MUi-G174B MILITARY MILח P116 - Prשservation, Methods of. MIL-0-15830 - Optical Components for Pire Control Instruments; General Spcification Governing the Manufacture, Assembly and Inspection of. MIL-P-17667 - Paper, Wrapping, Chemically Neutral (Noncorrosive). MLL-I-45208 - Inspection Systems Requirements. STANDARDS MILITARY MLL-STD-105 - Sampling Procdures and Tables for Inspection by Attributes. MIL-STD-129 - Marking for Shipment and Storage. MIL-STD-2073 - DoD Material Proc驩dures for Development and Application of Packaging Requirements. 2.1.2 Other Government documents. The following...

Open the catalog to page 2

MIL-G-174B 3- REQUIREMMTS 3.1 Materials. Materials used shall be capable of producing optical glass which conforas to the requirements for type, grade, and forra as detailed in this spcification and as specified by the applicable contract or purchase order (see 6.2). 3.1.1 Color. Optical glass shall be free of color to the extent that a standard white target shall appear unchanged in color when viewed through a thickness of 2 centimeters of ail glasses having an index of refraction to 1.60 or less in the 589«3 nanometer (nm) sodium D line. The glass may appear slightly yellow or slightly...

Open the catalog to page 3

MIL-G-174B 3.3*5 Abbe constant. Standard glass shall have the Abbe constant correctly identified to the first dcimal place, and shall conform to the nominal value specified in the contract within the following tolrances: below 30, + 0.2; from 30 to 45, + 0.3, between 45 and 55, + 0.4; over 55, + 0.5- 3.3*6 Partial dispersions. Standard glass shall conform to the partial dispersion values specified in the contract. 3.3.7 Strain. Distribution of permanent strain in standard glass shall be symmetrical, and the bir驩fringence resulting from permanent strain shall not produce more than 10...

Open the catalog to page 4

MLL-G-174B TABLE I. Inclusions vs. cross-section area. Inclusion no. Maximum total cross-sec. area mm2/l00cm3 Maximum size diameter millimeter (mm) Minimum size diameter millimeter (mm) 0 0.03 0.20 0.06 1 0.12 0.39 0.06 2 0.25 0.57 0.06 3 0.50 0.80 0.06 5 0.20 0.05 0.02 10 0.80 0.10 0.03 15 1.80 0.15 0.05 20 3-15 0.20 0.05 30 7-10 0.30 0.10 40 12.60 0.40 0.10 50 19.70 0.50 0.10 3.3-11 Finish. Laps, folds, stones and fire cracks on formed pressings shall not be deeper than one-half the grinding stock specified in the applicable drawing or as detailed in table II, and shall not be so...

Open the catalog to page 5

MTL-G-174B 3- 3>12 Form. Class 1 optical glass shall be supplied to the fora specified in the contract. 3-3'12.1 Plates or slabs- Optical glass of this form shall be flat and reasonably square or rectangular, with sides not ]ess than 50 mm or greater than 304 mm thick. If the width is no greater than 160 mm, then length up to 575 mm shall be pennitted. 3.3*12.1.1 Dimensions. Optical glass in the form of plates or slabs shall have the thickness specified in the contract within the following tolrances: up to and including 20 mm thick, minus 0 to 2 mm; over 20 mm thick, minus 0 to plus 4....

Open the catalog to page 6

MTL-G-174B accordance with the requirements of MIIi-I-45208 and MIL-0-13830. 4.2 Inspection provisions. 4.2.1 Inspection lot. Unless otherwise specified by the contracting officer, inspection lot size, formation, and prsentation of lots shall be in accordance with "Submission of Product" as defined in MIL-STD-105- Optical glass produced by the pot method shall be considered a lot resuit ing from each melt and annealing. When a lot is not identifiable from a melt, or the optical glass is produced by the continuous process, the lot shall not consist of more than 500 pounds of material offered...

Open the catalog to page 7

MEL-G-174B TABLE III. Requirements and tests Characteristics Requirement Test procdure Materials 3.1 Visual Color 3.1.1 4-4-1 Absorption 3-1.2 4.4.2 Radioactive material 3.1-3 4-4-10 Class requirements 3.2 Visual Type name and number 3-3-2 and 3-3.3 Visual Index of refraction 3-3-4 4-4-3 Abbe constant 3.3-5 4.4.4 Partial dispersions 3-3.6 4.4-4-1 Strain , 3-3-7 4.4.5 Striae (Grades A, B, C, and I Required samples (standards) ) 3-3-8.1 to 3-3.8.4 4.4.6 3.3.9 and 6.2 4.4.7 Inclusions 3.3.10, 3.3-10.1,and 3.3-10.2 w/table I 4.4-8 Finish 3.3.11 (w/table II) 4.4.9 Form 3-3.12 Per contract Plates...

Open the catalog to page 8

MIL-G-174B 4.2.2.4 Disposition of nonconforming product. Rejected lots shall be screened for ail defective characteristics. Removal or correction of defective units and resubmittance of rejected lots shall be in accordance with "Acceptance and Rejection" as specified in MIL-STD-105- 4.3 Inspection equipment. Except as otherwise provided in the contract, the contractor shall furnish and maintain ail required measuring and testing equipment in accordance with the "Inspection Equipment" requirement of MIL-I-45208. The Government reserves the right to use the test equipment for its own...

Open the catalog to page 9All Knight Optical (UK) Ltd catalogs and technical brochures

-

Knight Optical Brochure

6 Pages

Archived catalogs

-

POL-HN22 - HN22 Polariser

1 Pages

-

POL-HR - HR Sheet polariser

1 Pages