Catalog excerpts

System solutions from KML

Open the catalog to page 1

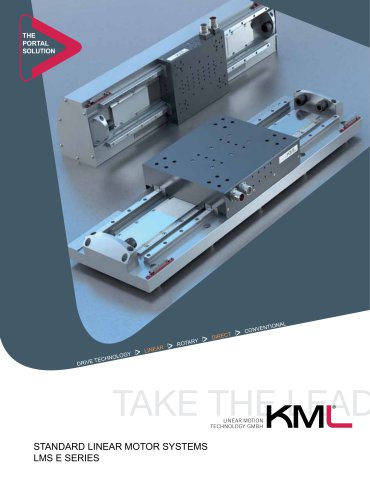

Standard and individual solutions ENTER A WORLD OF DYNAMICS AND PRECISION: All standard linear motor systems and torque motors can also as a competent, experienced and professional partner it is our task be combined to form multiple axis solutions with plug-in energy to fulfil your individual needs and to satisfy the high requirements chains, cables and controls. With our drive and control electronics for dynamics, precision, operating efficiency and reliability. you can create the perfect solution for virtually unlimited applica- As a leading innovation specialist for complex linear motor...

Open the catalog to page 2

LMS E2 series The LMS E2 series was developed specifically as alternative for conventional drive systems such as tooth belts or ball screw driven axles. The LMS E2 series is designed for highly dynamic movements of small to medium loads. The compact and simple design not only make these linear motor systems economical, they are also well suited for extremely tough conditions. Features: • Different sizes and performance ratings • Measuring system resistant to contamination • Rigid design • Maximum dynamics • Protection class IP65 optional • Clean room design optional • Absolute linear...

Open the catalog to page 3

LMS V series The LMS V series was specifically developed for vertical applications and for moving small to medium loads. The compact and rigid design also maintains a permanent high degree of positioning accuracy at accelerated dynamics. The desired position can be maintained reliably only by the optional use of a weight compensation and a brake system. Features: • Different sizes and performance ratings • Suitable for vertical applications • Compact design • Maximum dynamics • Optimized stroke (max. 400 mm) • Mass balancing • Pneumatic holding brake Fields of application: • Pick & place •...

Open the catalog to page 4

Torque motors, RDD series The developed torque motors are equipped with a fixed or moving hollow shaft and offer an extremely high performance spectrum. Constant precise movements and positions can be achieved at high continuous and peak torque in combination with high rotary speeds. Features: • Different sizes and performance ratings • Suitable for high speed rotation (several 1000 min-1) • High torque • Compact design • High absolute accuracy and repeatability • Precise running performance Fields of application: • Indexing tables • Winder drives • Grinding spindle drives • Precision...

Open the catalog to page 5

ACCESSORIES All standard systems can be supplied with appropriate accessories on request. • Rigid support design • Mounting accessories • Energy chains • Plug-in cables and connectors • Servo drives • Motion controllers SERVICES All systems are subjected to a 100% functional check prior to delivery. For complete motion systems, a set of parameters is supplied for quick and simple start-up. If requested, defined movements are simulated and documented. Measurement and documentation of the system's precision via laser interferometer is possible. For positioning applications in the sub-µm...

Open the catalog to page 6

CUSTOMIZED SOLUTIONS To meet specific customer requirements not covered by the standard program, perfectly customized solutions are developed in close High quality, speedy and reliable machine start-up cooperation with the customer. • Factory start-up • Customer specific tests with documentation A broad knowledge base for individual requirements in: • mechanical engineering • electrical engineering Always reliably up to date • measuring technology • control and drive technology • On-site customer start-up Design and development Long-standing experience in the implementation of individual...

Open the catalog to page 7

KML Linear Motion Technology GmbH Headquarters Daumegasse 1–3, A-1100 Vienna Telephone: +43 1 641 50 30-0 Fax: +43 1 641 50 30-50 E-Mail: office@kml-technology.com www.kml-technology.com For all further subsidiaries and contacts, please refer to our website: www.kml-technology.com/en/contact Subject to technical modifications for progress purposes and printing errors. Although this publication has been produced with great care with the purpose of providing information as complete as possible, KML Linear Motion Technology GmbH does not assume any liability for damages arising directly or...

Open the catalog to page 8All KML Linear Motion Technology GmbH catalogs and technical brochures

-

LMS E

11 Pages

-

LMS E2

2 Pages

-

LMS V

2 Pages

-

product overview

4 Pages

-

Image Brochure

16 Pages

-

KML Image

16 Pages

-

System Solutions from KML

8 Pages

Archived catalogs

-

IKO TU Units

62 Pages

-

C-Lube Linear Way

155 Pages

-

LineTech LM

44 Pages

-

Line Tech PS

68 Pages