Catalog excerpts

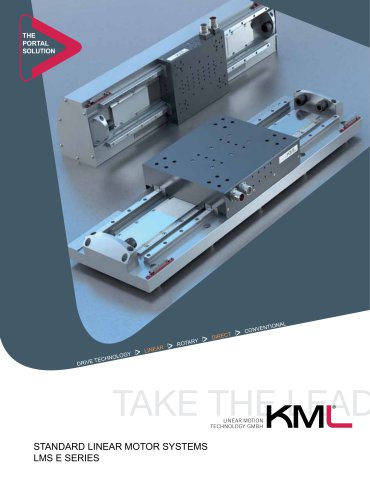

Product description LMS E2 The LMS E2 series was developed specifically as alternative for conventional drive systems with tooth belts or ball screws. The LMS E² series is designed for highly dynamic movements of small to medium loads. Owing to their compact and simple design, the linear motor systems of the LMS E² series are both highly suited for price-sensitive applications as well as for very tough environmental conditions. They are also ideally suited for stacked XY- and gantry systems. Areas of application include automation technology, the packaging industry as well as the automotive industry and many others. Owing to its rigid design, the LMS E² series is also highly suited for applications in the printing, textile, food and pharmaceutical industries. Basically, the LMS E² series is used wherever maintenance-free high dynamics are required and where the conditions require robust mechatronics and good pricing. • Encoder system with various output signals, • Rigid design • Maximum dynamics • Absolute linear encoder system optional • Clean room design optional • Limit switch optional • IP65 optional

Open the catalog to page 1

W Stop positions Reference mark Nominal stroke Dimensions: Size Total length L [mm] = S + LT + 2 x (LL + 5) Available nominal strokes S [mm] Technical Data: Size Headquarters Daumegasse 1–3, A-1100 Vienna Telephone: +43 1 641 50 30-0 Fax: +43 1 641 50 30-50 E-mail: office@kml-technology.com www.kml-technology.com For all further subsidiaries and contacts, please refer to our website: www.kml-technology.com/en/contact Authorised KML-Partner

Open the catalog to page 2All KML Linear Motion Technology GmbH catalogs and technical brochures

-

LMS E

11 Pages

-

LMS E2

2 Pages

-

LMS V

2 Pages

-

product overview

4 Pages

-

Image Brochure

16 Pages

-

System solutions from KM

8 Pages

-

KML Image

16 Pages

-

System Solutions from KML

8 Pages

Archived catalogs

-

IKO TU Units

62 Pages

-

C-Lube Linear Way

155 Pages

-

LineTech LM

44 Pages

-

Line Tech PS

68 Pages