Catalog excerpts

Standard linear motor systems LMS M series

Open the catalog to page 1

Standardized connector interface for customer’s cabling Absolute linear encoder system Mass balancing Integrated cable routing LMS M Production quantity: IMPROVE The combined LMS M linear motor system has two crosswise Process quality: IMPROVE axes that are directly connected to each other for mass opti- Machine uptime: IMPROVE mization purposes. The very compact and integral design with Energy efficiency: IMPROVE inherent stability is suitable for both vertical applications (Z/Y axes) and horizontal compound table applications (X/Y axes). These are some arguments for replacing existing...

Open the catalog to page 2

Linear motor system LMS M: multifunctional Cycle time of 0.35 s = highest productivity Cost efficiency in two axes Characteristics: • High speed pick & place • Absolute linear encoder system* • High speed assembly • Pneumatic weight compensation* • Brake system* • Test units (permanent test benches) • Lifetime lubrication • Cycle type systems • Cleanroom version* • Feeding systems • Flexible interface connection • Compound table applications • Tool connector* • Connector interface • Flexible controller options • Attractive price/performance ratio * optionally available Advantages of the LMS...

Open the catalog to page 3

Technical data Z stroke (vertical): Positioning accuracy: Feedback signals: Protection class: Relubrication interval: Installation positions: Weight compensation: mechanic, pneumatic, magnetic 160 140 Fahrzeit [ms] Move time [ms] Fahrzeit [ms] Move time [ms] Fahrzeit [ms] Move time [ms] Masse = 2kg Load Load Masse = 4kg Load Masse = 8kg Masse = 2kg Load Masse = 4kg Load Load Masse = 8kg

Open the catalog to page 4

Nominal stroke = S Nominal stroke Reference mark Stop positions Z-axis Ws Wt Y axis Stop positions Reference mark Nominal stroke Dimensions: Size Available nominal strokes Y axis SY [mm] M-10D Available nominal strokes Z axis SZ [mm] 300 Technical data: Size Continuous feed force [N] Peak feed force [N]

Open the catalog to page 5

LMS Linear motor system

Open the catalog to page 6

Corrosion protection S Limited corrosion protection • Exposed aluminum components: anodized • Steel components: bright or gun metal finished • Sheet metal components: stainless steel • Guiding system: normal steel C Extensive corrosion protection • aluminum components: anodized All • Steel components: stainless steel • Sheet metal components: stainless steel • Guiding system: stainless steel or coated Cleanroom version upon request A09 Output signal, encoder pitch and signal period of the linear encoder system Table 5 Output signal A01 A02 A03 Encoder pitch Signal period Accuracy class of...

Open the catalog to page 7

Position of the reference point LR0 Without reference point LR1 10 mm before the negative limit switch LR2 In the center of the stroke LR3 10 mm before the positive limit switch LRS Reference point position according to customer's request LS0 Limit switch LS0 Without limit switch LS1 PNP break function on both sides SB0 LSS Special limit switch type to be defined by the customer Holding brake SB0 Without holding brake SBS Spring-activated holding brake, opening pneumatically Weight compensation GC0 Without weight compensation GCS Weight compensation by means of a spiral spring GCP Weight...

Open the catalog to page 8

Please fax to: +43 1 641 50 30-51 Design specification linear motor handling Y/Z Customer Postal code, town Symbol Process data Installation position Operating time/day Desired service life Process data Dwell time Load cycles/minute Motion profile Customer mass in motion Press-in forces Feedback (abs./incr.) Holding brake Mass balancing Periphery Ambient temperature Cleanroom class Supply voltage Annual requirement Target price Process/gripper time t =______sec 9 Process/gripper time t =______sec

Open the catalog to page 9

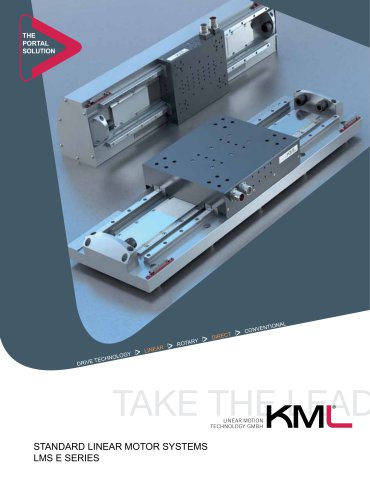

Standard linear motor systems and torque motors, RDD series Standard linear motor systems Dynamic, precise, plug & play, providing low maintenance The torque motors of the RDD series are provided with a and process safety: Our standard linear motor systems hollow shaft, either stationary or movable as required, and have a very high power density. This permanently ensures been designed to enable accurate and highly dynamic posi- precise motion and positioning even with high continuous or tioning of a wide range of loads. peak torques combined with high speeds. The standard version includes...

Open the catalog to page 10

Multi-axis solutions and individual customized solutions All linear motor systems and torque motors also possible as multi-axis solutions Individual customized solutions All standard linear motor systems and torque motors can also range, we develop individual, tailor-made solu- Anything is possible: In addition to the extensive standard be combined to form multi-axis solutions with energy chains, tions, precisely optimized with respect to cables and conductors ready to plug in. This fact makes them your requirements in order to accom- perfectly suitable for almost unlimited applications....

Open the catalog to page 11

with confidence & certainty. Absolute reliability to increase your compe- oriented technology. Consistently pursuing this goal, titiveness: For approximately 20 years, we have been the name of KML Linear Motion Technology is associated with developing, producing and distributing high-quality, innovative competence, innovation and reliability by our customers. system solutions. Our aim is to meet your individual needs and to fulfil and even exceed your personal requirements. Experience provides confidence. In this spirit, we make a significant contribution to your success, allowing both of...

Open the catalog to page 12

KML Linear Motion Technology GmbH Headquarters Daumegasse 1–3, A-1100 Vienna Phone: +43 1 641 50 30-0 Fax: +43 1 641 50 30-50 E-mail: office@kml-technology.com www.kml-technology.com For all further subsidiaries and contacts, please refer to our website: www.kml-technology.com/en/contact Subject to printing errors and technical modifications serving the progress. Although this publication has been composed with great care with the purpose of providing information as complete as possible, KML Linear Motion Technology GmbH does not assume any liability for damages arising directly or...

Open the catalog to page 14All KML Linear Motion Technology GmbH catalogs and technical brochures

-

LMS E

11 Pages

-

LMS E2

2 Pages

-

LMS V

2 Pages

-

product overview

4 Pages

-

Image Brochure

16 Pages

-

System solutions from KM

8 Pages

-

KML Image

16 Pages

-

System Solutions from KML

8 Pages

Archived catalogs

-

IKO TU Units

62 Pages

-

C-Lube Linear Way

155 Pages

-

LineTech LM

44 Pages

-

Line Tech PS

68 Pages