Catalog excerpts

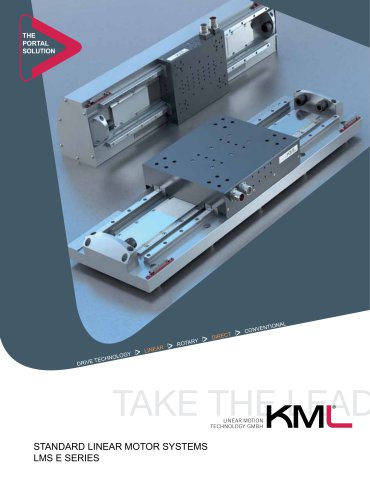

Standard linear motor systems Lms e series

Open the catalog to page 1

Combination options LMS E – Reliability plus dynamics The linear motor system of the LMS E series was developed The standardized leveling elements enable simple and A special feature of the LMS E series is the versatile single axes. This allows the realization of numerous single specifically for applications requiring high dynamics, main- secure alignment of the linear motor systems on unmachined combination of the individual linear motor axes. Both the and multiple axis solutions, such as cross tables or portal tenance-free operation and robust mechatronics. Available machine frames....

Open the catalog to page 2

High rigidity high performance density The linear axes of the LMS E series are characterized by incomparable rigidity and accustomed high dynamics and precision. The motor is moulded in the slide and provides high performance density, i.e. low mass at high feeding force. LMS E – efficiency in detail The LMS E series offers numerous variants and options to meet customized requirements at the best price/performance ratio. 800VDC BUS voltage Robust details increase overall machine performance and suitability for the various sectors of industry. All the benefits of linear motor technology -...

Open the catalog to page 3

advantages / customer benefits of the linear motor system LMS e series Economy and High Precision design: High dynamics and precision at an attractive • Allows using one series for a wide range price/performance ratio: • Increased output at the price of conventional drive solutions Rigidity-optimized cross-beam profile: • Short settling times Maintenance-free for five years or 20,000 km: • Shorter cycle times • High machine uptime • Low operating costs Supported or self-supporting mounting options: • Additional support is not required • Space-saving Open drive interface: • Use of...

Open the catalog to page 4

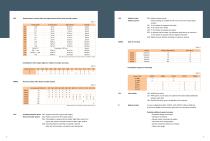

Basic / portal axis LMS E 19 BR * Base plate in plate design (e.g. for cross table mountings or horizontal single axes) Base plate in beam version (e.g. for portal mountings or standing single axes) Series / Size Series / Size * The values in brackets refer to systems with protective steel coverings. Further sizes are planned. * The values in brackets refer to systems with protective steel coverings. Further sizes are planned. Nominal stroke (standard stroke, also see table 10) [mm] LL Length of end stop system with elastomer dampers (ES084) [mm] LL Length of end stop system with hydraulic...

Open the catalog to page 5

Type code KML standard linear motor systems LMS E Continuous force of a slide Table 8 Power type code Series / Size The type code of the KML linear motor systems is explained using an example. Example: LMSE-19BRL.EB.P.N.0300A.X.S1.00500.S.A01.P0050.CD1.LR1.ES030.LS1 A LMS Linear motor system Cooling type Convection cooling using ambient air WM Water cooling of motor (in progress) E-19BRL Mounting of system is directly over the basis area of the base plate. Mounting of the system is directly over the basis plate of the beam. Mounting of the system is via leveling elements in the base Winding...

Open the catalog to page 6

Output signal, encoder pitch and signal period of the linear encoder system Output signal Encoder pitch Signal period LR1 10 mm before the negative limit switch LR3 10 mm before the positive limit switch LR4 In systems with two slides, one reference point each at an interval of 10 mm before the positive and the negative limit switch LRS Reference point position according to customer's request Type of end stop Table 14 Combination of the output signal in relation to system accuracy Table 12 System accuracy Combination options of end stops Accuracy class of the linear encoder system Only this...

Open the catalog to page 7

Modular design for your solution kML standard linear motor systems of the LMS E series The package of options includes a wide range of energy can be used both as single axes or as multiple axis chains, cables, drives and control electronics. systems in combination with the systems of other standard series. The LMS E series can be adapted individually to Our employees will advise you in every concrete case, from prevailing requirements by utilizing the varied offer of simple to complex solutions. accessories and extension components. ACCESSORIES All standard systems can be supplied with the...

Open the catalog to page 8

take the lead through innovation. KML sets new standards for simple as well as complex, Our high quality standard is assured by our demand for the dynamic and precise assembly group solutions with linear best employees, process stability and operational reliability. and rotary drive axes. Due to our long experience we can look back on many successful standardized and individual Take the lead - with innovation & passion. system solutions. CUSTOMIZED SOLUTIONS To meet specific customer requirements not covered by our standard program, perfectly customized solutions are developed in close...

Open the catalog to page 9

with confidence & certainty. Absolute reliability to increase your competi- Consistently pursuing this goal, the name of KML Linear tiveness: For nearly 20 years, we have been developing, Motion Technology is associated with competence, innovation producing and distributing high-quality, innovative system solutions. Our aim is to meet your individual needs and to fulfil and even exceed your personal requirements. Experience provides confidence. In this spirit, we make a significant contribution to your success, allowing both of us Confidence, fairness and certainty are our basic values when...

Open the catalog to page 10

KML Linear Motion Technology GmbH Headquarters Daumegasse 1–3, A-1100 Vienna Telephone: +43 1 641 50 30-0 Fax: +43 1 641 50 30-50 E-mail: office@kml-technology.com www.kml-technology.com For all further subsidiaries and contacts, please refer to our website: www.kml-technology.com/en/contact Subject to technical modifications serving the progress and printing errors. Although this publication has been composed with great care with the purpose of providing information as complete as possible, KML Linear Motion Technology GmbH does not assume any liability for damages arising directly or...

Open the catalog to page 11All KML Linear Motion Technology GmbH catalogs and technical brochures

-

LMS E2

2 Pages

-

LMS V

2 Pages

-

product overview

4 Pages

-

Image Brochure

16 Pages

-

System solutions from KM

8 Pages

-

KML Image

16 Pages

-

System Solutions from KML

8 Pages

Archived catalogs

-

IKO TU Units

62 Pages

-

C-Lube Linear Way

155 Pages

-

LineTech LM

44 Pages

-

Line Tech PS

68 Pages