Catalog excerpts

Features of Precision Positioning Table TU 1 2 3 Extra rigid U-shaped track rail is adopted. 4 Lubrication part C-Lube plate can be applied. By adopting a U-shaped track rail, the rigidity of the track rail under moment load and torsion is greatly increased. Abundant sizes precision positioning Table TU comes in eight sizes, with a track rail width ranging from 25 mm to 130 mm. Abundant options The type and lead of ball screw, motor type, sensor installation specifications, surface treatment specifications, bellows specification, etc. can be selected. Thus, Positioning Table TU can be used...

Open the catalog to page 3

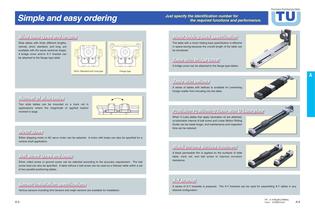

Precision Positioning Table Simple and easy ordering Just specify the identification number for the required functions and performance. TU The table with a motor folding back specification is effective in space-saving because the overall length of the table can be shortened. Slide tables with three different lengths, namely, short, standard, and long, are available with the same sectional shape. A bridge cover and /or X-Y bracket can be attached to the flange type table. A bridge cover can be attached to the flange type tables. Short, Standard and Long type Flange type A series of tables...

Open the catalog to page 4

Identification Number and Specification Size Example of identification number 3 Table size For applications, see Table 1. TU 86 FG 89 A / Y029 G 10 S 0 0 R Q Table 1 25, 30, 40, 50, 60, 86, 100, 130 Combination of slide table shapes and sizes Shape Model TUC TU S TU G TUFC TUF TU FG TUYF TUES TU EF TU 25 Type TU 30 1 Model TU 40 2 Slide table shape TU 50 TU 60 Size TU 86 3 Size TU100 TU130 Part code Part code 4 Track rail length 4 Track rail length 5 Number of slide tables For applications, see Table 2.1, Specify the track rail length in cm. and Table 2.2. Motor code 5 Number of slide...

Open the catalog to page 5

Electric Device Motor code No symbolWithout motor A With motor 7 Motor type For applications, see Table 3. Type of motor 6, When Without motor no symbolis selected in item Motor attachment and coupling applicable to the selected motor are mounted at delivery. When Motor attachment and coupling are not necessary, please specify No symbol .See specification after C-1 Ball screw specificationsP.A-23 Ball screw code Motor code For applications, see Table 4. 9 Ball screw lead 4, 5, 8, 10, 20, 25 Ball screw leads Ball screw lead Motor brand Motor part number Motor code Model Motor part number...

Open the catalog to page 6

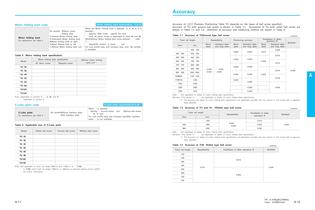

Accuracy Motor folding back specification Motor folding back code 13 Motor folding back For applications, see Table 5 No symbol Without motor folding back U Upward Motor folding back S Downward Motor folding back MMotor folding back to right H Motor folding back to left T Without Motor folding back unit P.A-37 When the Motor folding back is selected U, S, M or H is selected , 6 Specify With motor specify Ain item Only AC servo motor is applicable to sizes 60 and 86. WhenWithout Motor folding back unitis selected code T , 6 and 7 . SpecifyNo symbol in items For Low profile type, and Compact...

Open the catalog to page 7

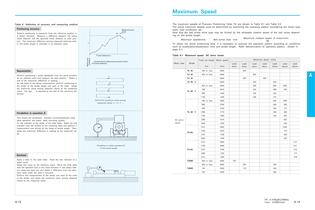

Maximum Speed Table 8 Definition of accuracy and measuring method Positioning accuracy L Perform positioning in sequence from the reference position in a certain direction. Measure a difference between the actual travel distance and the specified travel distance at each position. The maximum difference among measured distances within the stroke length is indicated in an absolute value. Measurement pitch Reference position Travel distance L The maximum speeds of Precision Positioning Table TU are shown in Table 9.1 and Table 9.2. The actual maximum speeds must be determined by examining the...

Open the catalog to page 8

Sensor specification The sensor specification for Precision Positioning Table TU indicates the number of sensors and whether or not a sensor rail for fastening the sensor is attached. Table 17 shows the specifications of sensors. Table 18 shows the specifications of sensor connectors. Note that, when two sensorslimit and three sensorslimit, pre-originare specified in the identification number, sensor will not be wired unless specified. The sectional shape of sensor rail is shown in Fig. 4. The timing charts for the case where the number of sensors is set to 4 are shown in Table 19.1, 19.2,...

Open the catalog to page 17

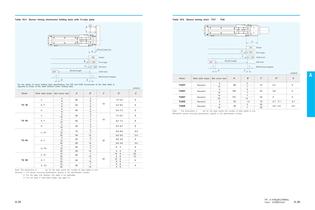

Table 19.4 Sensor timing chartmotor folding back with C-Lube plate Table 19.5 Sensor timing chart TUY TUE CW CCW CCW CW A ON End of track rail A ON C Pre-origin D CCW limit Model C TU 40 S, F G C TU 50 S, F G C, FC TU 60 S, F G, FG C, FC TU 86 S, F G, FG 4 8 4 8 4 8 5 10 5 10 5 10 5 10 20 5 10 20 5 10 20 10 20 10 20 10 20 Note 1The dimensions in are for the case where Remarks 1 For sensor mounting specification, specify in 2 For the table with bellows, this table is not 3 For the code of slide table shape, see page A-35 A 60 60 60 60 60 60 75 94 60 69 60 59 90 60 60 B 2 6 2 6 2 6 3 7 3 7 3...

Open the catalog to page 19

Motor Folding Back Specification C-Lube Plate Specification The motor folding back specification is available for Precision Positioning Table TU. Space can be saved by folding back the motor and reducing the total length of the table. For the motor folding back specification, see the respective dimension tables. Note that the track rail lengths of motor folding back specification are different from these of tables without motor folding back. Table without motor folding back unit is the resultant table after removing the motor folding back unit from the motor folding back table. Table 20...

Open the catalog to page 20

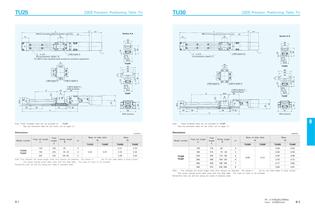

TU25 Precision Positioning Table TU L Minimum center distance between two slide tables in close contact 31 21 h 2 LM TU30 Precision Positioning Table TU Section A-A 67 h L Minimum center distance between two slide tables in close contact 39 2 LM 2 67 Section A-A 20 21 16 2 24 16 9 8.7 30 4-M3 depth 5.5 2 n1-2.9 5 counterbore, depth 2.7 12.4 8 9 24.9 1.8 6.7 1.6 4-M3 depth 4 2 n1-2.9 4.8 counterbore, depth 1.6 For M2.5 cross recessed head screws for precision equipment 25 28 20 14.9 9 12 29.9 TU25S 20 12 43 35 28 TU30S 3.5 22 8 S TU25F 28.6 35 20 A 35 31 L1 20 35 25 46 40 Note Model number...

Open the catalog to page 23

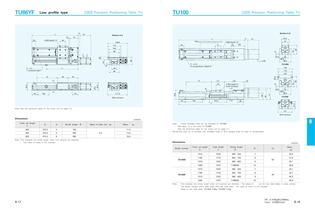

Precision Positioning Table TU Low profile type 13 L 10 35 4-M6 depth 12 LM TU100 Precision Positioning Table TU Section A-A 1 Section A-A 72 L 155Minimum center distance between two slide tables in close contact 46 169.5 L2 45 112 h 3 LM 65.2 3 50 2 4-M8 depth 15 20 100 8 88 52 100 42 68 20 24.5 6 2 n1-9 14 counterbore, depth 9 50 49.5 99.5 TU100S 46 128 86 L1 2 n-7 11 counterbore, depth 7 80 TU86YF 115 102 29.5 87 90 24.5 With sensors 55 153.2 150 A 52 1 3 6 171.5 50 10 130 2-M4 depth 6 both surfaces A 58 100 34 79.5 50 A 111 65.9 32 65.9 S 8 A H 93 84 S 50 49.5 99.5 TU100F 55 61.5 L1...

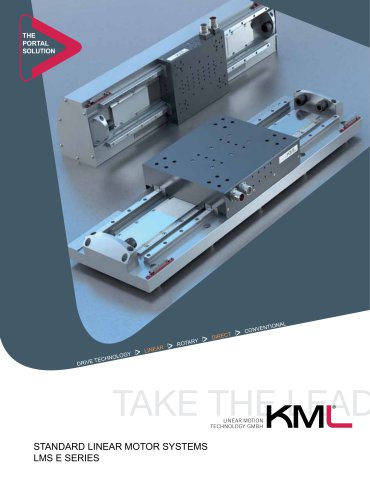

Open the catalog to page 31All KML Linear Motion Technology GmbH catalogs and technical brochures

-

LMS E

11 Pages

-

LMS E2

2 Pages

-

LMS V

2 Pages

-

product overview

4 Pages

-

Image Brochure

16 Pages

-

System solutions from KM

8 Pages

-

KML Image

16 Pages

-

System Solutions from KML

8 Pages

Archived catalogs

-

C-Lube Linear Way

155 Pages

-

LineTech LM

44 Pages

-

Line Tech PS

68 Pages