Catalog excerpts

your global specialist Tribojournal 1 2011 Seaw Worm gears becoming more efficient Optimised friction coefficients for the automotive industry Antiwear layers for rolling bearings

Open the catalog to page 1

Content An eco-friendly alternative Klber Lubrication develops readily biodegradable, non-toxic gear oil for rudder propellers and thrusters 4 Simply more efficient High-performance polyglycol gear oils help increase the efficiency of worm gears and reduce the consumption of resources 8 KlberComp Lube Technology - Gear oils for extreme requirements The perfect match Influence of gear oils on the sealing and friction behaviour of radial shaft seals 12 13 Automotive challenges New lubricant developments amplify design options 18 Reducing operating costs and improving CO2 footprint in the...

Open the catalog to page 2

Push the limits, act sustainably Dear reader Sustainability is a ubiquitous buzzword. There is no doubt: the significance of preserving our environment via careful use of resources cannot be over-estimated. However, I hear more and more comments indicating that people are becoming tired of sustainability as a subject. Talking less and doing more is a great solution to this situation. Kluber Lubrication is doing quite a lot in this regard. We're driven by the question of how we can support you, our customers, in the efficient use, saving and protection of resources. Pushing the limits of...

Open the catalog to page 3

An eco-friendly alternative Kluber Lubrication develops readily biodegradable, non-toxic gear oil for rudder propellers and thrusters All vessels of a certain size today are manoeu-vred by propeller units and thrusters of different designs. Depending on the size of the vessel, these propulsion units may be filled with up to 8,000 litres of oil. During normal operation, oil may leak into the sea through the propeller seals even when they are well-maintained. Oil leakage can also occur due to wear and tear, accidents or faulty handling. While the effect of an individual leakage may be small,...

Open the catalog to page 4

Readily biodgradable lubricants are an option to reduce pollution of the seas Container ships, bulk carriers, harbour tugs and cruise ships have one thing in common: reliable function of their propeller units is essential for their manoeuvrability. This requires reliable sealing of the propeller shaft against the sea as even small quan-tities of water in the lubricating oil can drastically reduce shaft bearing life and cause propeller failure, especially in rudder pro-pellers and thrusters. Special seals are fitted to reliably prevent water from entering the propeller unit. Leakages cannot...

Open the catalog to page 5

Preserving our ecosystems is one of today's major challenges Perfectly matched lubricant and seal contribute to reliable function and prolonged lifetime of gears Major challenges for eco-friendly alternatives Using readily biodegradable gear oils instead of mineral oils is a sizable contribution to preventing pollution of the seas and their inhabitants, as microorganisms can quickly decompose them into carbon dioxide, water and biomass. The biodegradability of mineral oils shown in the OECD 301 F test is approx. 20 %. The new gear oil from Kluber, by comparison, shows a biodegradability of...

Open the catalog to page 6

specianty lubricants for optimum results. Close coopration between manufacturers of lubricants and seals facilittes systematic solutions The result of their cooperation is a tailor-made, environmental-friendly combination of radial shaft seal and lubricant for in-creased reliability and lifetime to reduce costs for downtime and repair. As Klubersynth EG 2-150 is a synthetic oil, its lifetime is three to four times longer than that of mineral oil under compa颭rable operating conditions. As Klubersynth EG 2-150 is miscible with mineral oil, trouble-free changeover to the new oil is possible...

Open the catalog to page 7

Simply more efficient High-performance polyglycol gear oils help increase the efficiency of worm gears and reduce the consumption of resources The increase of gear efficiency harbours a frequently overlooked potential for increas-ing the efficiency of a machine as a whole. A very direct and effective way of increasing power transmission efficiency - which goes along with excellent wear protection - is a changeover from mineral-oil-based to syn-thetic lubricants. Synthetic lubricants, e.g. based on poly-alphaolefin, ester or polyglycol oils, have proven to reduce energy costs and in addition...

Open the catalog to page 8

enormous potential for savings especially in facilities where a large number of gears are operated - for example in logistics centres, filling stations, breweries or air-ports. The example in the box illustrates how several million Euros can be saved at a large airport. Tribological factors are decisive in attaining the maximum performance of a machine and its components. When choosing a lubricant for a gearbox or machine, there-fore, design engineers should be aware of the characteristics of the various types of lubricants and know how to use them. While, as a rule, synthetic special...

Open the catalog to page 9

Fig. 1: Tests performed on Klber Lubrication worm gear test rig: measured weight loss and wear rates Fig. 2: Tests performed on Klber Lubrication worm gear test rig: measured temp鹩ratures and efficiency results Tested and proven Applied to the effect a lubricant provides in worm gears, the aspects of sustainability and energy efficiency can be translated into the wear behaviour and the efficiency of a gearbox. Reduced wear means longer service life of components, which has a con-sequential effect on the exploitation of resources as less raw material is required to make new components to...

Open the catalog to page 10

0,2 Conclusion 0,15 The changeover from mineral-oil-based to synthetic gear oils is a simple and highly effective way of minimising wear and im-proving energy efficiency. The extent of optimisation possible depends on the indi-vidual gear type. Best results are obtained where polyglycol oils are used in worm gears. Additional potential for improvement is offered by polyglycol oils based on special formulations and containing specific additives: such lubricants enable even longer gear and machine life as well as a lower energy consumption for a given output power. 6 0,1 0,06___ 0,04___ O O...

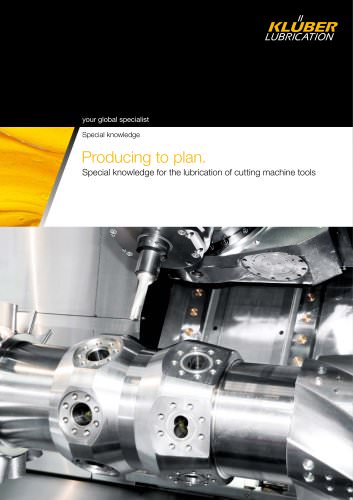

Open the catalog to page 11All Klüber Lubrication catalogs and technical brochures

-

KlueberEfficiencySupport

7 Pages

-

Klübermatic lubricant dispensers

13 Pages

-

Driving with Klüber Lubrication.

15 Pages

-

Geared up for success.

32 Pages

-

All sprays at a glance

2 Pages

-

Bonded coatings

16 Pages

-

Automotive industry

16 Pages

-

Cement industry

2 Pages

-

Seaworthy

24 Pages

-

Pneumatics

24 Pages