Website:

Klüber Lubrication

Website:

Klüber Lubrication

Group: Freudenberg

Catalog excerpts

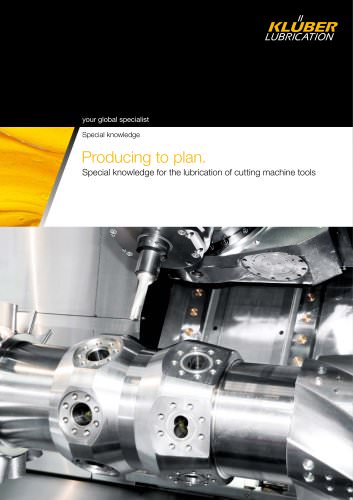

Klber speciality lubricants - always a good choice 3 Greases for the lubrication of spindle bearings 4 Oils for the lubrication of spindle bearings 6 Paste for the lubrication of clamping devices 8 Greases for the lubrication of gears in drilling and milling heads 10 Anticorrosion fluid for gears in drilling and milling heads 12 Greases for the lubrication of drive and guide systems 14 B064001002 / Edition 08.08, replaces 11.07-2 © ©ictore S.2: FORKARDT DEUTSCHLAND GmbH 2

Open the catalog to page 2

Klber spcial lubricants - always a good choice Quality put to the test 驕 Klber has more than 110 test rigs, which include standardised equipment as well as tools Klber has developed to regularly test the quality of its products. 鹕 Test results prove the high quality level and provide you with a solid basis for selecting the right lubricant. You can obtain Klչber products of consistent quality made at our production plants worldwide. All-around service Comprehensive consulting and technical support Օ Development of plant lubrication charts Automatic lube point monitoring by means of...

Open the catalog to page 3

Greases for the lubrication of spindle bearings Application/ requirement Speed factor 1) n x d m [min'1mm], approx. Base oil Thickener Corrosion protection (EMCOR test) DIN 51802 Apparent dynamic viscosity, Klber viscosity grade 2) Worked penetration DIN ISO 2137 [0.1 mm] Base oil viscosity DIN 51562 [mm2/s] at 40°C, approx. Bearings in indirectly driven spindles Spindle bearings with medium speeds 600 000 Synthetic hydrocarbon oil Barium complex soap 3) s 1 M/S 265 to 295 100 Spindle bearings with high speeds 1 000 000 Ester oil / synthetic hydrocarbon oil / mineral oil Barium complex soap...

Open the catalog to page 4

Base oil viscosity DIN 51562 [mm2/s] at 100°C, appro x. Product Artic le number Benefits 14.5 ISOFLEX TOPAS NB 152 004145 Long component life due to high load-carrying capacity and corrosion protection Օ Long-term or for-life lubrication due to good resistance to water, cooling lubricants and aging 4.5 ISOFLEX NBU 15 004026 Longer component life due to high load-carrying capacity and corrosion protectio n. Օ For long-term or fot-life lubrication due to good resistance to water and cooling lubricants as well as good resistance to aging Tried and tested for many yearn, cspecially in...

Open the catalog to page 5

Oils for the lubrication of spindle bearings Application / Speed factor 11 Base oil Copper Viscosity Viscosity Demulsifying requirement n x d [min'<mm] corrosion DIN 51562 DIN 51562 ability DIN EN ISO [mm2/s] [mm2/s] DIN 51599 2160, at 40°C, at 100°C, (ASTM D-1401) 24h/100°C approx. approx. 54°C, 30 min. [ml] Spindle bearings Synthetic no data available hydrocarbon oil 1 - 100 32 6.0 no data available no data available 1 - 100 46 8.0 no data available > 2 500 000 1 - 100 68 10.5 no data available Spindle bearings Synthetic no data available hydrocarbon oil 1 - 100 15 3.5 40/37/3 no data...

Open the catalog to page 6

Product Article number Benefits CONSTANT OY32 K OY46 K OY68 K 028101 028102 028103 High corrosion protection capacity for long component life Օ Good load-carrying capacity ensures smooth running Uong component life due to lower steady-state temperature of bearing Օ Low lubriuant costs due to good resistance to oxidation and aging Low change in viscosity with alternating tempթratures increases efficiency Klber Summ it HySyn FG 15 HySyn FG 32 HySyn FG 46 HySyn FG 68 050039 050013 050014 050015 Lower risk potential for machine operators rusulting out of incidental, technically unavoidable...

Open the catalog to page 7

Paste for the lubrication of clamping devices Application / requirement Clamping force loss1) [%] Base oil Thickener Solid lubri-cant Four-ball wear test, welding load DIN 51350 pt. 04 [N] Corrosion protection (EMCOR test) DIN 51802 Apparent dynamic viscosity, Klber viscosity grade 2) Lubrication of clamping devices < 15 Mineral oil Barium complex soap 3) inorganic > 4 000 s 1 M/S Worked penetration DIN ISO 2137 [0.1 mm] 250 to 270 1) Clamping force block KSP 160, 6 bar, max. path feed rate 0.52 m/min. Quasi-stationary operation achieved at: -initial lubrication after approx. 500 clamping...

Open the catalog to page 8

Base oil viscosity DIN 51562 [mm!/s] at 40°C, appro x. Base oil viscosity DIN 51562 [mm2/s] at 10)O°C, appro x. Product Artic le number Benefits 46 7 ALTEMP Q MB 50 005011 Low lubricant costs for initial and relubrication due to long service life of water- and media-resistant produ ct Օ Good wear and corrosion protestion help to reduce assembly forces and screw torques and prevent tribo- and fretting corrosion High prcssu re aSsorption capacity enables constant clamping forces an d consequently ensures properly fixed tools or workpiece in machine tool chucks 9

Open the catalog to page 9

Greases for the lubrication of gears in drilling and milling heads Application / requirement Load-dependent max. circum-ferential speed in intermittent operation [m/s] Base oil Thickener Corrosion protection (EMCOR test) DIN 51802 Apparent dynamic viscosity, Kliiber viscosity grade 1) Worked penetraͭtion DIN ISO 2137 [0.1 mm] Base oil viscosity DIN 51562 [mm2/s] at 40°C, approx. Base oil viscosity DIN 51562 [mm2/s] at 100°C, approx. Grease lubrication of gears in drilling and milling heads < 4 Synthetic hydrocarbon oil / mineral oil Special calcium soap / polyurea s 1 EL/L 355 to 385 130 16...

Open the catalog to page 10

Product Article number Benefits Notes Klbersynth G 34-130 020501 High protection against corrosion - especially tribocorrosion - long component life 镕 Good rsistance to water and aging, long-term lubrication Low consistency allows application by means of automatic metering Systems Particularly for "fluid lubrication" Kl镹bersynth GE 46-1200 027035 Longer component life due to good load-carrying capacity and wear protection (FZG > 12) Օ Low consistency allows application by means of automatic metering Systems Particularly for "fluid lubrication" or for spiran bevel (palloid) gears ISOFLEX...

Open the catalog to page 11

Anticorrosion fluid for gears in drilling and milling heads Application / requirement Corrosion protection properties of oils DIN ISO 7120, steel 24h/60°C Base oil Thickener Conservation and / or corrosion no rust Synthetic hydrocarbon oil / Lithium soap protection of gears in milling heads as mineral oil well as other metal surfaces 12

Open the catalog to page 12All Klüber Lubrication catalogs and technical brochures

-

KlueberEfficiencySupport

7 Pages

-

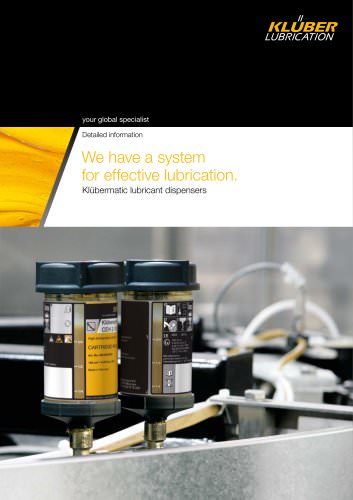

Klübermatic lubricant dispensers

13 Pages

-

Driving with Klüber Lubrication.

15 Pages

-

Geared up for success.

32 Pages

-

All sprays at a glance

2 Pages

-

Bonded coatings

16 Pages

-

Automotive industry

16 Pages

-

Cement industry

2 Pages

-

Tribojournal edition 1 - 2011

32 Pages

-

Seaworthy

24 Pages

-

Pneumatics

24 Pages