Catalog excerpts

your global specialist Industrial sector cement production. Speciality lubricants meeting the highest requirements

Open the catalog to page 1

Speciality lubricants for the cement industry: Speciality lubricants for the cement industry Increased efficiency, productivity and reliability and reliability Increased efficiency, productivity Speciality lubricants for the cement industry Optimally equipped with our speciality lubricants Lubricants for raw cement plant transport Lubricants for crushing processes Lubricants used in clinker production Lubricants for open gear drives Further applications in the cement industry Onsite services offered by Klüber Lubrication The right lubricant at the right place at the right time Producing...

Open the catalog to page 2

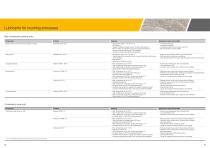

Cement plant applications: Optimally equipped with our speciality lubricants Quarry Raw material silo Raw mill Pre-heater tower Pre-blending dome Additions Finishing mill 4

Open the catalog to page 3

Lubricants for raw cement plant transport Apron feeders, belt & screw conveyers, bucket elevators, stackers & reclaimers Better protection against temperature influence and shock loads During the transport of raw material and additional materials, bearings and joints are mainly influenced by excessive contamination from dust and water in combination with high temperature fluctuations. The consequence: high wear and short lifetime of the loaded components. High-quality speciality lubricants help you prevent damage; the right lubricant protects your machines against temperatures and shock...

Open the catalog to page 4

Lubricants for crushing processes Crushing processes are particularly demanding for bearings, as vibrations, shocks and contamination are extremely high, and temperatures fluctuate considerably. Speciality lubricants can protect highly loaded bearings in these processes; they reduce wear, extend maintenance intervals and increase reliability. We make speciality lubricants to suit these requirements: they have the right viscosity and consistency combined with the right additives and offer reliable lubricant pumpability. They are also chemically and physically stable, contributing to long...

Open the catalog to page 5

Lubricants for crushing processes Vertical roller mills Oil lubrication Component Application notes and benefits Main bearing / roller bearing –– Max. temperature up to 160 °C (Klübersynth GH 6) –– Max. temperature up to 150 °C (SYNTHESO HT) –– Polyglycol synthetic oil –– Excellent results in FAG FE8 rolling bearing test –– Excellent wear protection, ageing and oxidation resistance, good viscosity-temperature behaviour and very good thermal stability –– Prevents premature rolling bearing failure –– Reduces power losses and improves energy efficiency –– Extended service life –– Approved by...

Open the catalog to page 6

Lubricants for crushing processes Separators Component Application notes and benefits –– Temperature range -40 °C to 150 °C –– Grease based on mixture of synthetic hydrocarbon oil, mineral oil and a special lithium soap –– NLGI grade 2 –– Speed factor up to 1,000,000 mm/min –– Longer service life –– Less maintenance –– Prolongs bearing life subjected to vibration and shock loads –– Temperature range -20 °C to 140 °C –– NLGI grade 2 –– Extreme-pressure grease based on highly viscous mineral oil, special lithium soap, antiwear, anti-oxidant and anticorrosion additives –– Protects highly...

Open the catalog to page 7

Lubricants for crushing processes Roller presses In bearings subjected to high shock loads the lubricating film has to ensure trouble-free operation, especially as lubrication starvation, contamination or the wrong lubricant can quickly contribute to bearing failure. Factors like long lead times for delivery of expensive spares can have an adverse effect on production and cost. Typical roller press bearings are cylindrical roller bearings operating at maximum 75 °C. We need to ensure adequate lubricant film formation to prevent metal-to-metal contact between the rollers and bearing...

Open the catalog to page 8

Lubricants for crushing processes Tube mills / ball mills Component Application notes and benefits Pinion bearings –– Temperature range -10 °C to 150 °C –– NLGI grade 1 –– Grease consisting of highly viscous mineral hydrocarbon oil (ISO VG 1500), special lithium soap and particularly effective extreme pressure / antiwear (EP / AW) additives –– Contains solid lubricants (MoS2 and graphite) –– Increased bearing life –– Improved pumpability –– Increased productivity due to less downtime –– Recommended by leading OEMs Neck bearings / drive gearboxes –– Max. temperature up to 100 °C ––...

Open the catalog to page 9

Lubricants for crushing processes Bed compression grinding units Component Application notes and benefits Roller bearings / plummer blocks / reducer coupling –– Temperature range -10 °C to 150 °C –– NLGI grade 1 –– Grease consisting of highly viscous mineral hydrocarbon oil (ISO VG 1500), special lithium soap and particularly effective extreme pressure / antiwear (EP / AW) additives –– Contains solid lubricants (MoS2 and graphite) –– Increased bearing life –– Improved pumpability –– Increased productivity due to less downtime –– Recommended by leading OEMs Rotary joints –– Temperature range...

Open the catalog to page 10

Lubricants used in clinker production Pre-heating The pre-heating section is marked by extreme conditions like high temperature, speed, contaminants and others. The lubrication of bearings subjected to thermal loads is a demanding task. Speciality lubricants from Klüber Lubrication are designed to increase the component life in challenging situations. Application notes and benefits Gearbox drive manifold –– Max. temperature up to 160 °C –– Polyglycol synthetic oil –– FZG scuffing test, A / 8.3 / 90, scuffing load stage ≥ 14 –– Excellent results in FAG FE8 rolling bearing test –– Excellent...

Open the catalog to page 11All Klüber Lubrication catalogs and technical brochures

-

KlueberEfficiencySupport

7 Pages

-

Klübermatic lubricant dispensers

13 Pages

-

Driving with Klüber Lubrication.

15 Pages

-

Geared up for success.

32 Pages

-

All sprays at a glance

2 Pages

-

Bonded coatings

16 Pages

-

Automotive industry

16 Pages

-

Cement industry

2 Pages

-

Tribojournal edition 1 - 2011

32 Pages

-

Seaworthy

24 Pages

-

Pneumatics

24 Pages