Catalog excerpts

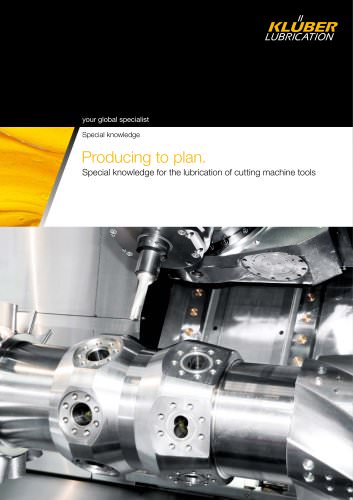

your global specialist Special knowledge Economical lubrication for every component. Speciality lubricants for machine tools

Open the catalog to page 1

Think economics from the start Kluber Lubrication has the right solution for manufacturers and operators of machine tools. Think economics from the start 3 The lubrication of spindle bearings 4 The lubrication of work holding systems 6 The lubrication of drilling and milling head gear units 7 The lubrication of drive and guide systems 8 Greases for the lubrication of spindle 10 Oils for the lubrication of spindle bearings 12 Pastes for the lubrication of clamping devices 14 Greases for the lubrication of gears in drilling and milling heads 16 Corrosion...

Open the catalog to page 2

The lubrication of spindle bearings Machine tool main spindles running at higher speeds enable ever greater machining rates and shorter machining times per workpiece. These high speeds result in demanding operating conditions for rolling bearings. Spindle bearings are required to operate at high speed factors (n × dm) and run with reduced friction to keep bearing temperature low. The bearings have to carry both radial and axial loads. Naturally, premature bearing failure must be prevented. How to select the right lubricating grease If you wish to determine the free bearing space with full...

Open the catalog to page 3

The lubrication of work holding systems It is important to make sure that the correct lubricant is chosen for lubrication of the work holding chuck. After all, the principal task is to generate a constant defined clamping force for a high number of clamping cycles. If the clamping force decreases, tools or workpieces may come loose. This applies to all types of chuck designs – scroll, cam or spiral chucks. Lubricating pastes have proven very useful in these applications as they adhere well to the friction points and provide sufficient lubricity even when applied as a very thin film. Most...

Open the catalog to page 4

The lubrication of drive and guide systems Speed-viscosity ratio In most modern machine tools, workpieces and tools are positioned by means of antifriction guideways or slideways. They are normally moved by ball screws. 15 m/min to 60 m/min vibration < 1 m/s2 The correct advanced speciality lubricants support your components in meeting these requirements. Speciality lubricants made by Klüber Lubrication protect against wear also when subject to micro-movements, and due to reduced friction they facilitate machine start-up. They provide high-performance corrosion protection, a good...

Open the catalog to page 5

Corrosion protection (EMCOR test) DIN 51802 Worked penetration DIN ISO 2137 [0.1 mm] Base oil viscosity DIN 51562 [mm2/s] at 40 °C (104 °F), approx. Base oil viscosity DIN 51562 [mm2/s] at 100 °C (212 °F), approx. Benefits and notes ISOFLEX TOPAS NB 152 Synthetic Barium hydrocarbon oil complex soap 2) Bearings in indirectly driven spindles Spindle bearings 600,000 with medium speeds Spindle bearings 1,600,000 ISOFLEX NBU 15 Ester oil / Barium < 1 with high speeds synthetic complex soap 2) Spindle bearings 2,000,000 Kluberspeed BF 72-22 Ester oil...

Open the catalog to page 6

Application Product Spindle bearing oil CONSTANT OY 32 K OY 46 K OY 68 K - Good load-carrying capacity ensures smooth running - Long component life due to good corrosion protection - Long component life due to low steady-state temperature of bearing - Low lubricant costs due to good resistance to oxidation and ageing Spindle bearing oilt Kluber Summit HySyn FG 15 HySyn FG 32 HySyn FG 46 HySyn FG 68 - Low change in viscosity with alternating temperatures increases efficiency - Good environmental compatibility due to low evaporation rate - High process stability, e.g. due to good foaming...

Open the catalog to page 7

Application Product Clamping Base oil Thickener Solid lubricant Four-ball wear test, Corrosion force loss 1) welding load protection [%] DIN 51350 pt. 04 [N] (EMCOR test) Base oil viscosity DIN 51562 [mm2/s] at 40 °C (104 °F), approx. Base oil viscosity DIN 51562 [mm2/s] at 100 °C (212 °F), approx. Benefits and notes Lubrication of ALTEMP Q NB 50 < 15 Mineral oil Barium Inorganic > 4,000 < 1 work holding complex soap2 systems in machine tools Lubrication of Kluberpaste ME 31-52 < 10 Mineral oil Calcium Inorganic > 4,000 < 1 work holding...

Open the catalog to page 8

Application Load-dependent Product Base oil max. circumferential speed in intermittent operation [m/s] Thickener Corrosion protection (EMCOR test) DIN 51802 Worked penetration DIN ISO 2137 [0.1 mm] Base oil viscosity DIN 51562 [mm2/s] at 40 °C (104 °F), approx. Base oil viscosity DIN 51562 [mm2/s] at 100 °C (212 °F), approx Benefits and notes Grease lubrication of < 4 Klubersynth G 34-130 Ester oil / gears in drilling and synthetic milling heads hydrocarbon Special calcium < 1 soap / polyurea 130 16 - Good protection against corrosion for long component life -...

Open the catalog to page 9

Anticorrosion fluid for gears in drilling and milling headsApplication Product Corrosion protection Base oil Thickener Benefits and notes properties of oils DIN ISO 7120, steel 24 h / 60 °C (140 °F) - Longer component life due to good resistance to water and corrosion protection - Compatible with many lubricating greases - Increases the corrosion protection properties of lubricating greases Corrosion Klubersynth BZ 44-4000 No rust Synthetic hydrocarbon oil / mineral oil Lithium soap protection of gears in milling and drilling heads as well as other metal surfaces Fog...

Open the catalog to page 10

Base oil viscosity DIN 51562 [mm2/s] at 40 °C (104 °F), approx. Base oil viscosity DIN 51562 [mm2/s] at 100 °C (212 °F), approx. Benefits and notes Initial lubrication < 15 MICROLUBE GL 262 Mineral oil Special 265 to 295 lithium soap hydrocarbon oil / calcium soap mineral oil 280 20 - Especially for high loads and vibrations - Long relubrication intervals due to good wear protection - Higher consistency for vertical mounting positions. - For relubrication MICROLUBE GL 261 with a softer consistency - Relubrication via grease nipple / grease gun 130 16 - Longer...

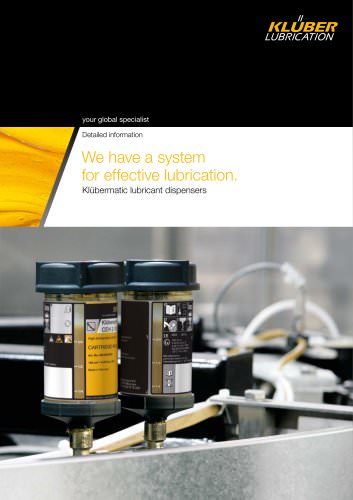

Open the catalog to page 11All Klüber Lubrication catalogs and technical brochures

-

KlueberEfficiencySupport

7 Pages

-

Klübermatic lubricant dispensers

13 Pages

-

Driving with Klüber Lubrication.

15 Pages

-

Geared up for success.

32 Pages

-

All sprays at a glance

2 Pages

-

Bonded coatings

16 Pages

-

Automotive industry

16 Pages

-

Cement industry

2 Pages

-

Tribojournal edition 1 - 2011

32 Pages

-

Seaworthy

24 Pages

-

Pneumatics

24 Pages