Catalog excerpts

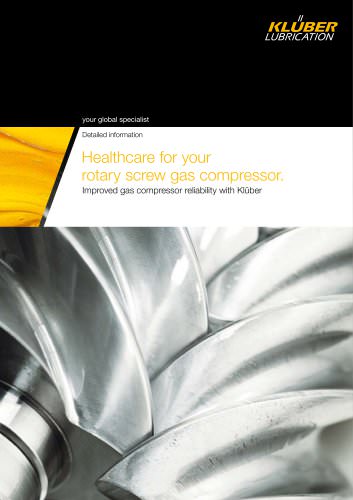

your global specialist Detailed information Healthcare for your rotary screw gas compressor. Improved gas compressor reliability with Klüber

Open the catalog to page 1

No matter where your gas compressor operates, we are specialists for its effective lubrication Rotary screw gas compressors 1.1 Many compressor shut-downs due to wear? Viscosity and gas solubility are a decisive factor 5 1.2 Problems with residues, deposits and sludge in the oil? Chemical compatibility may be the cause 8 1.3 High oil consumption and high oil carryover to the gas stream? Low evaporation and carryover 1.4 The art of choosing the right gas compressor oil - 1.5 Specialty oils versus mineral oils-an example 14 1.6 A specialist for every application - Kluber oils for rotary screw...

Open the catalog to page 2

No matter where your gas compressor operates, we are specialists for its effective lubrication. Whether for on- or off-shore applications, whether for the extraction of oil or gas, for refineries, the chemical or petrochemical industry – Klüber offers special lubricants that are precisely tuned to your needs and the types of gases in your compressor. We regard the lubricant as an essential design element of the compressor, just as bearings, rotors or slide valves. More than 80 years of practical experience in research, development and application of special lubricants ensure a product...

Open the catalog to page 3

Klüber Lubrication help you avoid such lubrication-related problems. A detailed analysis of the gas stream in the compressor and an extraordinarily wide range of fully and semi-synthetic compressor oils enable us to offer you a solution that optimally suits the needs of your individual compression process – anywhere in the world. After all, the choice of lubricant has a decisive effect on the reliability of your rotating equipment, your production and hence also your competitiveness. Klüber Summit gas compressor lubricants: less downtime due to maintenance lower spare parts cost higher...

Open the catalog to page 4

Rotary screw gas compressors 1.1. Many compressor shut-downs due to wear? Viscosity and gas solubility are a decisive factor With the right lubricating oil you will not only reduce wear and increase the life of individual components as well as that of your machines as a whole, but you will also boost your operational reliability and hence your profits. But which lubricating oil will release this potential? Lubricating oils in rotary screw-type compressors for process gases fulfill a number of different tasks: which should under all operating conditions comply with the instructions provided...

Open the catalog to page 5

Klüber calculates viscosity Every gas stream is unique. Klüber Lubrication is the only lubricant supplier to have tailor-developed a program to calculate the tendency of the individual gases to be dissolved in lubricating oil. All factors determining this tendency are taken into account, including the actual operating conditions: 1. Pressure: The higher the compression, the higher the tendency of the gas to be dissolved in the oil. 2. Temperature: The higher the compression temperature, the lower the tendency of the gas to be dissolved in the oil. 3. Molecular weight: The higher the...

Open the catalog to page 6

A calculation that pays A lubricant with a viscosity that is in line with manufacturer's instructions inevery stage of compressor operation helps you to extend your production capacity. After all, less compressor wear leads not only to a higher degree of compressor availability and a better utilization longer component life and less production loss due to maintenance downtime, higher operational and production reliability throughout your plant An example: The first step is analyzing the gas stream composition: 54 % methane CH4 16 % C2H10, C5H12, C6H14 16 % hydrogen H2 36 ppm hydrogen...

Open the catalog to page 7

1.2. Problems with residues, deposits and sludge in the Oil. Chemical compatibility may be the cause Reduce your maintenance and operating costs by using compressor oils from Klüber Lubrication. How’s that possible? Because with Klüber oils you will need less new oil filters and separators, reduce reaction by-products in the compressor and cut your oil consumption. The pitfalls of chemistry: reaction products. When mixing under high pressure and temperature, gases may not only be dissolved in the oil, they may also react with base oils or additives. Conventional mineral oils, in particular,...

Open the catalog to page 8

Our reaction: low-reaction lubricants. To avoid the formation of reaction by-products and prevent avoidable costsfor maintenance and spare parts, Klüber Lubrication checks the compatibility of gas stream and lubricating oil before it is used in a particular compressor. less reaction by-products, deposits and sludge lower filter consumption due to less deposits lower costs due to longer oil separator life lower oil consumption due to longer oil change intervals and high separator performance less wear on rotors and bearings caused by reaction by-products (consequent longer rotor and bearing...

Open the catalog to page 9

1.3. High oil consumption and high oil carryover to the gas stream? Low evaporation and carryover for a pure gas stream Our special lubricants for the compression of inert gases such as pure hydrogen or nitrogen ensure that the gas stream remains pure. After all it's the compressor that needs lubrication, and not the gas stream. When standard oils beat it. At high compression temperatures, the oil injected into the compressor tends to evaporate – in particular standardquality mineral oils – and is carried along with the gas stream. There it is present in two forms: as oil vapor and as oil...

Open the catalog to page 10

Klüber Summit: synthetic problem solvers. This means for the compression process: With our Klüber Summit oils we offer you an extremely wide choice of fully and semi-synthetic products for all types of compression processes. The high resistance to evaporation of these oils comes into play in particular at temperatures above 70°C, which ensures that the amount of oil vapor carried along in the gas stream is kept to a minimum. Highly reliable processes, especially chemical ones Less oil carryover, continuously high efficiency and long service life of catalysts and downstream components This...

Open the catalog to page 11All Klüber Lubrication catalogs and technical brochures

-

KlueberEfficiencySupport

7 Pages

-

Klübermatic lubricant dispensers

13 Pages

-

Driving with Klüber Lubrication.

15 Pages

-

Geared up for success.

32 Pages

-

All sprays at a glance

2 Pages

-

Bonded coatings

16 Pages

-

Automotive industry

16 Pages

-

Cement industry

2 Pages

-

Tribojournal edition 1 - 2011

32 Pages

-

Seaworthy

24 Pages

-

Pneumatics

24 Pages