Catalog excerpts

your global specialist Detailed information Keeping machines well lubricated Speciality lubricants for the beverage industry

Open the catalog to page 1

NSF H1 lubricants across the line 3 Conveyor systems 4 Enclosed gears (spur-, bevel- and worm gears) 4 Filling, capping and labelling machines 6 Seals6 Shrink wrap tunnels 8 Screw threads 8 Compressors8 On the intention of this lubricant selection brochure 2 B114003002 / Edition 02.11, replaces edition 12.09 10

Open the catalog to page 2

NSF H1 lubricants across the line There are three aspects which are of particular importance for beverage production: consumer protection, reliable manufacturing processes and energy efficiency. Klüber’s synthetic high-performance lubricants with NSF H1 registration help you obtain these objectives, as they are capable of a lot more than friction reduction, lowering operating temperatures and increasing components’ service life. Depending on the application conditions, lubricants meeting a wide range of requirements from hygienic filling in aseptic areas to high resistance to water washdown...

Open the catalog to page 3

Application Application points / machine components Klüber speciality lubricant NLGI grade Base oil Thickener Conveyor systems Palletisers, drives and conveyor chains Klüberoil 4 UH1 1500 N Spray Not applicable Synthetic hydrocarbon oil / ester1) None Dry lifetime lubrication of chains Klüberplus SK 02-295/ Klüberoil 4 UH1 1500 N Dispersion Not applicable Wax None Conveyor bearings Klübersynth UH1 14-222 2 Synthetic hydrocarbon oil Aluminium complex soap Steel / plastic slatted conveyors Klübertop TP 38-901 Not applicable Not applicable PTFE High-performance gear oils Klüberoil 4 UH1 100...

Open the catalog to page 4

Upper service temperature approx. Lower service temperature approx. Application notes and benefits 1201) [°C] 248 [°F] –20 [°C] – 4 [°F] –– Drive and conveyor chain lubrication where maximum adhesion is required in for example high speed applications –– Good wear protection to optimise chain life –– Low foaming of spray to ensure maximum penetration to main friction points of the chain 60 [°C] 140 [°F] –30 [°C] –22 [°F] –– Typically 60 % of Klüberplus SK 02-295 dispersed by 40 weight % of Klüberoil 4 UH 1 1500 N –– Applied by hot bath dip to provide lubrication for life of slow to medium...

Open the catalog to page 5

Application Application points / machine components Klüber speciality lubricant NLGI grade Base oil Thickener Filling, capping and labelling machines Lifting rods and guides in filling machines PARALIQ P40 Spray Not applicable Paraffinic mineral oil1) None Klüberfood NH1 6-10 Not applicable Polygylcol None Open drive gears in filling machines Klüberfood NH1 14-222 Spray 2 Synthetic hydrocarbon oil1) Aluminium complex soap1) Can seamers Klüberfood NH1 14-261 1 Paraffinic mineral oil Aluminium complex soap1) Centralised grease systems in filling machines Klübersynth UH1 14-151 1 Synthetic...

Open the catalog to page 6

Upper service temperature approx. Lower service temperature approx. Application notes and benefits 601) [°C] 140 [°F] –10 [°C] 14 [°F] –– Light oil to reduce friction and optimise sliding actions, e.g. in capping heads 60 [°C] 140 [°F] 0 [°C] 32 [°F] –– Good wear and corrosion protection –– Particulary suitable for friction points subject to sugar, such as rocking levers, chain links, sensors, to reduce sugar adhesion –– ISO 21469 certified 1201) [°C] 248 [°F] –25 [°C] –13 [°F] –– Sprayable grease for ease of application on open gears & slideways –– Good wear and corrosion protection. ––...

Open the catalog to page 7

Application Application points / machine components Klüber speciality lubricant Base oil Thickener Upper service temperature approx. Lower service temperature approx. Shrink wrap tunnels Transport and drive chains Klüberfood NH1 CH2-220 Ester None 250 [°C] 482 [°F] 0 [°C] 32 [°F] Screw threads Screw threads Klüberoil 4 UH1-15 Spray Synthetic hydrocarbon oil / ester oil1) None 1101) [°C] 230 [°F] –45 [°C] –49 [°F] Screw threads and slides Klüberpaste UH1 84-201 Synthetic hydrocarbon oil Solid lubricant / PTFE 120 [°C] 248 [°F] –45 [°C] –49 [°F] Air screw compressors, pneumatics and...

Open the catalog to page 8

Application notes and benefits –– Low oil evaporation rate resulting in low residue formation and reduced oil consumption –– ISO 21469 certified –– Light penetrating oil to aid disassembly and reduce downtime –– Universal white assembly and thread paste –– Excellent low-temperature behaviour; good load-carrying capacity, good corrosion protection –– Neutral towards alloyed steels –– Also suitable for low-speed plain bearings, for guide rails, hinges, rollers etc. –– Synthetic base oil with low volatility ensuring minimum carry-over, minimising contamination risks and consumption, providing...

Open the catalog to page 9

On the intention of this lubricant selection brochure The intention of this lubricant selection is to provide a logical guide through the Klüber Lubrication specialised product range. The structure of the brochure considers firstly the various application requirements and then leads you toward selection of the appropriate lubricant solution. Whenever products appear to have similar properties, we highlight the differences in grey in the respective fields to assist with the final product selection. Should you not find a lubricant “tailored” exactly to your requirements we recommend contact...

Open the catalog to page 10

Publisher and Copyright: Klüber Lubrication München KG Reprints, total or in part, are permitted only prior consultation with Klüber Lubrication München KG and if source is indicated and voucher copy is forwarded. The data in this document is based on our general experience and knowledge at the time of publication and is intended to give information of possible applications to a reader with technical experience. It constitutes neither an assurance of product properties nor does it release the user from the obligation of performing preliminary field tests with the product selected for a...

Open the catalog to page 11All Klüber Lubrication catalogs and technical brochures

-

KlueberEfficiencySupport

7 Pages

-

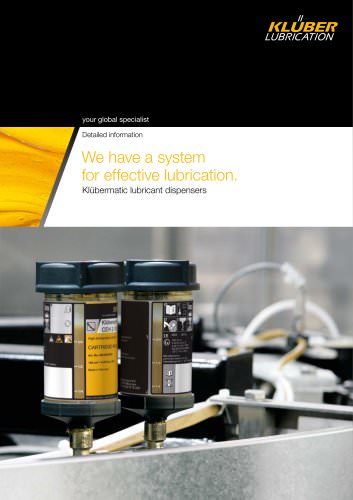

Klübermatic lubricant dispensers

13 Pages

-

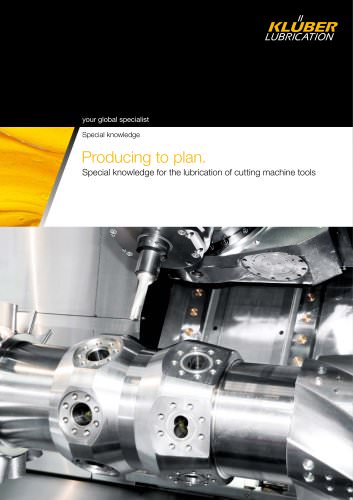

Driving with Klüber Lubrication.

15 Pages

-

Geared up for success.

32 Pages

-

All sprays at a glance

2 Pages

-

Bonded coatings

16 Pages

-

Automotive industry

16 Pages

-

Cement industry

2 Pages

-

Tribojournal edition 1 - 2011

32 Pages

-

Seaworthy

24 Pages

-

Pneumatics

24 Pages