Catalog excerpts

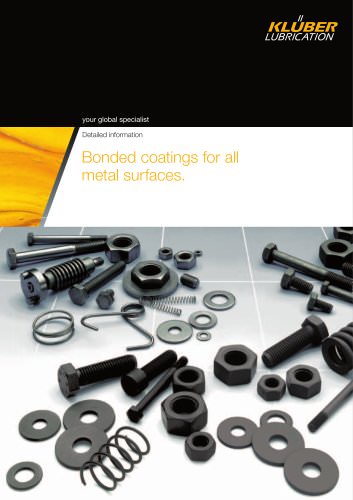

Contents Page General information on bonded coatings 3 Composition 3 Performance 3 Function 4 Design dtails 5 Pretreatment and application 6 Application of bonded coatings 7 From the requirements profile to series application 8 Slection examples 9 Coating of metal/metal components 9 Special applications 10 Assembly of components 11 Product survey 12 Technical questionnaire 13

Open the catalog to page 2

General information on bonded coatings Composition Performance The composition of a bonded coating is similar to that of an i ndustrial lacquer, however instead of pigments it contains lubricating substances. The main constituents of a bonded coating are: - Solid lubricant e. g. polytetrafluoroethylene (PTFE), molybdenum disulfide (MoS2), graphite or a combination of solid lubricants - Binder (organic or inorganic, made up of one or two components) - Solvent (organic or water) Further constituents are for example coloring agents or corrosion inhibitors etc. Once applied and hardened, bonded...

Open the catalog to page 3

ttVVWW Function Once hardened, the bonded coating forms a thin, dry and firmly adhering lubricant layer, which spartes the friction components in contact, thus reducing friction and wear considerably. The service life of a bonded coating layer is limited and d颩pends on diffrent product characteristics, the most important being the binder's wear resistance and elasticity, and the adhesiveness to the component surface. Frictional stresses gradually wear off the bonded coating layer, which is why this type of lubrication is also referred to as "transfer lubrication" or "wear-related...

Open the catalog to page 4

Design dtails The components to be coated should be designed following certain criteria: No sharp edges This applies both to the friction body to be coated and the opposing body. Sharp-edged opposing bodies scratch the coating. Coated parts with sharp edges tend to corrode around the edges and have a shorter life because the coating is thinner in these areas. Tolrances The acceptable tolerances have to be determined in accordance with the layer thickness. Standard layers are between 7 and 15 um. Component According to our experience, only one friction body is usually coated for cost...

Open the catalog to page 5

ttVVWW Pretreatment and application The surfaces to be coated always have to be free of oil, grease, water, corrosion, scale etc. Prior to applying a bonded coating, the component surfaces (substrate) have to be thoroughly degreased. The cleanliness of the surface to be coated is the most important pre-requisite for good adhsion and hence also for the function of the bonded coating. Furthermore, sufficient surface rough-ness is required for the bonded coating to become firmly rooted on the component surface. Degreasing and cleaning can be done in an ultrasonics bath using alcaline, aqueous...

Open the catalog to page 6

Application of bonded coatings Component with clean surface, R = 1-2 um T Degreasing (e. g. ultrasonic bath) r i _L Mechanical roughening Chemical roughening (phosphatizing) (sand blasting) 1 Cleaning Rinsing

Open the catalog to page 7

From the requirements profile to sries application Initial idea _L ~| Customer's -I responsibility -i If required, | assistance by Klber specialists Define requirements (technical questionnaire) Kl鹹ber's responsibility Select bonded coating (brochure) Coating contractor _L Parts to be coated in customer's plant? YES NO Dtermine coating process taking into account local possibilities Detei coating mine process If necessary, coat preliminary samples at Klber Lubrication Sample coating at your company Sample coating carried out by coating contractor* T Application test Series approval T Series...

Open the catalog to page 8

Slection examples Coating of component/machine l驩ment Axles Bolts Sealing rings Sliding guides - sliding dises - sliding tubes Guiding axles Guiding bolts Guiding tubes Springs - spiral springs - flat spiral springs - dise springs Chain pins Clamps Armatures Camshafts Pistons Hinges - furniture hinges/pins - hinge bolts - eylinder bolts Loek parts Seat belt parts Pins Valves - valve armatures Hub-shaft connections Shafts Single-part application (injection) Standard value Surface pressure Service temperature, °C11 Kluber Product Water base Org. binder Thermo-setting air drying/ hardening p <...

Open the catalog to page 9

i\.r. 'J. Spcial applications Component/Application Kluber bonded coating Advantage Threaded spindles -40 to 230 °C FLUOROPAN 340 NP A/B Lifetime lubrication Plain bearings -40 to 120 °C Klubertop TG 05 N Improves runnning-in, wear protection Belt tensioners -40 to 120 °C Klubertop TP 02-131 Wear protection, lower friction coefficient Chain pins UNIMOLY C 220 Improves running-in -10to260 °C Pistons for Klubertop TP 39 N A/B Wear protection, air conditioning compressors noise rduction Piston skirt Klubertop TG 05 N Wear protection -40 to 200 °C Armatures FLUOROPAN 340 NP A/B Lifetime...

Open the catalog to page 10

Assembly of components Service Kluber bonded temprature, coating °C1) Water base Bin-der Thermo-| setting air drying/ hardening Press-in and press-on assembly Bolts Pins Rivets Bushings Sleeves Rolling bearings Wheels Flanges -180 to 450 UNIMOLY C 220 Power-locking and positive connections Screw-bolt connections Wedge-type connections Feather key connections Woodruff key connections -180 to 450 UNIMOLY C 220 (Kluberplus SK 12-205) Splined shaft connections Involute spline connections Serrated hub connections Screw connections Screws Threaded bolts Threaded rods Threaded nuts -180 to 450...

Open the catalog to page 11

Product survey ■r & <§>' $ 4 ^ 4 / / / * # / J* J* <50 * # & & ^ Service temprature range °C1) -40 to +230 -40 to +180 -40 to +180 -40 to +80* -40 to +230 -40 to +300 -40 to +220 -180 to +450 Standard values of max. surface pressure [N/mm2] p>10 p<10 p<10 p<10 p>10 p>10 p>10 p>10 PTFE Solid lubricant MoS2 Graphite Air hardening2) Thermosetting2) 镕 organic Binder base inorganic Water-miscible Corrosion protection2) Resistance to chemicals2) Single-part application Bulk application, centrifuging Bulk application Tumbling *) The stress at high tempratures dpends on the type and frequency of...

Open the catalog to page 12All Klüber Lubrication catalogs and technical brochures

-

KlueberEfficiencySupport

7 Pages

-

Klübermatic lubricant dispensers

13 Pages

-

Driving with Klüber Lubrication.

15 Pages

-

Geared up for success.

32 Pages

-

All sprays at a glance

2 Pages

-

Bonded coatings

16 Pages

-

Automotive industry

16 Pages

-

Cement industry

2 Pages

-

Tribojournal edition 1 - 2011

32 Pages

-

Seaworthy

24 Pages

-

Pneumatics

24 Pages