Catalog excerpts

TubesComponents Valves Units Engineering >

Open the catalog to page 1

k-flex sealing material. K-flex > TubesComponents Valves Units Engineering does not only ensures a long service life, high resi- stance to aggressive media and temperatures but is also very easy to clean. The GEMBRA-aseptic valve series stands out dueto its uncompromising hygienic design. It is based on process-safe and stable aseptic diaphragm sealing. The use of an established technology ensures a safe process and an efficient operation. GEMBRA valves are available as single-seat, change-over valves and leakage-proof double- seat valves. GEMBRA aseptic technology has been certified by the...

Open the catalog to page 2

Advantages of GEMBRA Technology: contamination free aseptic function due to diaphragm hygienic design with excellent cleanability durable k-flex sealing material big opening stroke Product-conserving media flow Fast and simple assembly with easily accessible parts > Optimised flow in the GEMBRA valve cost-efficient maintenance Sinus-diaphragm seals made of the established k-flex sealing material stand out thanks to theirhigh level of flexibility even when there are rapid temperature changes. The high strength of the diaphragm throughout the whole temperature range and the low flow...

Open the catalog to page 3

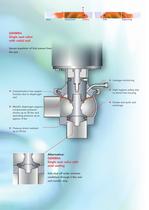

TubesComponents Valves Units Engineering Leckage monitoring Contamination free aseptic function due to diaphragm seal High hygiene safety due to dome-free housing Simple and quick seal exchange Metallic diaphragm support compensates pressure shocks up to 30 bar and operating pressure up to approx. 8 bar Pressure shock resistant up to 50 bar >

Open the catalog to page 4

GEMBRA Single seat angle valves: Contamination-free aseptic shut off GEMBRA Single seat T-valves: Contamination-free aseptic shut off and distribution GEMBRA Single seat change-over valve: Contamination-free aseptic shut off, switching and distribution >

Open the catalog to page 5

TubesComponents Valves Units Engineering Contamination free aseptic function due to diaphragm seal Metallic diaphragm support compensates pressure shocks up to approx. 30 bar and operating pressure up to approx. 8 bar Leckage monitoring High hygiene safety due to dome-free housing Simple and quick seal exchange Easy to clean k-flex sealing material offers amedium independent universal application Dead space-free location of the CIP/SIP-shutoff valves at the leakage room Contamination resistant and blending resistant separa- tion of adverse media due to safety room and leakage room between...

Open the catalog to page 6

Valve closed Valve open - Steam barrier active - Steam barrier inactive Cycle top Cycle bottom upper seat cleaning- Drain valve open lower seat cleaning- Drain valve open >

Open the catalog to page 7

TubesComponents Valves Units Engineering Technical data Installation sizes: DN 40 100tube grade according to DIN 11850 - series 2 and DIN 11866 > Technical modifications subject to alteration ַ11/07www.kieselmann.de info@kieselmann.de series A MaterialsProduct contact: 1.4404/AISI 316L Non-product contact: 1.4301/AISI 304 Sealings Product contact: k-flex with FDA-approval SurfacesProduct contact: Radius עɤ 0,8 m E-polished Product temperature: max. 95հC Sterilisation temperature: max. 140C cyclical Product pressure Valve functions: max. 8 bar Membrane pressure resistance: max. 30 bar...

Open the catalog to page 8All Kieselmann GmbH catalogs and technical brochures

-

Aseptic

4 Pages

-

Safety Valves

12 Pages

-

Single seat valves

2 Pages

-

Valve manifolds

8 Pages

-

Safety programme

12 Pages

-

Double seat valves

12 Pages

-

Single-seat valves

8 Pages

-

Folder tube programme

12 Pages