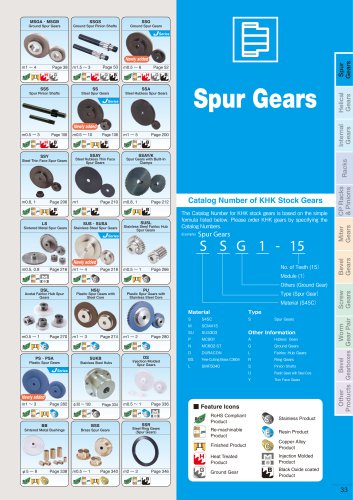

Catalog excerpts

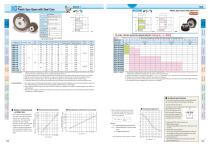

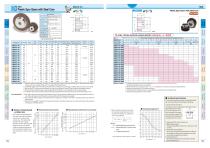

\~zl Plastic Spur Gears with Steel Core tgp ^ Other Bevel Worm Screw Bevel Miter CP Racks R . Internal Helical Spur Products Gearboxes Gear Pair Gears Gears Gears & Pinions ac s Gears Gears Gears Specifications * The precision grade of J Series products is equivalent to the value shown in the table. [Caution on Product Characteristics] © Significant variations in temperature or humidity can cause dimensional changes in plastic gears (MC Nylon gears), teeth diameter and backlash. Bore H7 \ * The product shapes of J Series items are identified by background color" Please see the section "Design of Plastic Gears" in separate technical reference book. © The allowable torques shown in the table are calculated values according to the assumed usage conditions. Please see Page 31 for more details. © When the core O.D is the same as the hub diameter, you may see some serration on the hub. There is no effect on the strength of the gear. ©Without lubrication, using plastic gears in pairs may generate heat and dilation. It is recommended to mate them with steel gears. ©The backlash values shown in the table are the theoretical values for the backlash in the normal direction of a pair of identical gears in mesh. [Caution on Secondary Operations] ©Please read "Caution on Performing Secondary Operations" (Page 32) when performing modifications and/or secondary operations for safety con cerns. KHK Quick-Mod Gears, the KHK's system for quick modification of KHK stock gears is also available. © Even though the holding strength at the material interface is designed to be stronger than the teeth, a secondary operation may weaken the holding strength. © Plastic gears are susceptible to the effects of temperature and moisture. Dimensional changes may occur while performing secondary operations and during post-machining operations. ■ Definition of Holding Strength and Safety Factor © The holding strength between the metal core and the molded material is a function of the contact area. The relationship between the core outside diameter and the radial strength (torque) is shown on the left, while the relationship between the core diameter and the resistant thrust force is shown on the right. [Caution on J series] © As available-on-request products, requires a lead-time for shipping within 2 working-days (excludes the day ordered), after placing an order. Please allow additional shipping time to get to your local distributor. © Number of products we can process for one order is 1 to 20 units. For quantities of 21 or more pieces, we need to quote price and lead time. © Keyways are made according to JIS B1301 standards, Js9 tolerance. © Certain products which would otherwise have a very long tapped hole are conterbored to reduce the length of the tap. © For products having a tapped hole, a set screw is included. © When the ambient temperature rises, obtain the temperature compensation factor, T, from the chart on the right. Also, use a safety factor of 4 to 5 in the calculation. Tal = Tmac X , ( . | X T Safety Factor Where Tal: Allowable Holding Strength at the contact surface Tmax: Maximum Holding Strength - Find from the charts on the left. T : Temperature Compensation Factor * Data supplied by Japan Polypenco Limited. ■ How is MC nylon fused to the metal core This method is superior to other conventional methods such as bolting, shrink fitting and bonding. © Outline of the procedure The surface of the core material is rolled with a 2mm pitch diamond knurl. Then one or more grooves (1 to 2mm wide and 1mm deep) are cut as shown below. The metal surface is treated prior to casting nylon in a mold. © Advantage of MC nylon with metal core 1. Wide temperature range. There are examples of wheel use in furnaces at 130 to 140° C. 2. Good dimensional stability Since nylon is fused to the whole outer surface of the metal hub, dimensional change is very small even under temperature variations. 3. Good appearance Elimination of bolts and nuts provides a cleaner physical appearance. Other Bevel Worm Screw Bevel Miter CP Racks Racks Internal Helical Spur Products Gearboxes Gear Pair Gears Gears Gears & Pinions Gears Gears Gears 128

Open the catalog to page 1

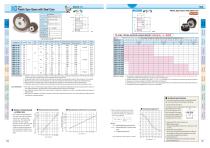

\~zl Plastic Spur Gears with Steel Core tgp ^ Plastic Spur Gears with Steel Core Other Bevel Worm Screw Bevel Miter CP Racks R . Internal Helical Spur Products Gearboxes Gear Pair Gears Gears Gears & Pinions ac s Gears Gears Gears Specifications * The precision grade of J Series products is equivalent to the value shown in the table. [Caution on Product Characteristics] © Significant variations in temperature or humidity can cause dimensional changes in plastic gears (MC Nylon gears), teeth diameter and backlash. Please see the section "Design of Plastic Gears" in separate technical...

Open the catalog to page 2

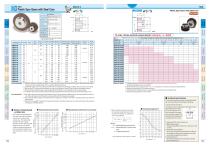

\~zl Plastic Spur Gears with Steel Core tgp ^ Plastic Spur Gears with Steel Core Other Bevel Worm Screw Bevel Miter CP Racks R . Internal Helical Spur Products Gearboxes Gear Pair Gears Gears Gears & Pinions ac s Gears Gears Gears Specifications * The precision grade of J Series products is equivalent to the value shown in the table. To order J Series products, please specify; Catalog No. + J + BORE [Caution on Product Characteristics] © Significant variations in temperature or humidity can cause dimensional changes in plastic gears (MC Nylon gears), teeth diameter and backlash. Please...

Open the catalog to page 3

\~zl Plastic Spur Gears with Steel Core tgp ^ Plastic Spur Gears with Steel Core Other Bevel Worm Screw Bevel Miter CP Racks R . Internal Helical Spur Products Gearboxes Gear Pair Gears Gears Gears & Pinions ac s Gears Gears Gears Specifications * The precision grade of J Series products is equivalent to the value shown in the table. [Caution on Product Characteristics] © Significant variations in temperature or humidity can cause dimensional changes in plastic gears (MC Nylon gears), teeth diameter and backlash. t The product shapes of J Series items are identified by background color....

Open the catalog to page 4All KHK catalogs and technical brochures

-

BB

1 Pages

-

DS

2 Pages

-

LS

1 Pages

-

SSAY series

1 Pages

-

Steel Spur Gears

16 Pages

-

SUKB

1 Pages

-

PS / PSA

5 Pages

-

SUSL

2 Pages

-

SUS / SUSA

3 Pages

-

MSGA / MSGB

6 Pages

-

SSGS

1 Pages

-

SSG

7 Pages

-

SSY

2 Pages

-

SSA

3 Pages

-

SSR series

1 Pages

-

SSS series

1 Pages

-

SSAY/K

2 Pages

-

SS series

16 Pages

-

PS series

5 Pages

-

BSS series

3 Pages

-

DSL series

2 Pages

-

MSGA ・ MSGB

6 Pages

-

Spur gears

560 Pages

Archived catalogs

-

KHK Other Products Catalogue

14 Pages

-

KHK Gearbox Catalogue

16 Pages

-

KHK Worm Gears Catalogue

56 Pages

-

KHK Screw Gear Catalogue

14 Pages

-

KHK Bevel Gear Catalogue

42 Pages

-

KHK Miter Gear Catalogue

28 Pages

-

KHK CP Rack Catalogue

18 Pages

-

KHK Rack Gear Catalogue

28 Pages

-

KHK Internal Gear Catalogue

6 Pages

-

KHK Helical Gear Catalogue

18 Pages

-

KHK Spur Gear Catalogue

224 Pages

-

KHK New Catalogue (2009, April)

48 Pages