Catalog excerpts

Units for cooking, frying, cooling for industry and trade.

Open the catalog to page 1

Units for cooking, baking and cooling for industry New developed touch screen Some touches on the control panel are enough, then the microprocessor control automatically takes over: It constantly monitors and controls precise cLima and repeatable, reliable Saving and monitoring of programs, thanks to the clear screen very simple- ■ stored programs are always reliably repeatable ■ power failure protection Automatik Ubersicht fost Oryinfl Steoi Cooking The KERRES cooking units prepare all kinds of food fully-automatic and particularly gentle with the steaming process. Natural flavouring, look...

Open the catalog to page 2

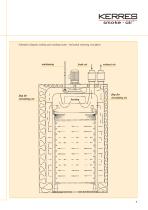

standard with three coo- king processes ■ cooking via core temperature Schematic diagram cooking chamber -electrically heated- vertical reversing circulation Subject to technical modifications.

Open the catalog to page 3

Units for cooking, baking and cooling for industry ■ ready to plug in modular design, future expandable ■ suited for both hanging products and products in a lying position ■ microprocessor control K-Touch 4012 available in many languages ■ all current heating methods ■ fibreglass upgraded insulation Whether baking or roasting of meat, sausages or other kinds of food: the KERRES baking- and roastinghouses provide the right preparations for all requirements - microprocessor-con- trolled for repeatable product quality Your benefits: ■ consistent temperature distribu- tion inside the units...

Open the catalog to page 4

Schematic diagram cooking and roasting house - horizontal reversing circulation

Open the catalog to page 5

Units for cooking, baking and cooling for industry ■ ready to plug in delivery ex works- fast installation on the spot ■ microprocessor control K-Touch 4012 available in many languages ■ cooling down to 6°C core tempe- rature possible ■ stainless steel evaporator ■ all current coolants usable The KERRES showering and intensive coolinghouses stand for modern and efficient production processes and minimum product cycle times. Imme- diately after the thermal treatment of meat, sausages and other kinds of food the product can be cooled down to a requested core temperature and packed. The air is...

Open the catalog to page 6

Schematic diagram - intensive coolinghouse waste water Subject to technical modifications.

Open the catalog to page 7

KERRES smoke-air From the fine art of smoking to an expert on food Drying, smoking, cooking, roasting and cooling. Since 1966 KERRES has developed, manufactured and sold units for processing and treatment of meat, fish, poultry and milk pro- Modular design, versatile accessories and functional operating elements enable us to provide units in the right dimension, with the right each size of business. Whether a small family business or a big indust- rial company: from the planning sta- stand by our customers - prompt, reliable with a fifty-year experience materials combined with an economi-...

Open the catalog to page 8All KERRES GmbH catalogs and technical brochures

-

HS 2850

4 Pages

-

Combined chambers

8 Pages

-

Sawdust smoke Generator

8 Pages

-

Cook tanks

3 Pages